335345435

Oct . 22, 2024 04:26 Back to list

High-Quality Hydraulic Hose Production for Durable Fluid Transfer Solutions

Understanding the Hydraulic Hose Factory A Hub of Engineering Excellence

In the world of engineering and industrial applications, hydraulic hoses play a critical role in transmitting fluid power efficiently and safely. A hydraulic hose factory is a specialized manufacturing unit dedicated to producing these vital components that are essential in various machinery and vehicles. This article will explore the significance, processes, and innovations within a hydraulic hose factory.

Importance of Hydraulic Hoses

Hydraulic hoses are designed to handle high-pressure environments where liquid is used to transmit force. They are employed in numerous applications, ranging from construction machinery like excavators and bulldozers to agricultural equipment and automobiles. The durability and reliability of hydraulic hoses ensure that these machines operate effectively, making them indispensable in industries such as construction, mining, automotive, and manufacturing.

The Manufacturing Process

The production of hydraulic hoses involves several key steps, each requiring precision and expertise to ensure high-quality outcomes. The typical manufacturing process begins with the selection of raw materials. High-strength synthetic rubber and reinforced materials are often chosen for their resilience and ability to withstand intense pressure and harsh environmental conditions.

1. Material Preparation The raw materials, including rubber and textile or steel reinforcement, are prepared and cut to specified lengths. This is where the foundational strength of the hose is established.

2. Hose Extrusion The rubber is then extruded into the desired shape to form a tube. This step requires advanced machinery that can maintain consistent thickness and diameter, critical for pressure containment.

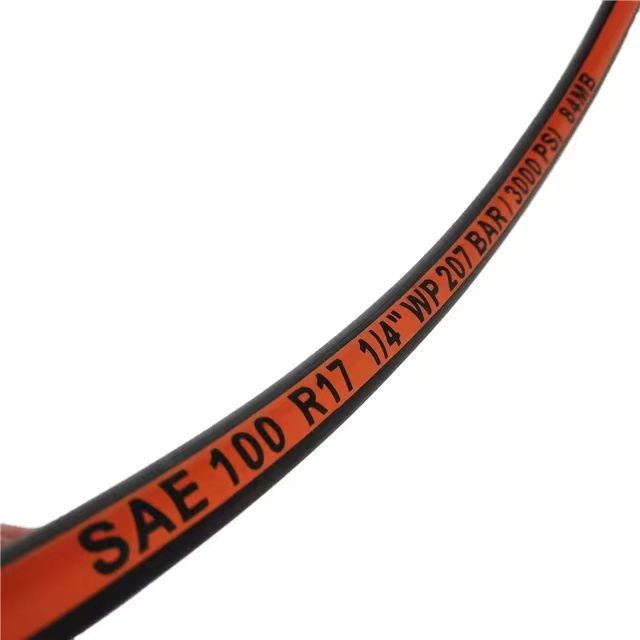

3. Reinforcement Addition After the base tube is formed, layers of reinforcement are added. This can be achieved through wrapping steel wire or braiding textile fibers around the rubber tube. The choice of reinforcement depends on the required pressure rating and application of the hose.

hydraulic hose factory

4. Curing The assembled hose is then subjected to a curing process, commonly known as vulcanization. This step involves heating the hose in an oven, which cross-links the rubber molecules, enhancing the physical and chemical properties of the hose, such as elasticity and heat resistance.

5. Testing Once the hoses are cured, rigorous testing is conducted to ensure they meet industry standards. Tests include leak testing, burst pressure testing, and flexibility assessments. Quality control is paramount, as even minor defects can lead to catastrophic failures in high-pressure applications.

6. Final Assembly After passing quality assurance tests, hydraulic hoses are assembled with fittings and connectors based on customer specifications. This step is crucial as it determines how the hose will interface with other components in a hydraulic system.

Innovations in Hydraulic Hose Manufacturing

The hydraulic hose industry is continuously evolving, driven by advancements in technology and growing demands for safer, more efficient products. One significant innovation is the development of hoses that are more resistant to abrasion, heat, and chemicals, thereby extending their lifespan and reducing maintenance costs.

Moreover, the adoption of automation and robotics in manufacturing processes has improved efficiency and precision. Automated systems can oversee the production line, ensuring consistent quality and reducing human error. The use of computer-aided design (CAD) software in the design phase allows for customized hose solutions, catering to specific industry needs.

Conclusion

A hydraulic hose factory is much more than just a production facility; it serves as a cornerstone for industries reliant on hydraulic power. By understanding the manufacturing processes and innovations within these facilities, we can appreciate the engineering excellence that goes into producing hydraulic hoses. As technology advances, these factories will continue to play a vital role in meeting the ever-increasing demands of various sectors, driving efficiency and safety in industrial applications.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025