335345435

Aug . 20, 2024 07:18 Back to list

Thermoplastic Hydraulic Hose Production and Manufacturing Solutions for Diverse Applications

The Advancements of Thermoplastic Hydraulic Hose Technology

In the ever-evolving world of industrial applications, thermoplastic hydraulic hoses have emerged as a vital component in various machinery and systems. The demand for efficient, durable, and lightweight solutions has spurred the development of specialized factories focused on the production of thermoplastic hydraulic hoses, catering to a wide array of sectors including construction, agriculture, and manufacturing.

What are Thermoplastic Hydraulic Hoses?

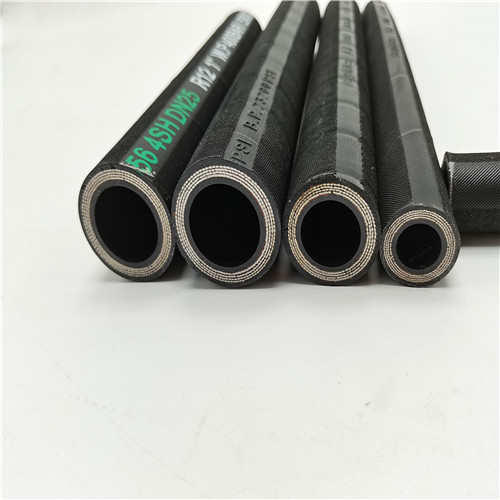

Thermoplastic hydraulic hoses are made from synthetic materials such as polyester or nylon, which are known for their resilience and lightweight properties. Unlike traditional rubber hydraulic hoses, thermoplastic variants offer advantages such as superior flexibility, resistance to abrasions, and a lower weight, making them ideal for applications requiring high performance in confined spaces. They are also resistant to a wide range of chemicals, oils, and temperatures, which enhances their functionality in harsh environments.

Manufacturing Process

The manufacturing process of thermoplastic hydraulic hoses involves several key steps. It begins with the selection of high-quality raw materials. The thermoplastic materials are carefully chosen based on their intended application, taking into consideration factors such as pressure ratings, temperature resistance, and compatibility with the hydraulic fluids they will carry.

Once the materials are selected, the extrusion process begins. This involves melting the thermoplastic resin and forcing it through a mold to create the hose shape. During this phase, it is also possible to integrate reinforcement materials such as steel or nylon braiding, which increases the hose’s strength and pressure tolerance. Following extrusion, the hose undergoes cooling and is cut to the desired lengths.

Quality control is a critical stage in the production process, where each hose is tested for pressure, flexibility, and overall durability. Various international standards, such as ISO and SAE certifications, play a significant role in ensuring that the hoses meet safety and performance requirements.

thermoplastic hydraulic hose factory

Applications and Benefits

Thermoplastic hydraulic hoses are used in a multitude of applications. In the construction industry, for instance, they are commonly employed in excavators, bulldozers, and other heavy machinery. Their lightweight structure allows for easier handling and maneuverability, enhancing operational efficiency. In agriculture, these hoses are used in spraying systems and irrigation equipment, ensuring reliability and consistent performance in demanding environments.

Manufacturers have also recognized the environmental benefits of thermoplastic hydraulic hoses. They are often recyclable, contributing to a reduction in waste compared to traditional rubber hoses. Furthermore, the lightweight nature of thermoplastic hoses can lead to lower fuel consumption in vehicles and machinery, offering significant cost savings in operations.

Future Trends

As technology advances, the future of thermoplastic hydraulic hoses looks promising. Innovations in material science are leading to the development of even more robust and versatile hoses. Smart hose technology, embedded with sensors to monitor pressure and temperature in real-time, is on the rise, paving the way for safer and more efficient systems.

In addition, the increasing focus on sustainability is driving factories to adopt eco-friendly practices in the production of thermoplastic hoses. Utilizing renewable materials and implementing energy-efficient manufacturing processes can significantly reduce the environmental footprint of these essential components.

Conclusion

In conclusion, the significance of thermoplastic hydraulic hoses in modern industrial applications cannot be overstated. As factories continue to innovate and improve their manufacturing processes, the versatility, efficiency, and sustainability of thermoplastic hoses will only increase, thereby ensuring their pivotal role in various sectors for years to come. With ongoing technological advancements, these hoses are set to meet the demands of tomorrow's industries, offering solutions that are both effective and eco-friendly.

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025