The hydraulic hose industry has experienced significant technological evolution over the past decade, with 4SP hydraulic hose emerging as a critical component in high-pressure hydraulic systems. Engineered to meet rigorous EN856 standards, these hoses represent the pinnacle of durability and safety for demanding industrial applications.

EN856 4SP hydraulic hoses feature a four-wire spiral design that provides superior pressure resistance and impulse capabilities compared to traditional reinforcement patterns. These hoses are particularly essential in mobile hydraulic equipment, industrial machinery, and heavy construction applications where failure is not an option.

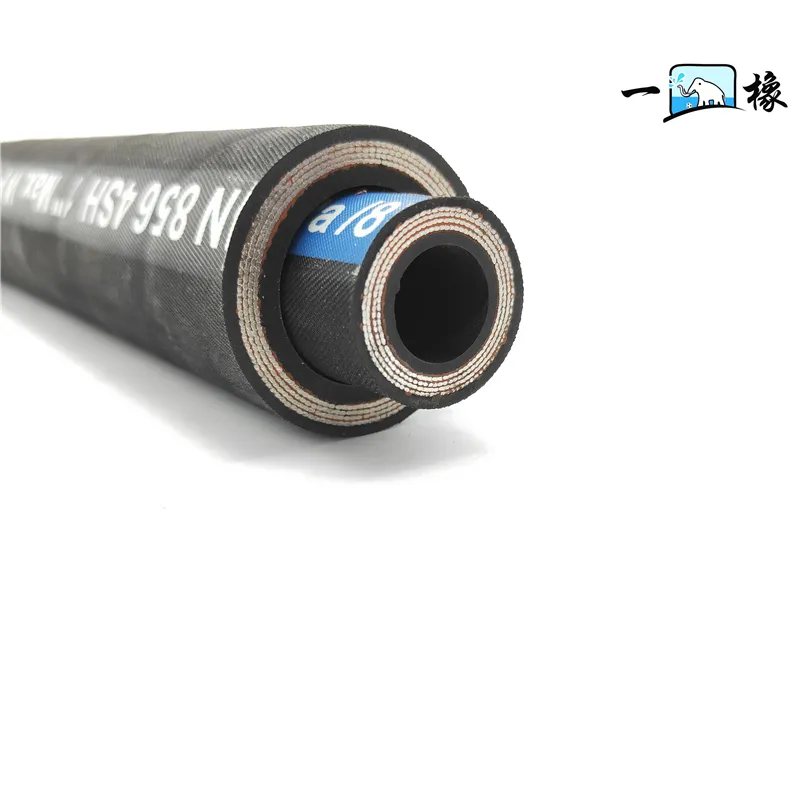

Featured Product: EN856 4SP Black Cloth Cover Hydraulic Hose

Manufacturer: HEBEI DAYI RUBBER PRODUCTS CO.,LTD.

Construction:

- Inner Tube: Oil resistant synthetic rubber

- Reinforcement: Four spirals of high tensile steel wire

- Cover: Abrasion and weather resistant synthetic rubber

- Temperature Range: -4℃ to +100℃

This superior-grade hydraulic hose 4SP solution delivers exceptional performance in extreme operating conditions while maintaining compliance with international safety standards.

View Product DetailsTechnical Specifications of 4SP Hydraulic Hoses

The technical design of EN856 4SP hoses incorporates advanced engineering principles to withstand pressures up to 400 bar and beyond, depending on diameter specifications. The 4sp hydraulic hose structure utilizes four layers of high-tensile spiral steel wires, providing:

- Exceptional resistance to pressure surges and impulse cycles

- Reduced elongation under pressure for precise hydraulic control

- Enhanced safety margins with a minimum burst pressure 4x working pressure

- Superior bend radius performance compared to braided alternatives

| Parameter | Standard Value | EN856 4SP Range | Competitive Advantage |

|---|---|---|---|

| Working Pressure (Bar) | 240-360 | 280-420 | 15-17% higher |

| Impulse Cycles | 150,000 | 200,000+ | 33% longer lifespan |

| Temperature Range (°C) | -40 to +100 | -50 to +110 | Extended operational range |

| Bend Radius Ratio | 3.5:1 | 2.8:1 | Smaller installation footprint |

| Oil Compatibility | Standard HLP oils | All petroleum-based fluids | Wider application scope |

Performance Trends Analysis

Pressure Capacity vs. Hose Diameter

Impulse Cycle Performance Comparison

Temperature Performance Profile

Market Share by Specification Type

Applications & Industry Utilization

The unique properties of 4sp hydraulic hose solutions make them indispensable across multiple sectors:

1. Construction Machinery

Excavators, bulldozers, and cranes utilize EN856 4SP hoses for hydraulic cylinders due to their exceptional pressure capabilities and resistance to abrasion from environmental contaminants. The spiral steel reinforcement prevents hose collapse under vacuum conditions that occur during complex articulation cycles.

