335345435

Jun . 12, 2024 17:59 Back to list

Produce SAE100R8 thermoplastic hoses for OEMs

Exploring the World of OEM Thermoplastic Hose Manufacturers for SAE 100R8

In the realm of industrial fluid conveyance systems, the role of high-quality hoses is paramount. One specific type that has gained significant traction in recent years is the SAE 100R8 thermoplastic hose. This innovative product, designed and manufactured by Original Equipment Manufacturers (OEMs), offers a blend of durability, flexibility, and performance, making it an ideal choice for various applications.

SAE 100R8 hoses are primarily engineered from thermoplastic materials, which exhibit exceptional resistance to heat, abrasion, and chemical exposure. These properties are particularly crucial in industries like automotive, aerospace, and manufacturing, where harsh operating conditions are common. The 'R8' classification, as per the Society of Automotive Engineers (SAE) standards, denotes a minimum four-spiral construction for enhanced pressure resistance and flexibility.

OEM thermoplastic hose manufacturers are at the forefront of this technology, constantly pushing the boundaries of design and production. They invest heavily in research and development to create hoses that not only meet but exceed industry standards. Their focus lies in delivering products with consistent quality, reliability, and efficiency, tailored to the unique requirements of their clients.

Manufacturing processes for SAE 100R8 hoses involve a meticulous combination of extrusion, braiding, and vulcanization. The thermoplastic compound is extruded to form the inner tube, which is then reinforced with multiple layers of spirally wound synthetic fibers. This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress

This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress oem thermoplastic hose sae100r8 manufacturers.

