335345435

Aug . 07, 2025 00:20 Back to list

Premium Wire Braided Hydraulic Hose - Steel Reinforced for Durability

In the dynamic realm of modern industry, where precision, power, and reliability are paramount, hydraulic systems stand as the backbone of countless operations. From heavy construction equipment to advanced manufacturing machinery, the efficiency and safety of these systems hinge critically on the quality of their components. Among these, the hydraulic hose plays a pivotal role, acting as the circulatory system that conveys pressurized fluid, transforming raw power into controlled motion. Specifically, the wire braided hydraulic hose has emerged as a superior solution, engineered to withstand the most demanding conditions while delivering consistent, high-performance results. This comprehensive guide delves into the intricate world of wire braided hydraulic hose, exploring its technical prowess, manufacturing excellence, diverse applications, and the critical factors that make it an indispensable asset across various sectors.

Industry Trends and the Evolving Landscape of Hydraulic Hoses

The global hydraulic hose market is experiencing significant growth, driven by an increasing demand for industrial machinery, robust infrastructure development, and advancements in automation across sectors like construction, agriculture, and manufacturing. Reports indicate the global hydraulic hose market size, valued at approximately USD 2.8 billion in 2023, is projected to reach USD 4.5 billion by 2030, with a Compound Annual Growth Rate (CAGR) of around 5.5%. This expansion is fueled by several key trends:

- Miniaturization and Compact Design: A growing preference for smaller, more efficient hydraulic systems necessitates hoses that can handle high pressures within confined spaces, pushing the demand for compact designs like SAE 100 R17.

- Sustainability and Eco-Friendly Materials: Increasing environmental regulations are prompting manufacturers to explore greener materials and processes, focusing on reduced energy consumption and recyclable components.

- Enhanced Durability and Longevity: Industries are demanding hoses with extended service lives, capable of resisting abrasion, corrosion, and extreme temperatures, thereby minimizing downtime and maintenance costs.

- Smart Hydraulics: Integration of sensors and IoT (Internet of Things) for predictive maintenance and real-time performance monitoring is gaining traction, requiring hoses that can accommodate these technological advancements.

- Emerging Markets: Rapid industrialization in developing economies is creating new avenues for hydraulic hose manufacturers.

In this evolving landscape, the steel wire braided hydraulic hose, particularly designs compliant with SAE standards, remains at the forefront due to its unmatched strength-to-weight ratio and proven reliability in high-pressure environments.

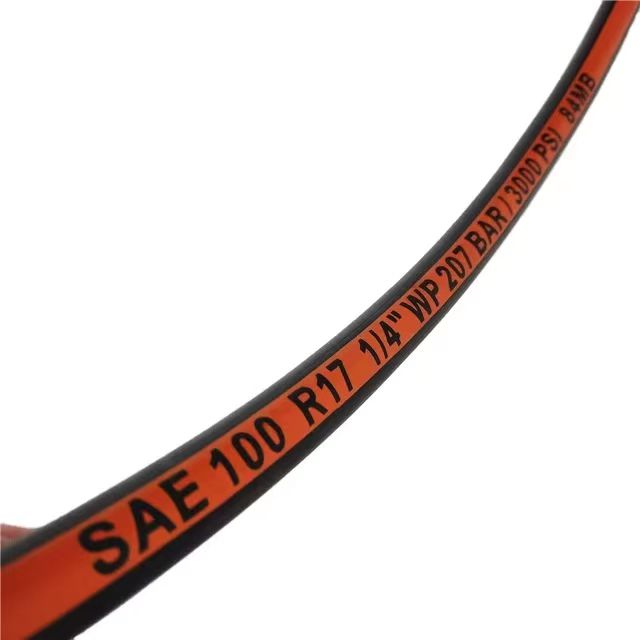

Unpacking the SAE 100 R17 Black Smooth Cover Hydraulic Hose

Our featured product, the SAE 100 R17 Black Smooth Cover Hydraulic Hose, represents the pinnacle of compact and high-performance hydraulic hose technology. Designed for systems where space is at a premium but high pressure resistance is non-negotiable, this hose combines advanced materials with meticulous manufacturing processes to deliver exceptional operational reliability. Its smooth black cover is not merely aesthetic; it offers superior abrasion and weather resistance, crucial for extending the hose's lifespan in harsh operational environments.

