335345435

Jul . 25, 2025 01:01 Back to list

High-Quality Distribution PTFE Hose for Industrial Applications

1. Understanding Distribution PTFE Hose in Modern Industrial Systems

The increasing global demand for high-performance fluid transfer solutions has ushered in the rapid adoption of distribution PTFE hose technology. As a critical component in energy, automotive, chemical, pharmaceutical, and aerospace applications, PTFE flex hose delivers unrivaled flexibility, chemical resistance, and safety under extreme conditions. At HEBEI DAYI RUBBER PRODUCTS CO.,LTD., we empower clients worldwide with state-of-the-art distribution ptfe hose solutions that comply with stringent international standards.

2. Industry Trends: Why Flexible PTFE Hose Leads Fluid Transfer Innovation

- Sustainability & Lifespan: PTFE (Polytetrafluoroethylene) hoses offer a lifespan exceeding most rubber hoses due to superior resistance to corrosion and high temperatures (Hydraulics & Pneumatics Forum).

- Safety Compliance: With growing attention on workplace safety, the adoption of ptfe flexible hose pipe with SAE, DIN, and ISO certifications is increasing rapidly.

- Hybrid Construction: Combining PTFE teflon hose with stainless or steel-braided reinforcements maximizes both flexibility and pressure endurance (SAE Technical Paper).

- Application Diversification: Used across sectors like pharmaceuticals, automotive hydraulics, high-purity chemical transfer, offshore drilling, aviation fuel lines, and advanced robotics.

- Customization & Smart Manufacturing: Smart manufacturing enhances production ptfe hose processes, leading to adaptable product lines that meet niche industrial demands.

3. Technological Parameters: Distribution PTFE Hose Data Table

| Parameter | Details | Industry Standard/Typical Value | Application Relevance |

|---|---|---|---|

| Material | PTFE (Polytetrafluoroethylene) | Virgin/Convoluted/Corrugated | Chemical Resistance, Food-Grade Suitability |

| Temperature Range | -70℃ ~ +260℃ | -60℃~+250℃ / Up to 260℃ | Extreme Service (Cryogenic to High Heat) |

| Pressure Rating | 65 – 420 bar | Depends on size/braiding | High-Pressure Hydraulics |

| Inner Diameter (ID) | 3mm - 51mm | 6mm, 8mm, 12mm typical | Application Flexibility |

| Reinforcement | Stainless Steel Braid / Synthetic Fiber | Single or Double Braid | Durability, Burst Resistance |

| Outer Cover | Fiber, Stainless, Thermoplastic Nylon | Thermoplastic, Rubber, or SS Braided | Environmental Protection |

| Conductivity Level | Antistatic/Static Dissipative | ASTM D257, DIN EN 16643 | Safety for Flammable Fluids |

| Standard Certification | SAE 100R14, FDA, ISO 9001 | FDA, ISO, NSF | Food, Pharma, Safety Applications |

4. PTFE Flexible Hose Pipe & Allied Products Line-up

PTFE flexible hoses, known for their extreme temperature endurance and exceptional chemical resistance, are available in an extensive range at HEBEI DAYI RUBBER PRODUCTS CO.,LTD.. For professionals seeking reliable PTFE stainless braided hose or state-of-the-art PTFE hydraulic hose for advanced fluid transfer, our product spectrum leads the global market.

Featured Product:

