335345435

Jan . 14, 2025 15:29 Back to list

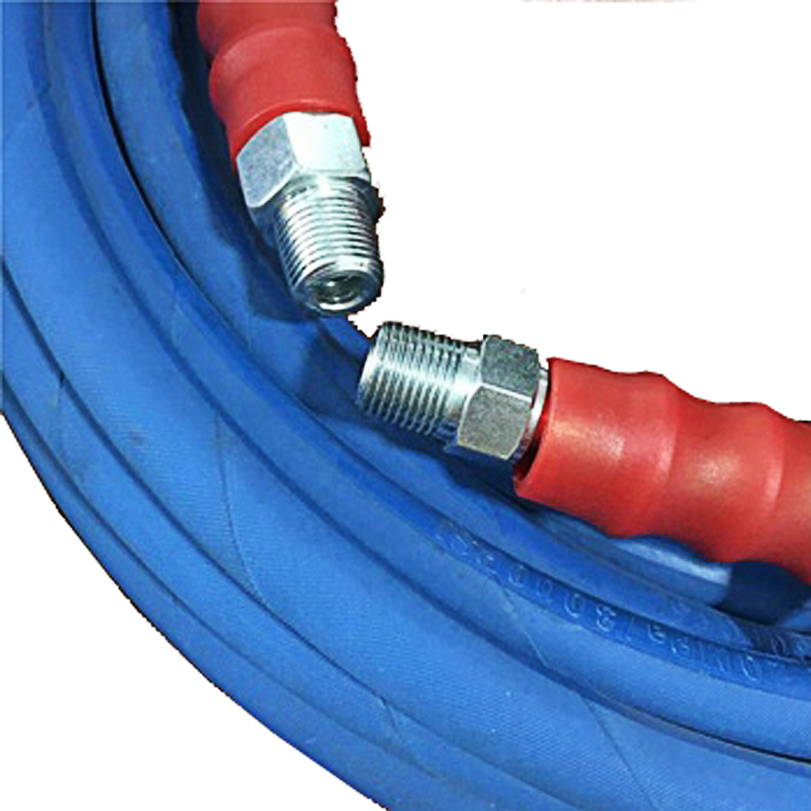

EN856 4SP Black smooth Cover Hydraulic Hose

Hydraulic hose fittings are critical to numerous industrial and mechanical systems, serving as the conduits through which hydraulic fluids transfer energy. Understanding the types and applications of these fittings enhances system performance and ensures safety. As an expert in hydraulic technology, let’s delve into the various types of hydraulic hose fittings and their significance in industry-specific applications.

Material selection is equally critical in determining a fitting's suitability. Often constructed from brass, stainless steel, or carbon steel, each material has specific properties that make it appropriate for certain environments. For instance, stainless steel fittings are highly resistant to corrosion, making them ideal for offshore and chemical processing industries. Brass fittings, known for their conductivity and ease of machining, are commonly used in applications involving air and water. The thread type also plays a significant role in the compatibility and seal strength of hydraulic hose fittings. Common thread types include NPT (National Pipe Thread), BSP (British Standard Pipe), and metric threads. Each has distinct characteristics and applications. NPT threads, prevalent in North American applications, provide a tapered seal that enhances with pressure, making them suitable for high-pressure connections. BSP threads are widely used internationally and offer parallel or tapered options depending on the need for a direct or leak-tight joint. Metric threads are specified when uniformity with international equipment is necessary. Proper installation and maintenance of hydraulic hose fittings literally save lives. Incorrect fitting selection can lead to leaks, pressure drops, or catastrophic failure under pressure, causing downtime and potential injury. Thus, consulting with hydraulic specialists during the design phase ensures fittings are selected and installed to industry standards, contributing to the overall trustworthiness and authoritativeness of the installation. In conclusion, hydraulic hose fittings are not merely mechanical components; they are fundamental to the system's integrity and performance. Recognizing the specific needs of the application, the pressures involved, and environmental conditions is crucial in the selection process. Expertise and guidance from industry professionals not only optimize system performance but also instill confidence and ensure lasting operational success. This comprehensive understanding of hydraulic fittings underlines their significance and safeguards the system’s output, efficiency, and longevity in demanding applications.

Material selection is equally critical in determining a fitting's suitability. Often constructed from brass, stainless steel, or carbon steel, each material has specific properties that make it appropriate for certain environments. For instance, stainless steel fittings are highly resistant to corrosion, making them ideal for offshore and chemical processing industries. Brass fittings, known for their conductivity and ease of machining, are commonly used in applications involving air and water. The thread type also plays a significant role in the compatibility and seal strength of hydraulic hose fittings. Common thread types include NPT (National Pipe Thread), BSP (British Standard Pipe), and metric threads. Each has distinct characteristics and applications. NPT threads, prevalent in North American applications, provide a tapered seal that enhances with pressure, making them suitable for high-pressure connections. BSP threads are widely used internationally and offer parallel or tapered options depending on the need for a direct or leak-tight joint. Metric threads are specified when uniformity with international equipment is necessary. Proper installation and maintenance of hydraulic hose fittings literally save lives. Incorrect fitting selection can lead to leaks, pressure drops, or catastrophic failure under pressure, causing downtime and potential injury. Thus, consulting with hydraulic specialists during the design phase ensures fittings are selected and installed to industry standards, contributing to the overall trustworthiness and authoritativeness of the installation. In conclusion, hydraulic hose fittings are not merely mechanical components; they are fundamental to the system's integrity and performance. Recognizing the specific needs of the application, the pressures involved, and environmental conditions is crucial in the selection process. Expertise and guidance from industry professionals not only optimize system performance but also instill confidence and ensure lasting operational success. This comprehensive understanding of hydraulic fittings underlines their significance and safeguards the system’s output, efficiency, and longevity in demanding applications.

Share

Latest news

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025

-

Premium 38mm Hydraulic Hose Factories | Direct & Reliable

NewsAug.08,2025

-

Premium Wire Braided Hydraulic Hose - Steel Reinforced for Durability

NewsAug.07,2025