Key Specifications and Parameters

The SAE 100 R17 standard defines a compact, lightweight hydraulic hose designed for high-pressure service with a tighter bend radius than traditional R1 or R2 hoses. This makes it ideal for routing in confined spaces without compromising performance. Below are typical parameters for the SAE 100 R17 hose:

| Feature | Description | Typical Range/Value |

|---|---|---|

| Standard | SAE 100 R17 | Meets or Exceeds SAE J517 100R17 |

| Reinforcement | Single steel wire braid | High-tensile steel wire |

| Inner Tube Material | Oil-resistant synthetic rubber | NBR (Nitrile Butadiene Rubber) or similar |

| Outer Cover Material | Weather, oil, abrasion-resistant synthetic rubber | SBR/EPDM blend or similar, Black Smooth Finish |

| Working Pressure | High-pressure capabilities across all sizes | 207 - 276 Bar (3000 - 4000 PSI) for various IDs |

| Burst Pressure | Minimum 4x Working Pressure | Typically 828 - 1104 Bar (12000 - 16000 PSI) |

| Temperature Range | Optimal performance in varied climates | -40°C to +100°C (-40°F to +212°F) |

| Bend Radius | Significantly tighter than R1/R2 | Min. 50-120mm (2-4.7 inches) depending on ID |

| Applications | Hydraulic lines for compact heavy machinery | Construction, agriculture, material handling |

The Art and Science of Manufacturing Wire Braided Hydraulic Hose

The creation of a high-performance wire braided hydraulic hose is a complex, multi-stage process that combines advanced material science with precision engineering. Each step is critical to ensuring the hose meets stringent international standards like ISO and SAE, guaranteeing its reliability, durability, and safety under extreme conditions. Here's a detailed look at the manufacturing journey:

Manufacturing Process Flow

Inner Tube Extrusion

The process begins with the extrusion of the inner tube. This critical component is made from a high-quality, oil-resistant synthetic rubber (typically NBR - Nitrile Butadiene Rubber) designed to be chemically compatible with various hydraulic fluids, including petroleum-based, water-glycol, and water-oil emulsions. The rubber compound is carefully mixed and then fed into an extruder, where it is heated and forced through a die to form a seamless, precise-diameter tube. The quality of this inner tube directly impacts the hose's fluid compatibility and resistance to degradation.

↓

Textile Layer Application (Optional/Adhesion Layer)

For some constructions, or to enhance adhesion between layers, a textile wrap or adhesion layer may be applied over the inner tube. This step ensures superior bonding between the rubber and the subsequent steel wire braid, preventing delamination under pressure and impulse cycling. This layer can also provide a cushion for the wire braid.

↓

Steel Wire Braiding

This is the defining stage for wire braided hydraulic hose. High-tensile strength steel wire is precisely braided around the inner tube (or textile layer) at a specific angle, typically between 50 to 55 degrees relative to the hose's longitudinal axis. This braiding angle is crucial as it optimizes the hose's ability to resist internal pressure while maintaining flexibility. For SAE 100 R17, a single layer of such braiding is used, meticulously applied by specialized braiding machines. The wire quality (e.g., carbon steel with high tensile strength) and the consistency of the braiding process directly determine the hose's working pressure rating and its resistance to expansion under pressure.

↓

Outer Cover Extrusion

Once the wire reinforcement is in place, an outer cover is extruded over the braided layer. This cover is typically made from an abrasion-resistant, weather-resistant, and oil-resistant synthetic rubber compound (like a blend of SBR/EPDM) designed to protect the internal components from external damage, environmental degradation (UV, ozone), and chemical exposure. For the SAE 100 R17 Black Smooth Cover hose, this layer is extruded to a smooth finish, enhancing its cleanability and reducing friction in tight installations.

↓

Vulcanization (Curing)

The assembled hose then undergoes a vulcanization process, where it is heated under controlled conditions. This curing process chemically cross-links the rubber compounds, transforming the pliable raw materials into a durable, elastic, and resilient finished product. Vulcanization gives the hose its final mechanical properties, including its pressure resistance, temperature stability, and overall structural integrity.

