335345435

Nov . 04, 2024 22:53 Back to list

oem en854 3te

Understanding OEM EN854 3TE Applications and Features

In the world of industrial manufacturing and equipment, the importance of choosing the right materials cannot be understated. Among these materials, hoses have a crucial role, especially in specific applications such as hydraulic systems, pneumatic systems, and general industrial machinery. One prominent standard in the realm of hoses is the EN854 3TE specification, often used by Original Equipment Manufacturers (OEMs) for various applications. This article explores the significance, features, and applications of EN854 3TE hoses while highlighting their vital role in ensuring operational efficiency.

What is OEM EN854 3TE?

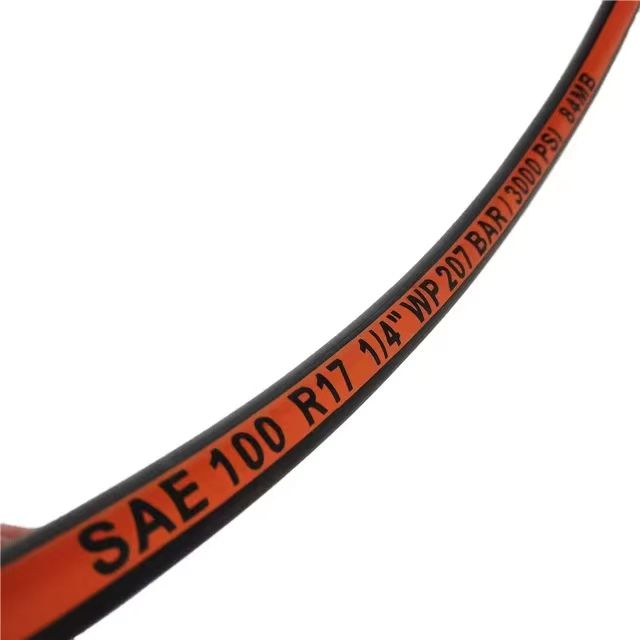

The EN854 standard pertains to the construction and performance characteristics of textile-reinforced hydraulic hoses. The 3TE designation denotes a specific type of hose that features three spirals of textile reinforcement and a rubber cover. The hoses are designed to convey hydraulic fluids under pressure, making them essential for a variety of hydraulic applications in industries such as construction, agriculture, and automotive manufacturing.

The OEM in OEM EN854 3TE indicates that these hoses are commonly utilized by Original Equipment Manufacturers, who incorporate them into their machinery and equipment designs. As OEMs are responsible for ensuring the reliability and performance of their products, the choice of hoses conforming to the EN854 standard is crucial.

Key Features of EN854 3TE Hoses

1. High Pressure Resistance EN854 3TE hoses are engineered to withstand high pressures, making them suitable for high-demand applications. They can typically handle pressures ranging from 10 to 25 bar, depending on the specific design.

2. Superior Flexibility One of the standout features of these hoses is their flexibility. This characteristic allows them to be routed through tight spaces in machinery without compromising their functionality.

oem en854 3te

3. Resistant to Abrasion and Weather The rubber cover of EN854 3TE hoses provides excellent resistance against abrasion, UV exposure, and ozone, extending the longevity of the hoses even in harsh environments.

4. Large Temperature Range These hoses maintain their performance across a wide temperature range, typically from -40°C to +100°C, making them suitable for both extreme hot and cold conditions.

5. Versatile Applications The versatility of EN854 3TE hoses allows them to be used in a multitude of industries, including but not limited to, agriculture (for tractors and harvesters), construction machinery (excavators and cranes), and transportation industries (for hydraulic systems in vehicles).

Applications of EN854 3TE Hoses

The applications of OEM EN854 3TE hoses are vast and varied. In the agricultural sector, they are extensively utilized in tractors and combine harvesters for hydraulic lifting and steering mechanisms. In construction, these hoses are integral to the operation of cranes and excavators, enabling the fluid power systems to function efficiently. Additionally, in automotive applications, they are widely used for braking systems, ensuring safety and reliability while driving.

Conclusion

The OEM EN854 3TE hoses stand out as a reliable solution for hydraulic and pneumatic applications across numerous industries. Their robust construction, outstanding flexibility, and resistance to environmental factors ensure that equipment operates smoothly and efficiently. Understanding the properties and features of these hoses is essential for manufacturers and engineers when designing and selecting components for their machinery, ultimately contributing to enhanced productivity and safety in operations. Choosing the right hoses means investing in the reliability of equipment, making EN854 3TE a crucial component in hydraulic systems worldwide.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025