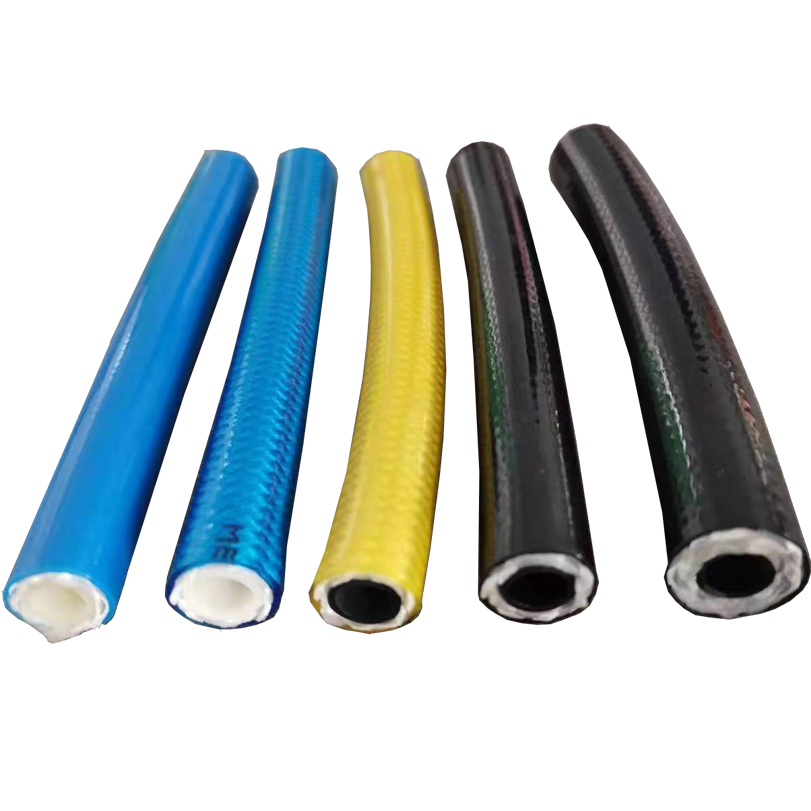

R8 High Pressure Synthetic Fibre Braid Resin Hose

Featured Product: R8 High Pressure Synthetic Fibre Braid Resin Hose

- Structure: Inner Tube (Nylon), Reinforcement (High Pressure Synthetic Fiber), Cover (High Flexibility Nylon or Thermoplastic).

- Key Capabilities: Lightweight, high flexibility, fine anti-chemical & impulse performance, low pressure loss, smooth bore.

- Application Fields: Automobile, Engineering Machinery, Lathes, Mining, Oil Paint Spurting, Aviation & Spaceflight, Cooling, Hydraulic Control Systems.

- View full product technical details & request a quote

Key Technical Specification Table: R8 High Pressure Synthetic Fibre Braid Resin Hose

| Parameter | Specification | Feature |

|---|---|---|

| Inner Tube | Nylon | Smooth, Chemical-Resistant |

| Reinforcement | High Pressure Synthetic Fibre Braid | Impulse-Resistant, Flexible |

| Outer Cover | High Flexibility Nylon/Thermoplastic | Durable, Wear-Resistant |

| Working Pressure | Up to 415 Bar (6,000 PSI) | High-Pressure Hydraulic Performance |

| Inner Diameter Range | 3mm – 14mm | Adaptable for Multiple Use-Cases |

| Temperature Range | -40℃ ~ +100℃ | Wide Thermal Applicability |

5. Technologies Empowering PTFE Flex Hose Performance

- Advanced Braiding (Stainless & Synthetic): High-tensile braids improve burst pressure and flexural life, as demonstrated by ptfe steel-braided hose structures.

- Homogeneous Wall Thickness: Ensures uniform flow, minimizing turbulence and enabling energy savings.

- Precision-Engineered End Fittings: Compatible with SAE/ISO/EN standards; supports quick couplers, swage fittings for high-reliability assembly.

- PTFE Teflon Hose Customization: Tapered & convoluted inner tubes for ultra-flexibility; thermoplastic covers for enhanced external wear.

- Antistatic PTFE: Protects against static discharge in hazardous environments (Pumps and Systems Journal).

- Robotic Process Automation: Ensures consistent production ptfe hose quality and traceability.

6. Applications of Distribution PTFE Hose in Major Industries

The exceptional characteristics of PTFE flexible hose pipe have enabled its widespread adoption in diverse industrial niche markets:

- Hydraulic Control Systems: PTFE hydraulic hose for precise pressure delivery and chemical compatibility.

- Aviation & Spaceflight: Lightweight distribution PTFE hose solutions for hydraulic and fuel systems.

- Oil & Gas: Used in aggressive environment piping where safety and durability are paramount.