↓

Testing and Quality Control

After vulcanization, every length of hose undergoes rigorous testing to ensure it meets or exceeds industry standards (ISO 18752, SAE J517, EN 857, etc.) and specific performance criteria. Key tests include:

- Proof Pressure Test: Hoses are subjected to a specified pressure (typically 2x working pressure) to check for leaks or structural weaknesses.

- Burst Pressure Test: Hoses are pressurized to destruction to confirm they meet minimum burst pressure requirements.

- Impulse Testing: Hoses are subjected to rapid pressure cycles at varying temperatures to simulate real-world operating conditions and assess fatigue resistance. This is crucial for evaluating service life.

- Dimensional Checks: Inner diameter, outer diameter, and concentricity are measured.

- Adhesion Test: Strength of the bond between layers is verified.

- Flexibility and Bend Radius Test: To confirm the hose meets specified bend radius requirements without kinking or deforming.

- Material Properties Test: Including tensile strength, elongation, and hardness of rubber components.

Only hoses that pass all these stringent tests are marked and prepared for dispatch, ensuring ultimate reliability in the field.

Figure 1: Illustration of a multi-layer hydraulic hose construction, highlighting the inner tube, steel wire reinforcement, and outer cover.

Enhanced Advantages in Typical Applications

The meticulous manufacturing process imbues the wire braided hydraulic hose with distinct advantages that translate into tangible benefits in various application scenarios:

- Energy Efficiency: A well-designed hydraulic hose minimizes pressure drop and energy loss during fluid transmission. The smooth bore of our SAE 100 R17 hose ensures laminar flow, reducing friction and contributing to overall system energy efficiency. This can lead to significant fuel or electricity savings over the operational lifespan of heavy machinery.

- Superior Corrosion Resistance: The robust synthetic rubber outer cover provides excellent resistance to environmental factors such as moisture, chemicals, oils, and UV radiation. This makes the hose highly suitable for outdoor applications, marine environments, and industrial settings where exposure to corrosive agents is common, thereby extending its service life considerably compared to hoses with less resilient covers.

- Extended Service Life: By adhering to strict ISO and SAE standards and employing rigorous testing, the hose is designed for exceptional longevity. Its resistance to impulse cycles, abrasion, and kinking means fewer replacements, less downtime, and reduced maintenance costs. This is particularly vital in high-stakes industries where equipment availability directly impacts productivity.

- Durability in Extreme Conditions: The high-tensile steel wire braid reinforcement provides unparalleled strength, allowing the hose to operate reliably under high continuous and fluctuating pressures. Combined with its wide operating temperature range, this hose maintains its integrity and performance in environments from sub-zero temperatures to high heat applications.

- Compactness and Flexibility: The SAE 100 R17's compact design and tighter bend radius simplify routing in crowded machine compartments, reducing installation complexity and potential for kinking, which is a common failure mode in less flexible hoses.

Application Scenarios for Wire Braided Hydraulic Hose

The versatility and robust performance of wire braided hydraulic hose make it an indispensable component across a multitude of industries. Its ability to handle high pressures, extreme temperatures, and abrasive environments ensures reliable power transmission in the most demanding applications. Here are some key sectors and typical uses:

- Construction and Heavy Equipment: Excavators, bulldozers, cranes, loaders, and concrete pumps rely heavily on hydraulic systems. Steel wire braided hydraulic hose is crucial for controlling hydraulic cylinders that operate booms, buckets, and other attachments. Its durability resists wear and tear from constant movement and harsh outdoor conditions.

- Mining Industry: In underground and open-pit mining operations, equipment like drilling rigs, continuous miners, and large haul trucks require robust hydraulic lines that can withstand severe abrasion, impact, and corrosive environments. Hoses used here must also be flame-resistant and have excellent pressure retention.

- Agriculture: Tractors, combines, sprayers, and other farm machinery utilize hydraulics for steering, lifting, and operating implements. Hoses must endure exposure to chemicals, UV radiation, and variable temperatures, making the smooth, weather-resistant cover of SAE 100 R17 particularly beneficial.

- Oil and Gas (Onshore & Offshore): From drilling rigs to wellhead equipment and offshore platforms, hydraulic hoses are essential for fluid transfer and power. They must resist highly corrosive fluids, extreme pressures, and harsh marine environments. Specialized hoses are often required for specific oil and gas applications, though standard wire braided hydraulic hose is common for general utility lines.

