335345435

Nov . 09, 2024 15:31 Back to list

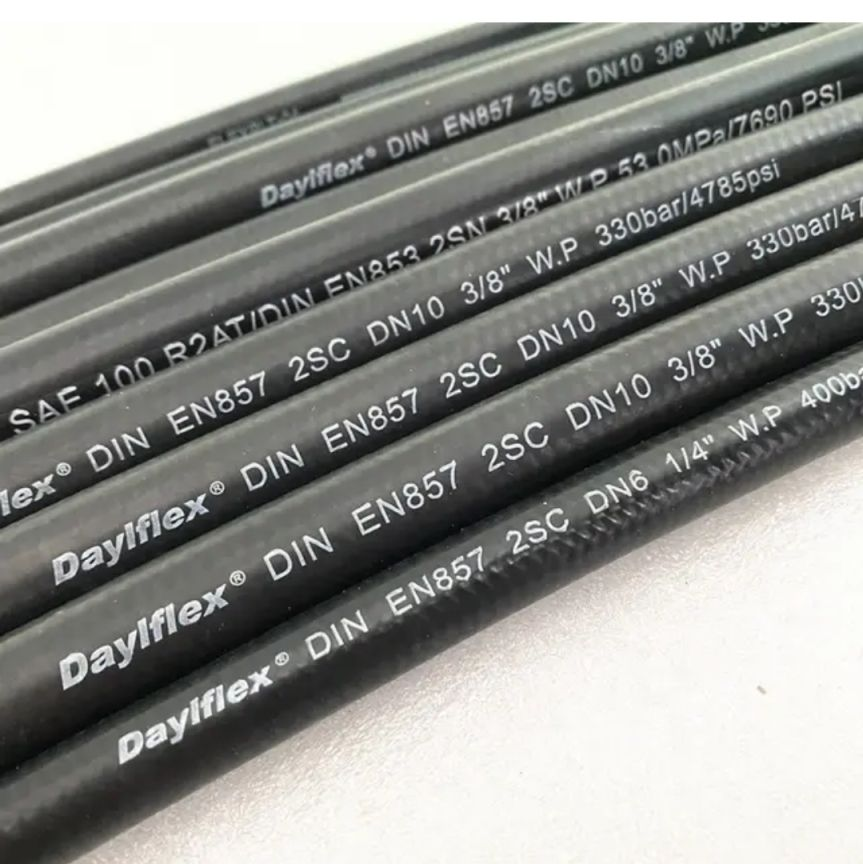

Custom Four Wire Spiral Hydraulic Hose Manufacturers for High-Pressure Applications

The Importance of OEM Four Wire Spiral Hydraulic Hoses in Industrial Applications

In the world of hydraulic systems, the components used play a crucial role in determining the efficiency, safety, and longevity of machinery. One such essential component is the hydraulic hose. Among various types of hydraulic hoses available, the OEM four wire spiral hydraulic hose stands out for its superior performance and durability. This article will delve into the features, benefits, and applications of these hoses while highlighting their significance in industrial settings.

What is an OEM Four Wire Spiral Hydraulic Hose?

The term OEM refers to Original Equipment Manufacturer, indicating that these hoses are built to meet the exact specifications and requirements of original equipment. Four wire spiral hydraulic hoses are constructed with four layers of steel wire spiraled around the hose, providing exceptional strength and flexibility. This design makes them capable of handling high-pressure applications, typically up to 4000 psi, making them indispensable in heavy-duty industries such as construction, mining, and manufacturing.

Key Features

1. High Pressure Capacity The most significant advantage of the four wire spiral design is its resistance to high pressure. With the ability to handle high bursts of pressure, these hoses are ideal for more demanding applications where safety and reliability are paramount.

2. Flexibility and Durability The construction of these hoses makes them highly flexible, allowing for easier routing in complex machinery layouts. Moreover, the steel wire reinforcements ensure that the hoses are not only resistant to internal pressure but also to external impacts and abrasions, making them suitable for tough working conditions.

3. Temperature Resistance OEM four wire spiral hydraulic hoses are designed to withstand extreme temperatures, which is essential for equipment that operates in harsh environments. They can typically handle temperatures ranging from -40°C to +100°C.

4. Corrosion and Abrasion Resistance The outer cover of these hoses is often made from materials that are resistant to oil, chemicals, and UV rays, thereby prolonging the hose's service life and reducing maintenance costs over time.

Benefits of Using OEM Four Wire Spiral Hydraulic Hoses

Utilizing OEM quality hydraulic hoses offers several benefits

- Safety With high-pressure capabilities and robust construction, these hoses reduce the risk of failures, leaks, and potential accidents, ensuring a safer work environment.

oem four wire spiral hydraulic hose factories

- Cost-Effectiveness Although the initial cost might be higher, the durability and lower failure rates contribute to lower overall maintenance costs. Investing in high-quality hoses can lead to less frequent replacements and reduced downtime.

- Custom Solutions OEM manufacturers can tailor hydraulic hoses to fit specific applications and machinery needs, ensuring compatibility and optimal performance.

- Enhanced Performance The reliability and strength of these hoses allow for improved operational performance, leading to increased productivity and efficiency within industrial processes.

Applications

OEM four wire spiral hydraulic hoses find their use in various industries where high pressure and heavy loads are common. Some of the primary applications include

- Construction Machinery Excavators, bulldozers, and cranes heavily rely on these hoses for their hydraulic systems, ensuring they operate efficiently under demanding conditions.

- Mining Industry In operations where machinery is subjected to severe abrasion and heavy loads, these hoses provide the necessary strength and durability.

- Agricultural Equipment Tractors and harvesters utilize four wire spiral hoses to ensure reliable hydraulic fluid delivery for various functions.

- Manufacturing In production lines where hydraulic machines are in constant operation, these hoses maintain performance and avoid disruptions.

Conclusion

The role of OEM four wire spiral hydraulic hoses in industrial applications cannot be overstated. Their robust construction, high-pressure capabilities, and adaptability make them essential components in numerous machines and systems. By choosing high-quality hoses from reputable manufacturers, industries can ensure safety, efficiency, and longevity in their hydraulic systems, ultimately leading to more productive and cost-effective operations. Whether in construction, mining, agriculture, or manufacturing, these hoses are integral to the functionality of heavy machinery, solidifying their place as a cornerstone in the hydraulic equipment landscape.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025