335345435

Dec . 26, 2024 10:59 Back to list

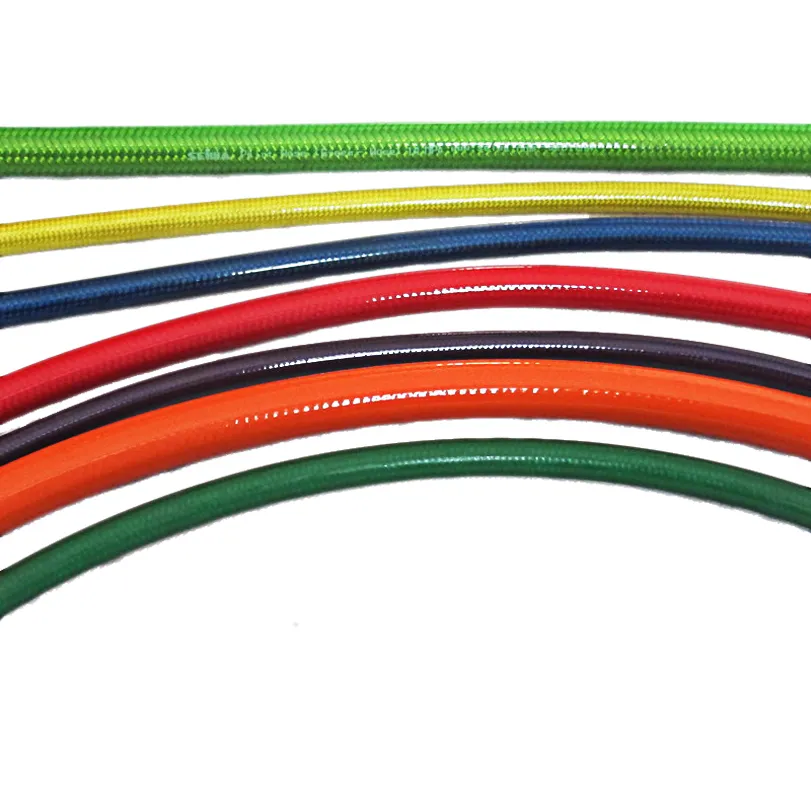

The Advantages of Thermoplastic Hoses

Thermoplastic hoses are revolutionizing the way we approach fluid and gas transfer systems in various industries. Whether it's a thermoplastic hydraulic hose for high-pressure applications or a versatile thermoplastic hose pipe for general fluid transport, these hoses offer significant benefits in terms of flexibility, durability, and efficiency. In this article, we’ll explore the key advantages of thermoplastic hoses and how they are being used across different sectors.

The Flexibility of Thermoplastic Hose

One of the primary benefits of a thermoplastic hose is its flexibility. Unlike traditional rubber hoses, which can become stiff and difficult to maneuver in certain conditions, thermoplastic hoses maintain their flexibility even in challenging environments. This makes them ideal for applications where flexibility is crucial, such as in automotive, aerospace, and agricultural industries. The ability to bend and twist without cracking or breaking allows thermoplastic hoses to be easily integrated into complex systems, improving their overall performance and ease of use.

Strength and Durability of Thermoplastic Hydraulic Hose

When it comes to high-pressure applications, the thermoplastic hydraulic hose is the go-to solution. These hoses are designed to withstand extreme pressures, making them ideal for hydraulic systems in industries like construction, manufacturing, and heavy machinery. The thermoplastic hydraulic hose is reinforced with layers of synthetic materials or steel braids, providing exceptional strength and resistance to abrasion, corrosion, and high temperatures. Whether you're working with hydraulic lifts, presses, or drilling rigs, a thermoplastic hydraulic hose offers the durability needed for demanding applications.

Versatility of Thermoplastic Hose Pipe

The thermoplastic hose pipe is known for its versatility in fluid and gas transportation. Whether you're transferring water, oil, chemicals, or gases, a thermoplastic hose pipe can handle a wide range of substances with ease. These hoses are used in various industries, from oil and gas to pharmaceuticals, thanks to their ability to resist chemical corrosion and maintain structural integrity in harsh environments. The flexibility and lightweight nature of the thermoplastic hose pipe make it easier to install and maneuver, reducing labor costs and improving operational efficiency.

Cost-Effectiveness of Thermoplastic Hoses

Another significant advantage of thermoplastic hoses is their cost-effectiveness. These hoses are often more affordable than their metal counterparts, making them an excellent choice for industries that require frequent hose replacements or large-scale systems. The lightweight nature of thermoplastic hoses also reduces transportation costs, making them a more economical choice for companies operating on a tight budget. Over time, thermoplastic hoses prove to be a more economical option due to their durability, requiring fewer replacements and maintenance.

Long-Term Benefits of Thermoplastic Hose Solutions

By investing in thermoplastic hose systems, industries can reap long-term benefits such as reduced downtime, lower maintenance costs, and improved safety. With their resistance to wear, corrosion, and high temperatures, thermoplastic hoses are built to last, even in the most demanding environments. The enhanced performance of thermoplastic hydraulic hoses and thermoplastic hose pipes means fewer breakdowns and a longer service life for the equipment, ultimately increasing operational efficiency and profitability.

Thermoplastic hoses, including thermoplastic hydraulic hoses and thermoplastic hose pipes, are essential tools for industries that require flexible, durable, and cost-effective solutions for fluid and gas transfer. With their impressive strength, resistance to corrosion, and ability to perform in extreme conditions, these hoses provide the reliability needed for both everyday and high-pressure applications. Whether you're involved in construction, agriculture, or automotive industries, investing in thermoplastic hoses will help improve operational efficiency and long-term performance.

-

LPG Hose: Choosing the Right Hose for Safe, Reliable Gas Transfer

NewsAug.07,2025

-

Industrial Hose: Types, Applications, and Where to Find Reliable Suppliers

NewsAug.07,2025

-

Hydraulic Hose Pipe: Types, Pricing, and How to Source the Right One

NewsAug.07,2025

-

Hydraulic Fittings: Types, Customization, and Where to Source Them

NewsAug.07,2025

-

High Pressure Washer Hoses: Buying Guide, Specs, and Supplier Insights

NewsAug.07,2025

-

Choosing the Right Gasoline Hose: Flexibility, Resistance, and Supply Options

NewsAug.07,2025