- Manufacturing and Industrial Machinery: Hydraulic presses, injection molding machines, machine tools, and robotics in manufacturing plants depend on precise and reliable hydraulic power. Wire braided hydraulic hose ensures consistent performance for repetitive, high-cycle operations.

- Marine and Shipbuilding: Hydraulic systems control steering, winches, cargo doors, and other vital functions on ships and marine vessels. Hoses must withstand saltwater corrosion, constant vibration, and varying temperatures.

- Waste Management: Compacting equipment, garbage trucks, and recycling machinery use hydraulics extensively. Hoses here face rigorous demands from high pressure, abrasive waste materials, and outdoor exposure.

- Forestry: Harvesters, forwarders, and feller bunchers operate in challenging terrains and weather conditions. Hydraulic hoses are integral to their cutting, lifting, and processing functions, requiring high durability and flexibility.

The adaptability of wire braided hydraulic hose to such a diverse range of applications underscores its fundamental importance in the global industrial landscape, acting as a critical enabler of efficiency and productivity across sectors.

Comparative Analysis: Wire Braided Hydraulic Hose Parameters

To further illustrate the technical advantages and distinctions within the wire braided hydraulic hose family, it's beneficial to compare different common standards. While our focus is on SAE 100 R17, understanding its position relative to other types like R1 and R2 highlights its unique value proposition, particularly for compact systems requiring high pressure and tight bend radii.

| Parameter | SAE 100 R1 (Single Wire Braid) | SAE 100 R2 (Double Wire Braid) | SAE 100 R17 (Compact Single Wire Braid) |

|---|---|---|---|

| Reinforcement | 1 layer of high-tensile steel wire braid | 2 layers of high-tensile steel wire braid | 1 layer of high-tensile steel wire braid (optimized) |

| Max Working Pressure (e.g., for 1/2" ID) | 210 Bar (3050 PSI) | 350 Bar (5000 PSI) | 276 Bar (4000 PSI) |

| Min Burst Pressure (e.g., for 1/2" ID) | 840 Bar (12200 PSI) | 1400 Bar (20000 PSI) | 1104 Bar (16000 PSI) |

| Operating Temperature Range | -40°C to +100°C (-40°F to +212°F) | -40°C to +100°C (-40°F to +212°F) | -40°C to +100°C (-40°F to +212°F) |

| Min Bend Radius (e.g., for 1/2" ID) | 125 mm (4.9 inches) | 230 mm (9.1 inches) | 100 mm (3.9 inches) |

| Outer Diameter (e.g., for 1/2" ID) | ~21.4 mm (~0.84 inches) | ~23.8 mm (~0.94 inches) | ~19.8 mm (~0.78 inches) (More compact) |

| Flexibility | Good | Moderate | Excellent (due to compact design) |

| Applications | Medium pressure hydraulic lines | High pressure hydraulic lines, heavy duty | High pressure in compact spaces, mobile equipment |

This table clearly illustrates that while SAE 100 R17 uses a single wire braided hydraulic hose layer like R1, its optimized design allows it to achieve significantly higher working pressures—approaching R2 levels—while maintaining a remarkably tighter bend radius and a smaller outer diameter. This combination makes it exceptionally well-suited for modern, compact machinery where traditional R2 hoses might be too bulky or inflexible for routing.

Choosing Your Partner: Manufacturer Comparison and Customization Solutions

Selecting the right supplier for your wire braided hydraulic hose needs is as critical as choosing the hose itself. A reputable manufacturer doesn't just sell products; they offer solutions, expertise, and unwavering support. When comparing manufacturers, consider the following:

Key Factors for Manufacturer Comparison

- Expertise and Experience: Look for manufacturers with a long-standing history in the hydraulic hose industry. Years of operation signify accumulated knowledge, refined processes, and a deep understanding of market needs and technical challenges.

- Quality Certifications and Compliance: Verify adherence to international standards such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and specific product standards like SAE J517, EN 853, or EN 857. These certifications are robust indicators of a manufacturer's commitment to consistent quality and reliable production.

- R&D and Innovation: A forward-thinking manufacturer invests in research and development to create new materials, improve existing products, and address evolving industry demands (e.g., higher pressure ratings, better chemical compatibility, sustainable options).