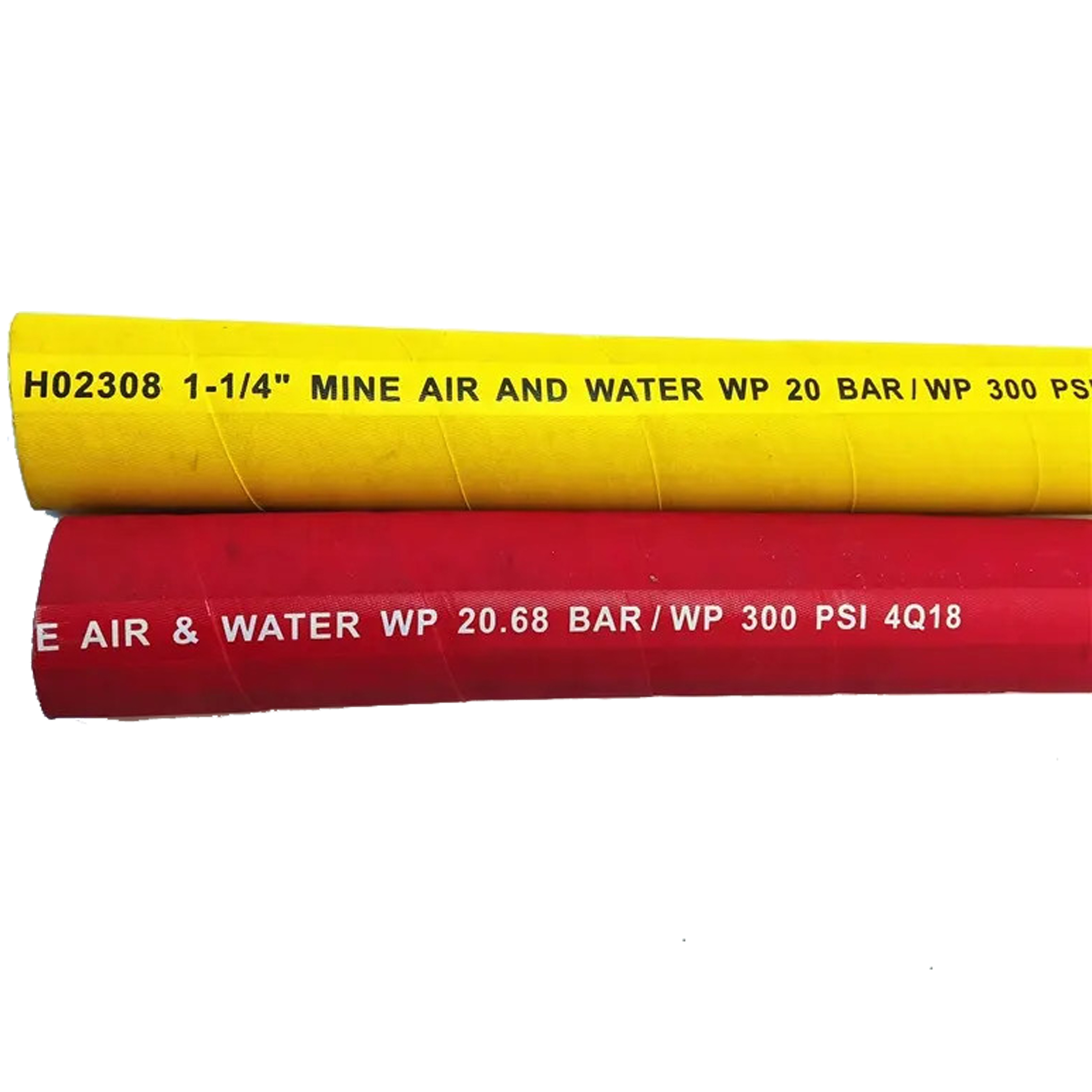

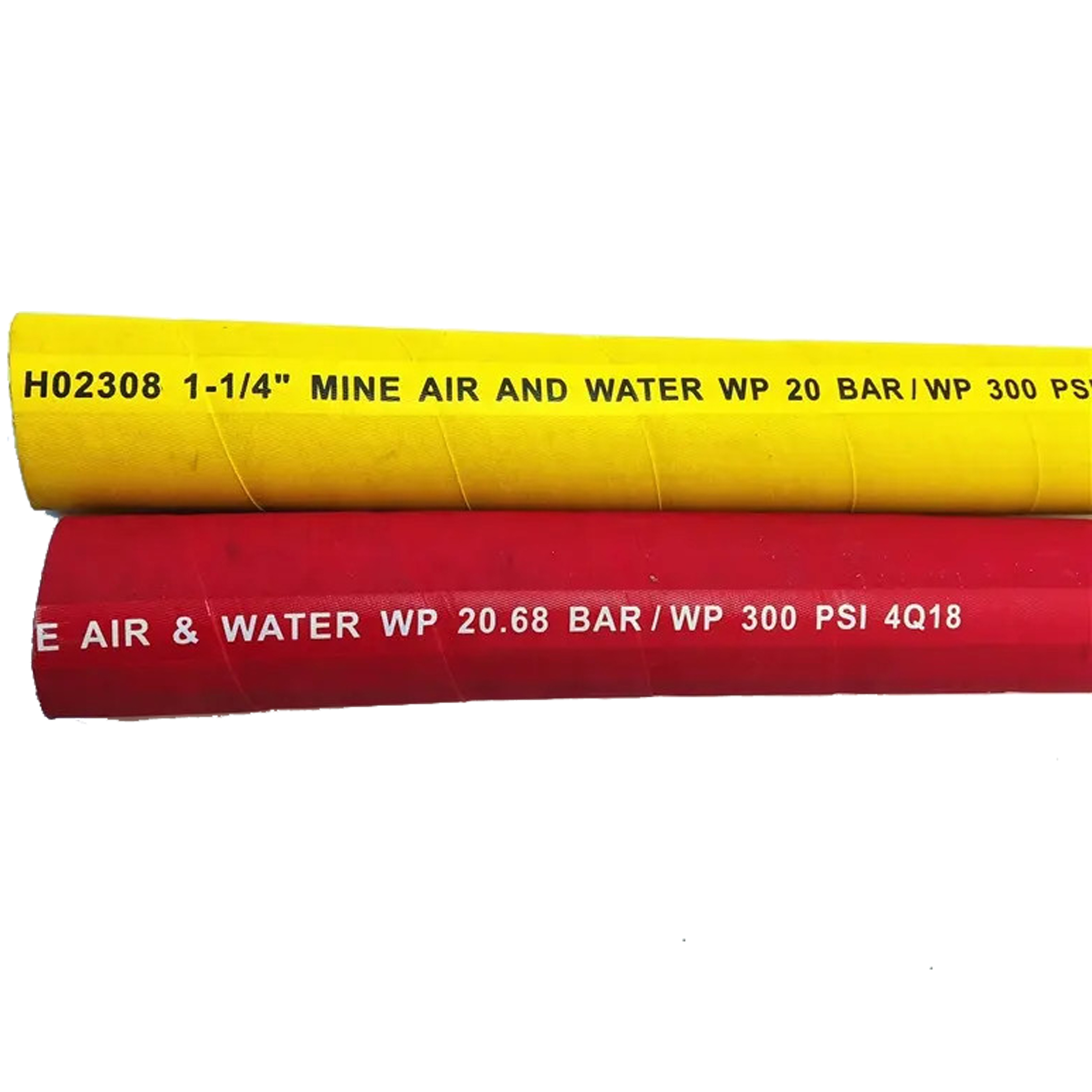

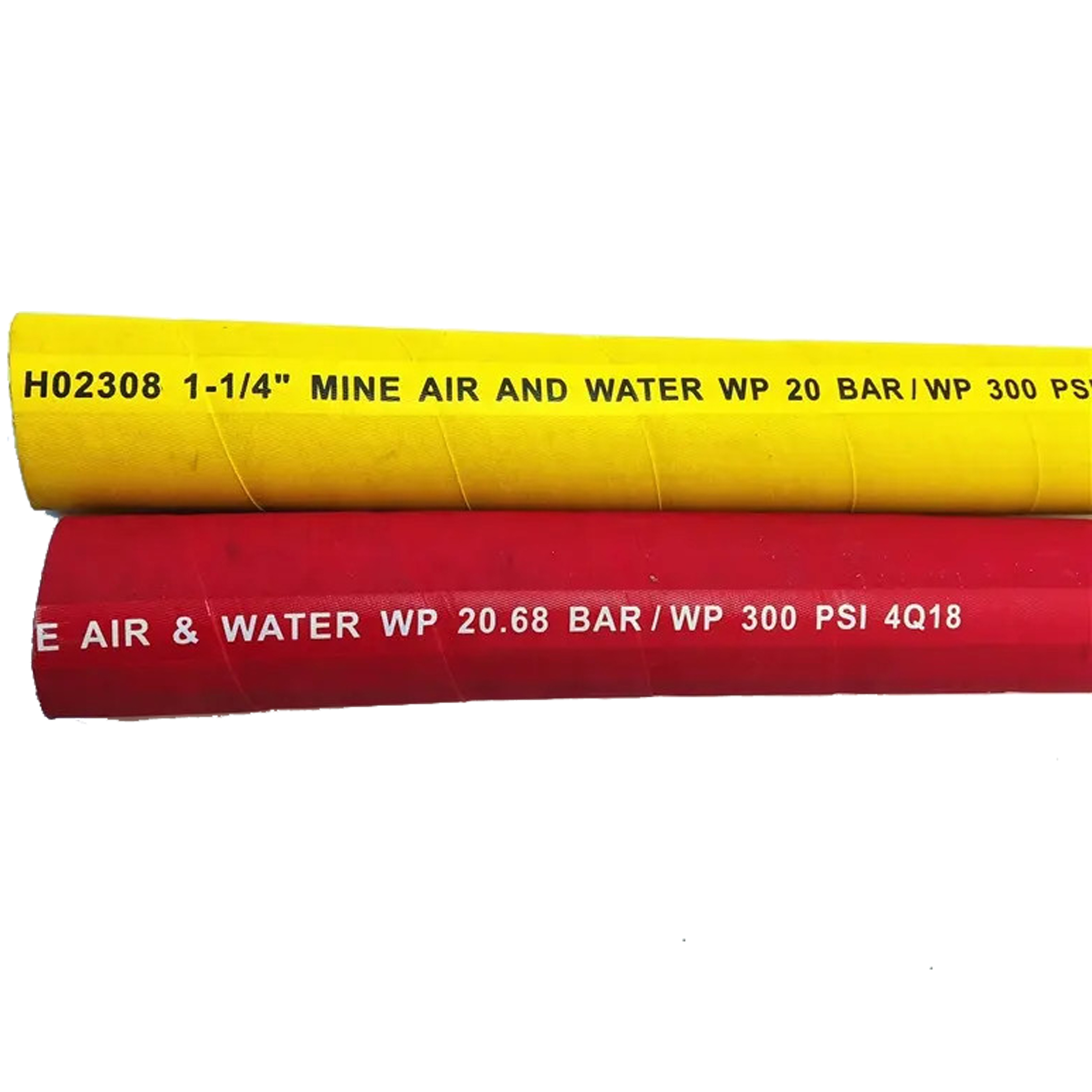

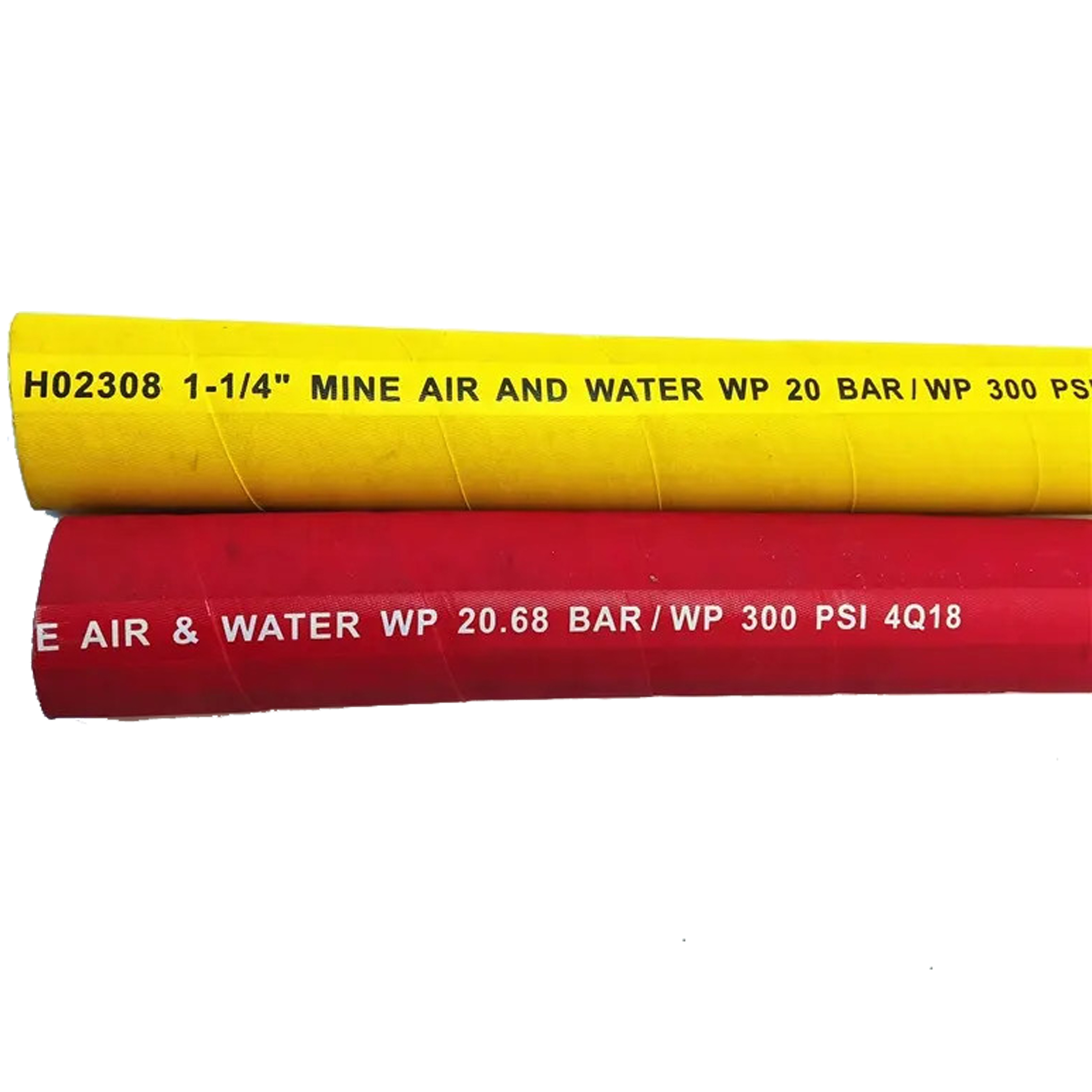

One key advantage of choosing an OEM manufacturer for SAE 100R8 thermoplastic hoses is their customization capabilities. They can offer hoses in various sizes, pressure ratings, and colors, often with custom fittings and ends to ensure seamless integration into existing systems. Moreover, these manufacturers often provide comprehensive technical support, including material selection advice, installation guidelines, and maintenance tips.

The commitment of OEM thermoplastic hose manufacturers to sustainability is also noteworthy. Many of them use recyclable materials and implement eco-friendly production methods, contributing to a greener future. Furthermore, the lightweight and compact nature of SAE 100R8 hoses reduces transportation and storage costs, aligning with the principles of lean manufacturing.

