Industrial Hose

Industrial hoses are essential components in various industries, offering significant advantages that contribute to the efficiency, safety, and versatility of operations. One of the primary benefits of industrial hoses is their ability to handle a wide range of fluids, including water, chemicals, gases, and abrasive materials. This versatility makes them indispensable in industries such as manufacturing, agriculture, mining, and construction, where the safe and effective transfer of materials is critical.

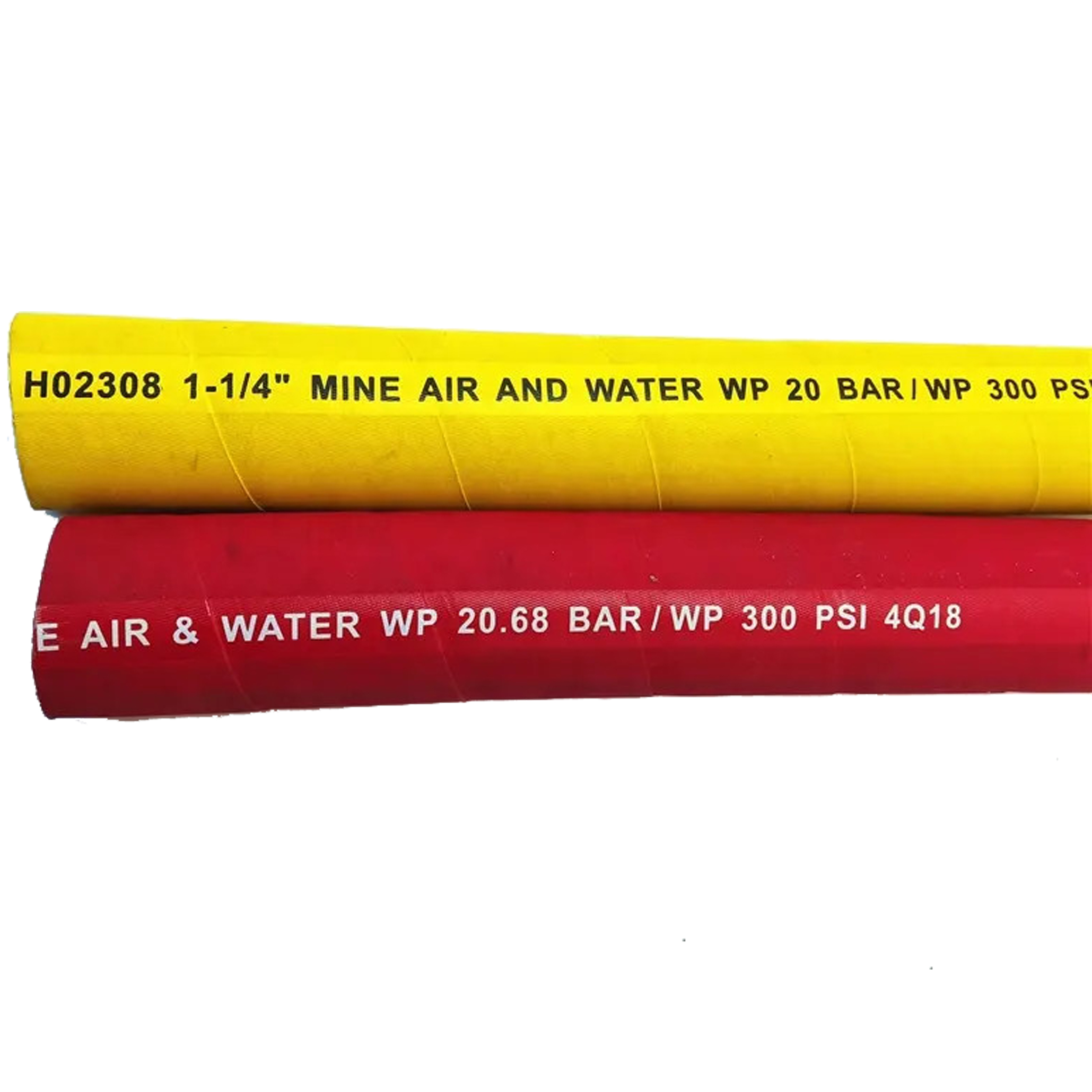

Durability is another key advantage of industrial hoses. Constructed from high-quality materials like rubber, PVC, or composite materials, these hoses are designed to withstand harsh environmental conditions, extreme temperatures, and high pressures. This robust construction ensures long service life, reducing the need for frequent replacements and minimizing downtime, which is crucial for maintaining continuous operations in industrial settings.

Flexibility is another advantage of industrial hoses, as it allows them to be used in various applications and configurations. Whether it's navigating tight spaces or accommodating complex layouts, industrial hoses can be tailored to meet specific operational requirements. This adaptability makes them a preferred choice for industries that demand customized solutions to address unique challenges.