- Manufacturing Capabilities: Assess their production capacity, advanced machinery, and rigorous in-house testing facilities. A manufacturer with comprehensive testing capabilities ensures every batch meets performance specifications before leaving the factory.

- Product Range and Customization: A broad product portfolio, coupled with the ability to offer tailored solutions, demonstrates flexibility and responsiveness to unique customer requirements.

- Technical Support and After-Sales Service: Excellent customer support, including technical assistance, troubleshooting, and efficient handling of inquiries, is vital for long-term partnerships.

- Global Presence and Supply Chain: For international operations, a manufacturer with a robust global distribution network can ensure timely delivery and consistent supply, minimizing logistical hurdles.

Tailored Customization Solutions

Understanding that off-the-shelf solutions don't always fit every specific requirement, we specialize in providing comprehensive customization options for our wire braided hydraulic hose. This bespoke approach ensures that your hydraulic system operates at its peak efficiency, safety, and longevity. Our customization capabilities include:

- Specific Lengths and Assemblies: Hoses can be cut to precise lengths and pre-assembled with a wide array of end fittings (e.g., JIC, ORFS, BSP, DIN) to ensure a perfect fit for your equipment, reducing installation time and potential for leaks.

- Specialized Outer Covers: Beyond the standard black smooth cover, we can provide hoses with enhanced resistance to specific environmental challenges such as extreme abrasion, flame, UV radiation, or particular chemicals.

- Custom Branding and Marking: Hoses can be marked with your company logo, part numbers, or specific identifiers for easier inventory management and brand consistency.

- Multi-Line Bundles: For complex machinery, multiple hydraulic lines can be bundled together within a single protective sleeve, simplifying routing, improving aesthetics, and adding an extra layer of protection.

- Fluid Compatibility: While standard hoses handle common hydraulic fluids, we can engineer hoses with inner tube materials specifically designed for unusual or aggressive fluid types, ensuring chemical compatibility and preventing premature degradation.

- Pressure and Temperature Optimization: For applications demanding performance beyond standard specifications, we can consult on and potentially design hoses with optimized reinforcement or material compounds to meet higher pressure or extreme temperature requirements.

By offering these tailored solutions, we empower our clients to achieve optimal performance and maximum operational efficiency from their hydraulic systems, ensuring that every steel wire braided hydraulic hose is perfectly aligned with its intended purpose.

Real-World Impact: Application Cases and Success Stories

The true value of a wire braided hydraulic hose is best demonstrated through its performance in challenging, real-world scenarios. Here are hypothetical yet illustrative application cases showcasing the advantages of our SAE 100 R17 Black Smooth Cover Hydraulic Hose:

Case Study 1: Heavy-Duty Excavator in Quarry Operations

A large-scale quarry operation faced recurring issues with hydraulic hose failures on their excavators. The existing hoses, while meeting basic pressure requirements, suffered from rapid abrasion due to constant rubbing against rock and machine components, leading to frequent unscheduled downtime. The tight spaces within the excavator's boom also made routing difficult, resulting in kinking and premature wear.

Outcome: Over a 12-month period, the quarry reported a 40% reduction in hydraulic hose-related breakdowns for the excavators equipped with R17 hoses. This translated to a significant increase in operational uptime (estimated at an additional 150 hours per excavator annually) and a measurable decrease in maintenance costs, proving the long-term value and durability of the steel wire braided hydraulic hose in extreme environments.

Case Study 2: Agricultural Sprayer in Harsh Climates

A large agricultural enterprise operating in regions with both extreme summer heat and harsh winters experienced issues with their sprayer's hydraulic hoses. The hoses frequently hardened and cracked in cold weather, or degraded prematurely under intense UV exposure and chemical splashes from pesticides and fertilizers. Hose failures during critical spraying windows led to substantial crop losses.

Outcome: The farm observed a dramatic reduction in hose failures across multiple spraying seasons. The improved chemical resistance extended hose life by over 50%, while the temperature stability eliminated cold-weather cracking and hot-weather softening. This led to consistent sprayer operation, minimizing downtime during critical planting and harvesting periods, and ensuring optimal crop yield.

