335345435

Nov . 13, 2024 19:50 Back to list

ptfe flexible hose

The Versatility and Benefits of PTFE Flexible Hoses

Polytetrafluoroethylene (PTFE) flexible hoses are emerging as a popular choice in various industrial applications due to their unique properties and versatility. Known for their superb chemical resistance and flexibility, PTFE hoses are increasingly replacing traditional rubber and metal hoses across many sectors, including pharmaceuticals, food and beverage, chemical processing, and more. This article delves into the characteristics, advantages, and applications of PTFE flexible hoses.

Understanding PTFE

PTFE, commonly recognized by the brand name Teflon, is a synthetic polymer that features a distinctive molecular structure. This structure gives PTFE its remarkable properties, including a high temperature tolerance, excellent chemical resistance, and low friction coefficient. These features make PTFE an ideal material for manufacturing flexible hoses that can accommodate the rigorous demands of various industries.

Key Characteristics of PTFE Flexible Hoses

1. Chemical Resistance One of the standout features of PTFE hoses is their exceptional resistance to a wide range of chemicals, including strong acids, bases, and organic solvents. This makes them suitable for handling abrasive and corrosive substances without degradation or the risk of leaks.

2. Temperature Tolerance PTFE can withstand temperatures ranging from -200°C to +260°C (-328°F to +500°F). This broad temperature range ensures that PTFE hoses can be used in extreme environments without losing their structural integrity or performance.

3. Flexibility and Ease of Handling Unlike rigid metal hoses, PTFE flexible hoses can be easily manipulated and bent, allowing for efficient routing in tight spaces. This flexibility makes installation simpler and enables better access to machinery and equipment.

4. Low Friction PTFE has a low friction coefficient, which results in reduced wear and tear and improved flow characteristics. This property is particularly important in applications involving sensitive fluids and gases, where flow efficiency is crucial.

5. Non-Stick Surface Due to its non-stick property, PTFE hoses are easy to clean, reducing downtime and maintenance costs while ensuring sanitary conditions in food and pharmaceutical applications.

ptfe flexible hose

Applications of PTFE Flexible Hoses

Given their impressive properties, PTFE flexible hoses find applications across a broad spectrum of industries

1. Pharmaceuticals In the pharmaceutical industry, the integrity and purity of the substances being transported are paramount. PTFE hoses help maintain product quality by preventing contamination and ensuring smooth flow without reaction with the conveyed materials.

2. Food and Beverage The food industry demands high hygiene standards and resilience to various cleaning agents. PTFE hoses are FDA-approved and can withstand high-temperature cleaning processes, making them ideal for transporting food and beverage products.

3. Chemical Processing Chemically aggressive environments are commonplace in various manufacturing processes. PTFE flexible hoses can handle hazardous materials, including acids and alkalis, without risk to safety or integrity.

4. Aerospace and Automotive PTFE hoses are increasingly employed in aerospace and automotive applications for conveying fluids, thanks to their lightweight nature and durability. They help reduce overall weight, which can lead to improved fuel efficiency.

5. Oil and Gas In the oil and gas industry, PTFE hoses are used for transferring petroleum products and other fluids, offering protection against corrosion and degradation from harsh chemicals and high pressures.

Conclusion

PTFE flexible hoses are an essential component in modern industrial applications due to their unique attributes. Their resistance to chemicals, ability to withstand extreme temperatures, and flexibility make them the perfect substitute for traditional hose materials. As industries continue to innovate and seek more efficient solutions, the demand for PTFE hoses is set to rise. Transitioning to PTFE solutions can enhance safety, performance, and product quality across various sectors, underscoring the growing significance of these versatile hoses in today's industrial landscape.

In summary, investing in PTFE flexible hoses is not just about improving operational efficiency; it is also about ensuring safety and reliability in the handling of critical materials across numerous applications.

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025

-

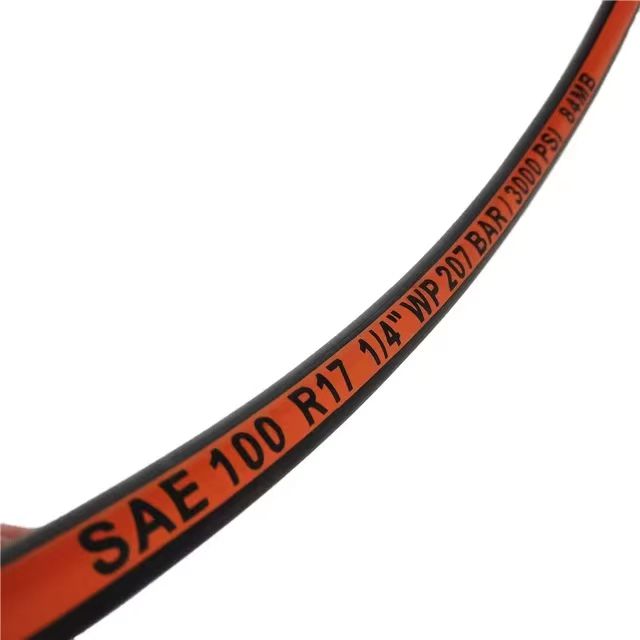

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025