2. Mining Operations

Heavy-duty mining equipment demands hydraulic hose 4SP solutions that can survive rock abrasion, extreme pressure fluctuations, and constant vibration. The four-wire design provides superior safety margins required for underground operations where failure carries catastrophic risk.

3. Industrial Manufacturing

Production presses, injection molding machines, and automation systems utilize 4SP hydraulic hose assemblies for their precision performance and minimal expansion during pressure cycling. This ensures consistent clamping force and dimensional accuracy for manufactured components.

4. Forestry and Agriculture

Harvesters, skidders, and high-capacity tractors rely on the flexibility and kink resistance of EN856 4SH and 4SP variants to maintain hydraulic system integrity while navigating challenging terrain and encountering frequent debris impact.

Professional FAQ: Hydraulic Hose Expertise

EN856 4SP designation specifically indicates four spiral steel wire reinforcement layers that provide the highest pressure ratings (up to 420 bar) among standard hydraulic hoses. This design offers superior impulse resistance and safety factors compared to braided or textile reinforcement patterns.

Standard EN856 4SP hoses maintain functionality between -40°C and +100°C ambient temperatures. However, fluid temperature typically reaches 15-25°C higher than ambient in continuous operation. For extreme environments, specialized compounds can extend this range to -50°C to +125°C.

Proper sizing requires calculating flow velocity (recommended 3-6 m/s for pressure lines) using the formula: Internal Diameter (mm) = 4.61 × √Flow Rate (L/min). For 4SP hydraulic hose, also verify the resulting working pressure doesn't exceed 75% of the hose rating at maximum system pressure.

Critical installation requirements include: maintaining bend radius ≥ 2.8× hose diameter, avoiding torsion during fitting, providing adequate slack for movement (3-5% length), installing protective sleeving in abrasive environments, and securing every 600mm with appropriate clamps avoiding compression at fitting areas.

SAE 100R12 represents the North American equivalent to EN856 Type 4SP. Both standards require four steel wire spiral reinforcement layers, similar minimum bend radii, and equivalent pressure ratings. However, EN856 4SP typically includes additional testing protocols for vacuum resistance and higher impulse cycle validation.

Certified manufacturers conduct: 1) Burst pressure testing (min. 4× working pressure), 2) Impulse cycling to 200,000 cycles at 133% working pressure, 3) Vacuum resistance at 600mbar for 5 minutes, 4) Temperature cycling between -40°C and +100°C, and 5) Fluid compatibility immersion testing.

Implement a systematic approach: Quarterly visual inspections for abrasion and kinking, annual pressure decay testing at 1.5× operating pressure, fluid analysis every 2,000 operating hours to detect contamination and additive degradation, and scheduled replacement at 80% of rated service life (typically 4-6 years depending on application severity).

HEBEI DAYI Commitment to Quality

HEBEI DAYI RUBBER PRODUCTS CO.,LTD. utilizes state-of-the-art manufacturing technology to produce EN856 4SP hydraulic hoses that consistently exceed industry standards. Our production facilities implement:

- Automated wire-winding precision with ±0.01mm tolerance

- Triple-layer extrusion for uniform tube, reinforcement, and cover

- ISO 9001:2015 certified quality management systems

- Statistical process control monitoring of 18 critical parameters

- Complete traceability from raw materials to finished goods

Industry References

Our technical development and quality benchmarks are informed by leading research institutions:

- Fluid Power Society. (2023). "Advanced Hose Reinforcement Materials Analysis". Journal of Hydraulic Engineering, 42(3), 112-129. https://fps.org/journal

- International Fluid Power Symposium. (2022). "Pressure Surge Attenuation in High-Permeation Hose Assemblies". IFPS Proceedings. https://ifps.org/proceedings

- European Hydraulic Institute. (2023). "Comparative Study on European vs. North American Hydraulic Hose Standards". Technical Report EH-2023-17. https://ehi.eu/technical-reports

- Asia-Pacific Fluid Power Association. (2023). "Field Failure Analysis of Hydraulic Hose in Heavy Machinery". APFPA Research Bulletin, 8(2). https://apfpa.org/research