335345435

Sep . 29, 2024 21:59 Back to list

PTFE Steel-Braided Hose Manufacturers and Their Production Processes Explained

The Importance of PTFE Steel-Braided Hoses in Various Industries

Polytetrafluoroethylene (PTFE) steel-braided hoses are increasingly becoming essential components in numerous industrial applications due to their outstanding performance characteristics and durability. This article aims to provide an overview of PTFE steel-braided hoses, their manufacturing process, benefits, and applications across various fields.

What is PTFE?

PTFE, commonly known as Teflon, is a high-performance fluoropolymer known for its exceptional chemical resistance and low friction properties. It can withstand high temperatures, making it suitable for a variety of demanding applications. When it comes to hoses, the incorporation of a steel braid provides additional strength and protection, making them robust enough for high-pressure environments.

Manufacturing Process

The production of PTFE steel-braided hoses involves several stages. Initially, the PTFE material is extruded into a tubular form. This raw PTFE tube is then reinforced with a steel braid that enhances pressure resistance and prevents kinking. The braiding process typically involves precision machinery that intertwines the steel wires around the PTFE tube, ensuring a tight and secure fit.

Post-braiding, the assembly undergoes tests to check for leaks and other quality control measures. The final product is often subjected to a series of performance evaluations, including pressure tests and temperature tolerance assessments. The result is a reliable and resilient hose that can operate in extreme conditions.

Advantages of PTFE Steel-Braided Hoses

1. Chemical Resistance One of the most significant benefits of PTFE hoses is their ability to resist corrosion and degradation from various chemicals, including acids, bases, and solvents. This makes them ideal for use in chemical processing industries where exposure to harsh substances is common.

ptfe steel-braided hose factories

2. High-Temperature Tolerance PTFE can handle temperatures up to 500°F (260°C), allowing these hoses to be used in high-temperature applications. This property is particularly useful in the aerospace and automotive industries.

3. Flexibility and Durability The combination of PTFE and steel braid provides a hose that is both flexible and sturdy. Users can maneuver the hose into tight spaces without worrying about kinking, and the steel braid ensures that the hose can withstand high pressures without bursting.

4. Low Friction PTFE's low friction characteristics enable smooth fluid flow, reducing the risk of pressure drops and improving the efficiency of fluid transfer systems.

5. Long Lifespan These hoses are designed to last, often outperforming other types of hoses in terms of durability and resistance to wear and tear.

Applications Across Industries

PTFE steel-braided hoses find applications in several industries

- Chemical Processing Used for transferring acids and other hazardous materials safely. - Aerospace Ideal for fuel and hydraulic systems due to their high-temperature and pressure resistance. - Automotive Used in fuel lines, brake lines, and hydraulic systems for added safety and reliability. - Pharmaceuticals Important for applications requiring sanitary conditions and resistance to corrosive sterilants.

Conclusion

In summary, PTFE steel-braided hoses are a critical part of the modern industrial landscape. Their superior chemical resistance, ability to handle extreme temperatures, and robust construction make them suitable for a broad range of applications, ensuring safety and efficiency across various sectors. As industries continue to evolve and demand higher performance materials, PTFE steel-braided hoses will undoubtedly play a key role in meeting these challenges. Investing in quality PTFE hoses from reputable manufacturers can be a game changer for businesses looking to enhance their operational effectiveness.

-

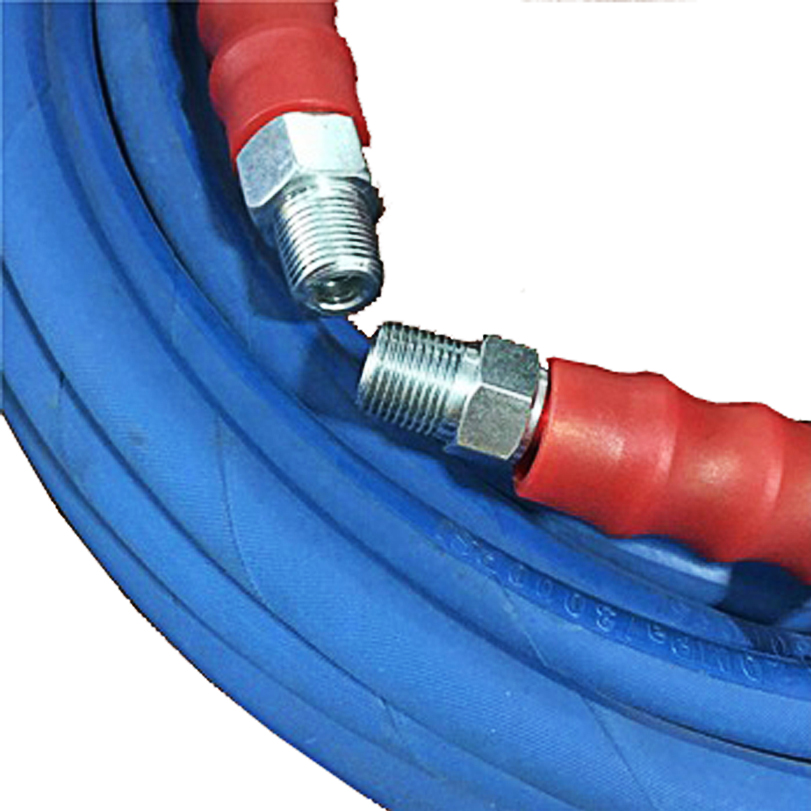

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025