Safety is also a significant consideration, and industrial hoses are engineered with features that enhance workplace safety. For example, anti-static and fire-resistant hoses are available for use in hazardous environments, reducing the risk of accidents and ensuring compliance with safety regulations. Additionally, industrial hoses can be equipped with couplings and fittings that provide secure connections, preventing leaks and ensuring reliable performance.

What Is an Industrial Hose?

Industrial hoses are essential components in various industries, designed to transport fluids and gases under high pressure and extreme conditions. These specialized hoses are manufactured from durable materials to withstand the rigors of industrial applications, ensuring safety and efficiency in operations.

Typically made from rubber, thermoplastics, or other composite materials, industrial hoses are utilized in sectors such as construction, agriculture, manufacturing, and chemical processing. Their construction allows them to handle a wide range of substances, including water, oil, chemicals, and air. Depending on the application, these hoses can be reinforced with layers of fiber or steel wire, enhancing their strength and resistance to abrasion, heat, and chemical attack.

One of the most significant advantages of industrial hoses is their flexibility. This characteristic makes them easy to maneuver in tight spaces or around equipment, contributing to a more efficient workflow. Furthermore, the design of industrial hoses can vary, offering options such as suction hoses, discharge hoses, and specialty hoses designed for particular tasks or materials.

Types of Industrial Hoses

Industrial hoses are essential components in various industries, allowing for the transfer of liquids, gases, and solids. With countless applications ranging from construction to food processing, choosing the right industrial hose is crucial.

1. General Purpose Industrial Hoses

General-purpose industrial hoses are versatile and can be used in a wide range of applications. Made from a variety of materials, including rubber and PVC, these hoses can handle water, air, and certain chemicals. They are lightweight yet durable, making them an excellent choice for both indoor and outdoor environments.

2. Chemical Transfer Hoses

Chemical transfer hoses are imperative when it comes to transferring hazardous materials. These hoses are specially designed to withstand corrosive substances, ensuring safety during transport. Typically constructed with synthetic rubber or thermoplastics, they come with various lining options that make them suitable for specific chemicals.

3. Food and Beverage Hoses

In the food and beverage industry, sanitation is key. Food-grade industrial hoses are designed to meet stringent FDA regulations and ensure the safe transfer of consumables. These hoses are made from materials that resist microbial growth and are easy to clean, making them ideal for dairy, beverage, and food processing applications.

4. Hydraulic Hoses

Industrial hoses play a vital role in hydraulic systems. Hydraulic hoses are engineered to withstand high pressure and extreme conditions. They are commonly used in heavy machinery and equipment, providing critical support in various applications.

5. Specialty Hoses

Lastly, specialty hoses cater to specific industrial needs. Whether it’s extreme temperature resistance, abrasion resistance, or unique chemical compatibility, there is an industrial hose designed to meet those requirements.

Industrial Hose Application

The primary function of industrial hoses is to transport fluids, gases, and other materials, ranging from water and chemicals to concrete and oil. The choice of hose material is crucial, as it must withstand the specific conditions it will face - such as high pressures, extreme temperatures, and exposure to harmful substances. Common materials include rubber, PVC, and various composites, each tailored for different industrial hose applications.

One notable area of industrial hose application is in construction. Hoses are used to pump concrete, deliver water, and transfer various materials, ensuring projects run smoothly. Similarly, in the agricultural sector, hoses facilitate irrigation and the application of fertilizers, improving crop yield and efficiency.

Another major application is in the automotive industry, where hoses are essential for fuel delivery, coolant transfer, and exhaust systems. The reliability of these hoses can often be the difference between a successful operation and costly downtime.

Safety is paramount in industrial hose applications. Regular inspection and maintenance are vital to prevent leaks and ruptures that could lead to accidents. Companies must choose hoses that are certified for their specific use, ensuring they meet all safety regulations and industry standards.

What Is the Difference Between Industrial and Hydraulic Hoses?

Industrial hoses are designed to transport a variety of substances, ranging from air and water to chemicals and petroleum products. Typically constructed from durable materials like rubber, PVC, or polyurethane, these hoses can withstand a wide range of pressures and temperatures. Their flexibility, versatility, and ability to accommodate different fluids make them widely used across industries such as construction, agriculture, and manufacturing.

In addition, industrial hoses come in various sizes and lengths, allowing for customized solutions to fit distinct operational needs. They are vital for applications where mobility and adaptability are required, ensuring seamless functionality in demanding

On the other hand, hydraulic hoses are specifically engineered for high-pressure applications. They are primarily used in hydraulic systems to transmit hydraulic fluid, which powers machinery and equipment. The construction of hydraulic hoses typically includes multiple layers of reinforcement, often combining synthetic rubber with high-strength wire braids or spirals to ensure safety under pressure.

Hydraulic hoses are crucial in industries such as automotive and heavy machinery, where precise control and maximum pressure ratings are essential. Their robust design aids in preventing leaks and burst failures, which can lead to severe operational hazards.