In conclusion, the world of OEM thermoplastic hose manufacturers for SAE 100R8 is a dynamic and evolving sector. These manufacturers, through their expertise and innovation, are shaping the future of fluid conveyance solutions. Their products not only enhance operational efficiency but also contribute to environmental sustainability, making them a reliable partner for businesses seeking top-notch hydraulic hose technology. As the demand for robust and adaptable hoses continues to grow, the significance of these manufacturers in meeting these demands cannot be overstated.

oem thermoplastic hose sae100r8 manufacturers.

One key advantage of choosing an OEM manufacturer for SAE 100R8 thermoplastic hoses is their customization capabilities. They can offer hoses in various sizes, pressure ratings, and colors, often with custom fittings and ends to ensure seamless integration into existing systems. Moreover, these manufacturers often provide comprehensive technical support, including material selection advice, installation guidelines, and maintenance tips.

The commitment of OEM thermoplastic hose manufacturers to sustainability is also noteworthy. Many of them use recyclable materials and implement eco-friendly production methods, contributing to a greener future. Furthermore, the lightweight and compact nature of SAE 100R8 hoses reduces transportation and storage costs, aligning with the principles of lean manufacturing.

In conclusion, the world of OEM thermoplastic hose manufacturers for SAE 100R8 is a dynamic and evolving sector. These manufacturers, through their expertise and innovation, are shaping the future of fluid conveyance solutions. Their products not only enhance operational efficiency but also contribute to environmental sustainability, making them a reliable partner for businesses seeking top-notch hydraulic hose technology. As the demand for robust and adaptable hoses continues to grow, the significance of these manufacturers in meeting these demands cannot be overstated.

This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress

This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress This is followed by an outer cover, usually made from the same or similar thermoplastic material, providing additional protection against environmental factors and mechanical stress oem thermoplastic hose sae100r8 manufacturers.

One key advantage of choosing an OEM manufacturer for SAE 100R8 thermoplastic hoses is their customization capabilities. They can offer hoses in various sizes, pressure ratings, and colors, often with custom fittings and ends to ensure seamless integration into existing systems. Moreover, these manufacturers often provide comprehensive technical support, including material selection advice, installation guidelines, and maintenance tips.

The commitment of OEM thermoplastic hose manufacturers to sustainability is also noteworthy. Many of them use recyclable materials and implement eco-friendly production methods, contributing to a greener future. Furthermore, the lightweight and compact nature of SAE 100R8 hoses reduces transportation and storage costs, aligning with the principles of lean manufacturing.

In conclusion, the world of OEM thermoplastic hose manufacturers for SAE 100R8 is a dynamic and evolving sector. These manufacturers, through their expertise and innovation, are shaping the future of fluid conveyance solutions. Their products not only enhance operational efficiency but also contribute to environmental sustainability, making them a reliable partner for businesses seeking top-notch hydraulic hose technology. As the demand for robust and adaptable hoses continues to grow, the significance of these manufacturers in meeting these demands cannot be overstated.

oem thermoplastic hose sae100r8 manufacturers.

One key advantage of choosing an OEM manufacturer for SAE 100R8 thermoplastic hoses is their customization capabilities. They can offer hoses in various sizes, pressure ratings, and colors, often with custom fittings and ends to ensure seamless integration into existing systems. Moreover, these manufacturers often provide comprehensive technical support, including material selection advice, installation guidelines, and maintenance tips.

The commitment of OEM thermoplastic hose manufacturers to sustainability is also noteworthy. Many of them use recyclable materials and implement eco-friendly production methods, contributing to a greener future. Furthermore, the lightweight and compact nature of SAE 100R8 hoses reduces transportation and storage costs, aligning with the principles of lean manufacturing.

In conclusion, the world of OEM thermoplastic hose manufacturers for SAE 100R8 is a dynamic and evolving sector. These manufacturers, through their expertise and innovation, are shaping the future of fluid conveyance solutions. Their products not only enhance operational efficiency but also contribute to environmental sustainability, making them a reliable partner for businesses seeking top-notch hydraulic hose technology. As the demand for robust and adaptable hoses continues to grow, the significance of these manufacturers in meeting these demands cannot be overstated. Share

Latest news

-

High-Quality Distribution PTFE Hose for Industrial Applications

NewsJul.25,2025

-

High-Precision Hydraulic Hose Crimping Machine for Fast, Reliable Fittings

NewsJul.24,2025

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025