335345435

Aug . 07, 2025 10:53 Back to list

Industrial Hose: Types, Applications, and Where to Find Reliable Suppliers

In heavy industry, manufacturing, construction, and logistics, the humble industrial hose does more than connect machinery. It carries everything from air and water to fuel, chemicals, abrasive media, food products, and high-temperature steam. The wrong hose choice can result in leaks, downtime, or even safety incidents—so choosing the right one is a mission-critical task.

Whether you're sourcing a specific industrial hose for sale, evaluating different specifications, or comparing industrial hose suppliers, this guide covers the essential types, applications, and pricing insights to help you make the right decision.

What Is an Industrial Hose?

An industrial hose is a flexible conduit designed to transport fluids, gases, or solids in demanding industrial environments. Unlike standard garden or utility hoses, industrial hoses are engineered for higher pressures, extreme temperatures, chemical compatibility, and mechanical stress.

Industrial hoses are used in:

Construction and mining

Petrochemical processing

Food and beverage plants

HVAC and water treatment

Marine and shipbuilding

Manufacturing and automation

Types of Industrial Hoses

There are dozens of hose types, each designed for specific materials, pressure ranges, and working conditions. Here’s a breakdown of the most common types of industrial hoses:

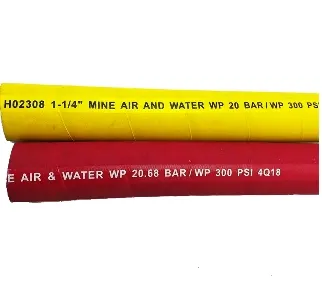

1. Air Hose

For pneumatic tools, compressors, and spray guns

Usually made of PVC, EPDM, or rubber

Pressure rated (150–300 PSI) and highly flexible

2. Water Discharge & Suction Hose

Moves large volumes of water for irrigation, pumping, or dewatering

Rubber or PVC with textile or steel reinforcement

Sizes range from 1" to 12"+ in diameter

3. Fuel & Oil Hose

Handles diesel, gasoline, kerosene, hydraulic oils

Inner lining made of nitrile rubber (NBR) or Viton

Often grounded to dissipate static electricity

4. Chemical Hose

Designed for highly corrosive acids, bases, solvents

Fluoropolymer or UHMWPE liners for chemical resistance

Must match the chemical compatibility chart

5. Steam Hose

Transfers saturated steam at high temperature and pressure

EPDM or chlorobutyl rubber, reinforced with braided wire

Rated for up to 450°F (232°C) and 250 PSI+

6. Food Grade Hose

For dairy, beverage, syrup, or edible oil transfer

Made from FDA-compliant materials (white EPDM, nitrile, or Teflon)

Odorless, tasteless, and easy to sanitize

7. Abrasive Material Hose

Used for sandblasting, concrete, or grain transfer

Reinforced with abrasion-resistant rubber or ceramic lining

Inner wall designed to handle particle wear

8. Ducting Hose

For air movement, fume extraction, or dust collection

Lightweight and flexible (often PVC, polyurethane, or silicone)

Can be compressible for storage

Each hose comes with its own fittings, coupling types, pressure ratings, bend radius, and temperature limits.

Key Specifications to Evaluate

Before purchasing an industrial hose, consider:

|

Specification |

Why It Matters |

|

Size (ID/OD) |

Must match your fittings and flow requirements |

|

Working pressure |

Rated in PSI or bar – critical for safety |

|

Temperature range |

Both ambient and internal fluid temps |

|

Material compatibility |

Hose lining must resist the material being transferred |

|

Reinforcement type |

Braided, spiral, or textile – affects flexibility and burst strength |

|

Certifications |

FDA, ISO, SAE, MSHA, or UL depending on industry |

Industrial Hose Prices: What to Expect

Industrial hose prices vary widely depending on type, size, and spec. Here's a rough estimate (USD/meter, 2025):

|

Hose Type |

Diameter |

Price Range (USD/meter) |

|

General air/water hose |

1/2"–1" |

$2.00 – $6.00 |

|

Fuel/oil hose |

3/4"–2" |

$5.00 – $12.00 |

|

Steam hose (250 PSI) |

1/2"–2" |

$10.00 – $25.00 |

|

Chemical hose (UHMWPE) |

1"–3" |

$12.00 – $35.00 |

|

Food-grade hose |

1"–4" |

$10.00 – $28.00 |

|

Abrasive material hose |

2"–6" |

$15.00 – $40.00+ |

Preassembled hoses with fittings (camlocks, flanges, quick-connects) may add $10–$50 per hose, depending on length and coupling type.

Choosing the Right Industrial Hose Supplier

A trustworthy industrial hose supplier should offer:

ISO or ASTM-certified products

Application-specific guidance (chemical resistance charts, pressure drop info)

Inventory availability for urgent orders

Custom assembly services

Transparent lead times and warranty policies

For regional markets, many certified OEMs in China, India, Germany, and the U.S. offer competitive pricing and rapid turnaround.

Industrial Hose FAQs

Q1: What’s the difference between braided and spiral hose reinforcement?

A: Braided hoses are more flexible and used for lower-pressure systems. Spiral-reinforced hoses are stiffer but can handle much higher pressure and burst resistance.

Q2: Can I use a water hose to transfer fuel?

A: No. Water hoses are not chemically resistant or pressure-rated for hydrocarbons. Always use fuel-rated hoses.

Q3: What certifications should food-grade hoses have?

A: Look for FDA, USDA, or 3A sanitary compliance, depending on your industry. Hose material should be non-toxic, odorless, and easy to clean.

Q4: Do industrial hoses come with fittings?

A: Not always. You can order bare hose by the meter, or request assemblies with specific fittings like camlocks, flanges, or quick-connects.

Q5: Where can I buy industrial hose in bulk or OEM?

A: Contact hose manufacturers directly or work with industrial distributors that offer OEM or private label options. Bulk orders often come on reels or pallets.

-

LPG Hose: Choosing the Right Hose for Safe, Reliable Gas Transfer

NewsAug.07,2025

-

Industrial Hose: Types, Applications, and Where to Find Reliable Suppliers

NewsAug.07,2025

-

Hydraulic Hose Pipe: Types, Pricing, and How to Source the Right One

NewsAug.07,2025

-

Hydraulic Fittings: Types, Customization, and Where to Source Them

NewsAug.07,2025

-

High Pressure Washer Hoses: Buying Guide, Specs, and Supplier Insights

NewsAug.07,2025

-

Choosing the Right Gasoline Hose: Flexibility, Resistance, and Supply Options

NewsAug.07,2025