Figure 2: Wire braided hydraulic hose lines integrated into heavy machinery, demonstrating compact routing and durability.

Case Study 3: Industrial Press with Space Constraints

A manufacturing plant utilized a series of high-tonnage industrial presses, where limited space around the hydraulic manifold made hose routing a significant challenge. The existing hoses were prone to kinking near fittings, which caused flow restrictions and localized stress points, leading to premature failure and costly production halts.

Outcome: By resolving the kinking problem, the plant experienced a notable reduction in hydraulic system pressure drops and a significant increase in hose lifespan within the presses. This led to fewer hose replacements, reduced maintenance labor, and consistent operational uptime for critical manufacturing processes, enhancing overall productivity and cost-efficiency.

These case studies underscore the practical benefits and return on investment provided by high-quality wire braided hydraulic hose, particularly when matched to the specific demands of the application.

Building Trust: Quality Assurance, Deliverability, and Customer Support

At Dayi Rubber Hose, our commitment extends beyond delivering exceptional products. We prioritize trust, transparency, and a robust support system to ensure complete customer satisfaction. Our operational ethos is built upon stringent quality control, reliable logistics, and proactive customer engagement.

Commitment to Quality (Authoritativeness & Trustworthiness)

Our manufacturing facilities operate under strict adherence to internationally recognized quality management systems. We are proudly certified with ISO 9001:2015, a testament to our systematic approach to consistently providing products and services that meet customer and regulatory requirements. This certification encompasses every stage, from raw material sourcing to final inspection. Our wire braided hydraulic hose products, including the SAE 100 R17, are manufactured to comply with or exceed standards such as SAE J517, EN 853, and ISO 18752, ensuring global compatibility and performance reliability.

We work with accredited third-party laboratories for independent testing and verification of our product performance, including burst pressure, impulse cycling, and material compatibility. Our long-standing relationships with leading industrial partners and a service history spanning over two decades further solidify our reputation as an authoritative and trustworthy provider in the hydraulic hose industry.

Reliable Deliverability

Understanding the critical nature of timely supply in industrial operations, we have streamlined our logistics and supply chain. Our standard delivery lead time for in-stock wire braided hydraulic hose products, such as the SAE 100 R17, is typically 7-14 business days, depending on order volume and destination. For large-scale or customized orders, specific timelines will be communicated and agreed upon during the quotation phase. We offer various shipping options, including express delivery for urgent requirements, to ensure your operations face minimal disruption.

Comprehensive Warranty and Customer Support

We stand by the quality and performance of our products. All our wire braided hydraulic hose products come with a 12-month limited warranty against manufacturing defects from the date of purchase. This warranty underscores our confidence in our manufacturing processes and materials. In the unlikely event of a product issue, our dedicated customer support team is readily available to assist.

Our technical support team comprises experienced engineers and product specialists who can provide expert guidance on hose selection, installation best practices, troubleshooting, and maintenance. We offer multiple channels for support, including phone, email, and online inquiry forms, ensuring that assistance is just a click or call away. Our goal is not just to sell a product, but to build lasting partnerships based on mutual trust and sustained performance.

Frequently Asked Questions (FAQ) about Wire Braided Hydraulic Hose

Q1: What does "SAE 100 R17" signify, and how is it different from SAE 100 R1 or R2?

A1: SAE 100 R17 is an industry standard (Society of Automotive Engineers) for compact, lightweight hydraulic hoses with a single steel wire braid reinforcement. Its key distinction lies in its ability to achieve high working pressures (comparable to some R2 hoses) while offering a significantly tighter bend radius and smaller outer diameter than traditional R1 (single braid) or R2 (double braid) hoses. R17 is designed for applications where space is limited but high-pressure performance is required, making it more flexible and easier to route in tight quarters compared to R1 or R2.

Q2: What materials are typically used in the construction of a wire braided hydraulic hose?

A2: A standard wire braided hydraulic hose consists of three main components: an inner tube (typically oil-resistant synthetic rubber like Nitrile Butadiene Rubber - NBR), one or more layers of high-tensile steel wire braid reinforcement, and an outer cover (usually abrasion, weather, and oil-resistant synthetic rubber such as SBR or EPDM blend).

Q3: How is the working pressure of a wire braided hydraulic hose determined?