- Automotive: Fuel, brake, air-conditioning, and power-steering lines rely on ptfe teflon hose for reliability and longevity.

- Pharmaceutical & Food: PTFE stainless braided hose complies with FDA & EU regulations for sanitary transfers.

- Mining/Engineering: Adapted for high-pressure water, miner coolant, corrosive slurry, or mechanical lubrication systems.

7. EEAT & Authoritativeness: Standardization and Global Benchmarks

As a leading OEM/ODM distribution ptfe hose manufacturer, HEBEI DAYI RUBBER PRODUCTS CO.,LTD. adheres to the latest SAE, EN, and ISO standards to guarantee product reliability and global compatibility.

- Certifications: ISO 9001:2015 certified; products comply with SAE 100R14, EN 16643, FDA, and REACH.

- References: SAE J343 - Hose Testing Standard, ScienceDirect: PTFE Hose Innovations

- Industry Forums/FAQ: Contributions and technical FAQ at Hydraulics & Pneumatics, Eng-Tips PTFE Hose Forum

8. Professional FAQ: PTFE Hose Selection and Application Terminology

Q1: What are the key advantages of using a distribution PTFE hose over conventional rubber hoses?

A: PTFE hoses provide outstanding chemical resistance, wider temperature range (-70°C to +260°C), greater life expectancy, and non-ageing performance. They are superior in high-pressure, high-purity, and hazardous liquid applications. (Reference)

Q2: What is the difference between a PTFE stainless braided hose and a synthetic fibre braided hose?

A: Stainless braided hoses offer higher pressure ratings, enhanced durability, and improved heat resistance. Synthetic fiber braided hoses are lighter, more flexible, and cost-efficient, ideal where extreme pressure is not required.

Q3: In what scenarios should I specify a PTFE hydraulic hose?

A: Choose PTFE hydraulic hoses for demanding applications involving aggressive fluids, high system pressures, or environments with rapid temperature fluctuations. They are perfect for critical automotive, mining, or spaceflight hydraulics.

Q4: What certifications are essential for PTFE flex hose in the food or pharmaceutical industry?

A: Look for FDA, USDA, or EU EC 1935/2004 certifications, along with ISO 9001. These ensure non-contamination and hygiene compliance as discussed in relevant FDA documentation (FDA Industry Guide).

Q5: Can PTFE flexible hose pipe be used in cold as well as hot environments?

A: Yes, thanks to its unique molecular structure, PTFE remains flexible from -70°C up to +260°C, making it perfect for cryogenics and high-heat environments.

Q6: How do I select end fittings for a distribution PTFE hose?

A: End fitting selection is governed by pressure, fluid type, environment, and regulatory requirement (SAE, ISO, EN standards). Always confirm fitting material compatibility for your fluid/process.

Q7: What testing is performed to validate the safety of a PTFE teflon hose?

A: Key tests include burst pressure, impulse/fatigue cycle, vacuum and leak tests, chemical resistance, and dimensional stability per SAE J343, ISO 1402, and customer specifications.

9. SEO Optimization: Why Choose HEBEI DAYI RUBBER PRODUCTS CO.,LTD. for Your Flexible PTFE Hose Solutions?

- Complete PTFE Range: PTFE flex hose, production ptfe hose, ptfe flexible hose pipe, and large-bore, steel-braided assemblies.

- Tailor-Made Capabilities: Advanced engineering to match technical drawings or on-site measurements, with a full spectrum of material and fitting options.

- Global Logistics: Direct shipment to all regions; export compliance and robust after-sales service.

- Expertise & Trust: Decades of industry experience, continuous R&D investment, and highly specialized engineering teams.

- Resource Center: Continuous education and live chat support via our website for all distribution ptfe hose technical queries.

Get your quote or technical support today.

Visit: HEBEI DAYI RUBBER PRODUCTS CO.,LTD.

Or email: info@dayihose.com

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.26,2025

-

High-Quality Distribution PTFE Hose for Industrial Applications

NewsJul.25,2025

-

High-Precision Hydraulic Hose Crimping Machine for Fast, Reliable Fittings

NewsJul.24,2025

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025