A3: The working pressure is primarily determined by the strength and number of the steel wire reinforcement layers, the quality of the braiding process (e.g., braid angle), and the burst pressure of the hose. Manufacturers perform rigorous hydrostatic tests to determine the maximum safe working pressure, typically setting it at one-fourth of the average burst pressure (a 4:1 safety factor) to ensure a significant margin of safety during operation.

Q4: What are the critical factors to consider when selecting a wire braided hydraulic hose?

A4: The "STAMPED" acronym is a widely used guide: Size (Inner and Outer Diameter, Length), Temperature (Fluid and Ambient), Application (Environmental conditions, bending, abrasion), Media (Fluid compatibility), Pressure (Working and Burst), and Ends (Fittings and connections), Delivery (Time and location). Additionally, manufacturer reputation, certifications, and technical support are crucial.

Q5: What is the typical service life of a wire braided hydraulic hose, and how can it be extended?

A5: The service life varies greatly depending on the application severity, operating conditions (pressure cycles, temperature extremes, abrasion), and maintenance. While a typical lifespan can range from 2 to 5 years in demanding applications, some can last much longer. To extend life, ensure correct installation (avoid kinking, proper bend radius), regular inspection for wear/damage, using compatible fluids, and protecting against external abrasion and chemical exposure.

Q6: Are wire braided hydraulic hose products suitable for use with all types of hydraulic fluids?

A6: While our standard hoses, like the SAE 100 R17, are designed to be compatible with a wide range of petroleum-based hydraulic fluids, water-glycol, and water-oil emulsions, specific applications with non-standard or aggressive fluids may require specialized inner tube materials. Always verify fluid compatibility with the manufacturer to prevent premature degradation of the hose.

Q7: What is the importance of the smooth black cover on the SAE 100 R17 hose?

A7: The smooth black cover provides enhanced resistance to abrasion, ozone, and weather. Its smooth surface also reduces friction during installation in tight spaces and prevents accumulation of dirt or debris, which can be particularly advantageous in environments where cleanliness is important or where the hose may frequently rub against other components. This contributes significantly to the hose's overall durability and lifespan.

Conclusion: The Future of Fluid Power with Wire Braided Hydraulic Hose

The wire braided hydraulic hose, particularly advanced designs like the SAE 100 R17 Black Smooth Cover Hydraulic Hose, is more than just a component; it is a critical enabler of modern industrial progress. Its robust construction, superior pressure capabilities, and exceptional durability ensure the efficient and safe operation of hydraulic systems across a vast array of demanding applications.

As industries continue to evolve towards more compact, powerful, and automated machinery, the demand for high-performance, flexible, and resilient hydraulic hose solutions will only intensify. The intricate manufacturing processes, rigorous testing standards, and continuous innovation in materials science ensure that steel wire braided hydraulic hose remains at the forefront of fluid power transmission. By understanding its technical merits, application versatility, and the importance of partnering with a reputable manufacturer, businesses can unlock greater operational efficiency, reduce downtime, and achieve long-term cost savings. Investing in quality wire braided hydraulic hose is investing in the reliability and future performance of your most vital machinery.

References and Further Reading

- National Fluid Power Association (NFPA) Publications: https://www.nfpa.com/resources/Fluid-Power-Publications

- SAE International Standards for Fluid Conductors and Connectors: https://www.sae.org/standards/content/j517_202008/

- Hydraulics & Pneumatics Magazine Archives (Industry insights): https://www.hydraulicspneumatics.com/archive

- ISO 18752:2014 Rubber hoses and hose assemblies for hydraulic applications — Wire- or textile-reinforced types — Specification: https://www.iso.org/standard/60829.html

-

Premium Wire Braided Hydraulic Hose - Steel Reinforced for Durability

NewsAug.07,2025

-

Global Distribution PTFE Hose | Flexible & Steel-Braided

NewsAug.06,2025

-

Parker Teflon Hose Factories: AI-Enhanced Quality Solutions

NewsAug.04,2025

-

High-Performance Distribution PTFE Hose | Long Lifespan

NewsAug.03,2025

-

Premium Hydraulic Hose Wholesale | Bulk Savings & Durability

NewsAug.02,2025

-

Premium Chemical Resistant Distribution PTFE Hose

NewsAug.01,2025