335345435

Jun . 26, 2024 03:00 Back to list

Hydraulic Rubber Hose Manufacturers Factories and Plants Overview

The Evolution and Significance of Hydraulic Rubber Hose Factories

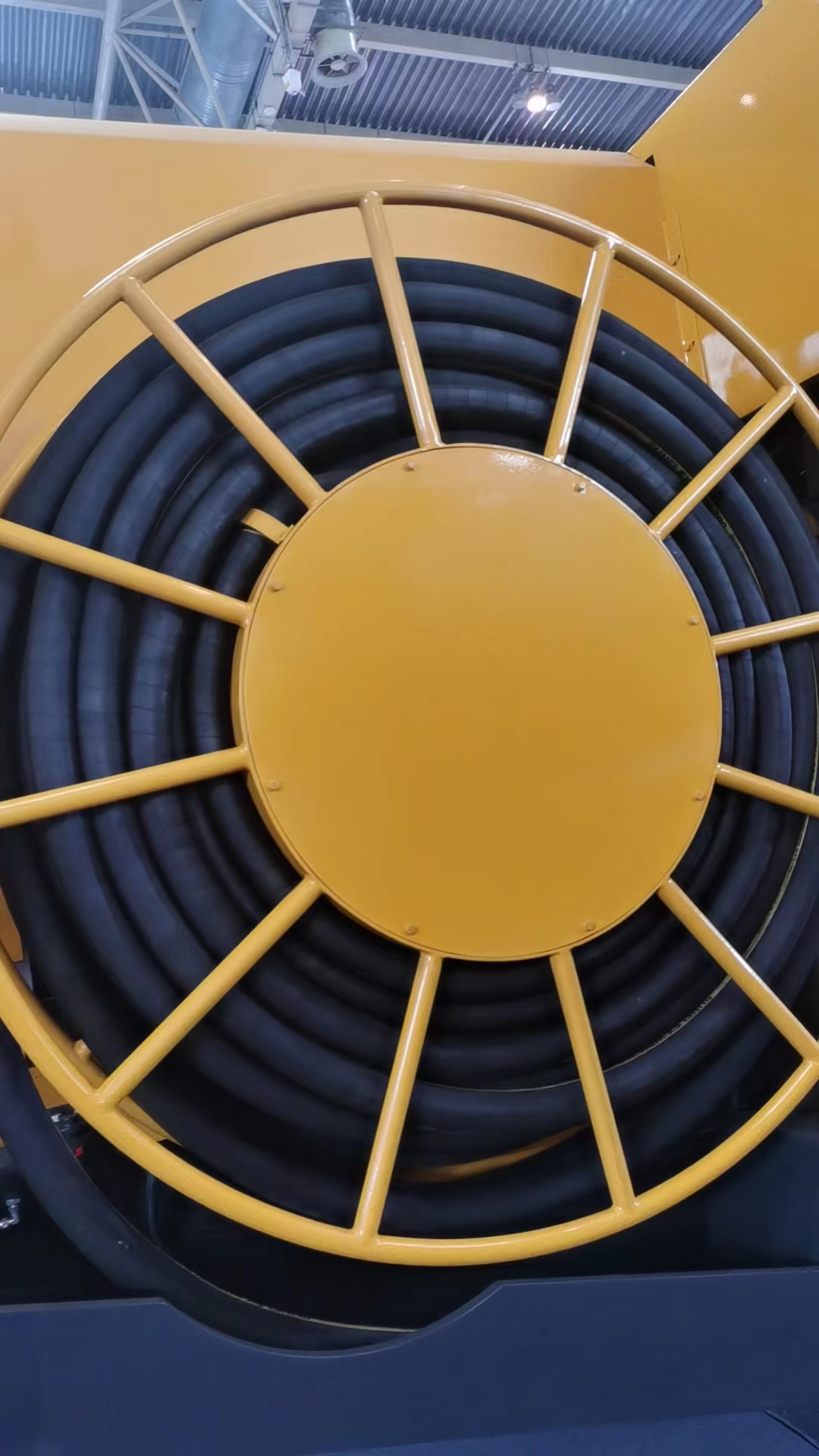

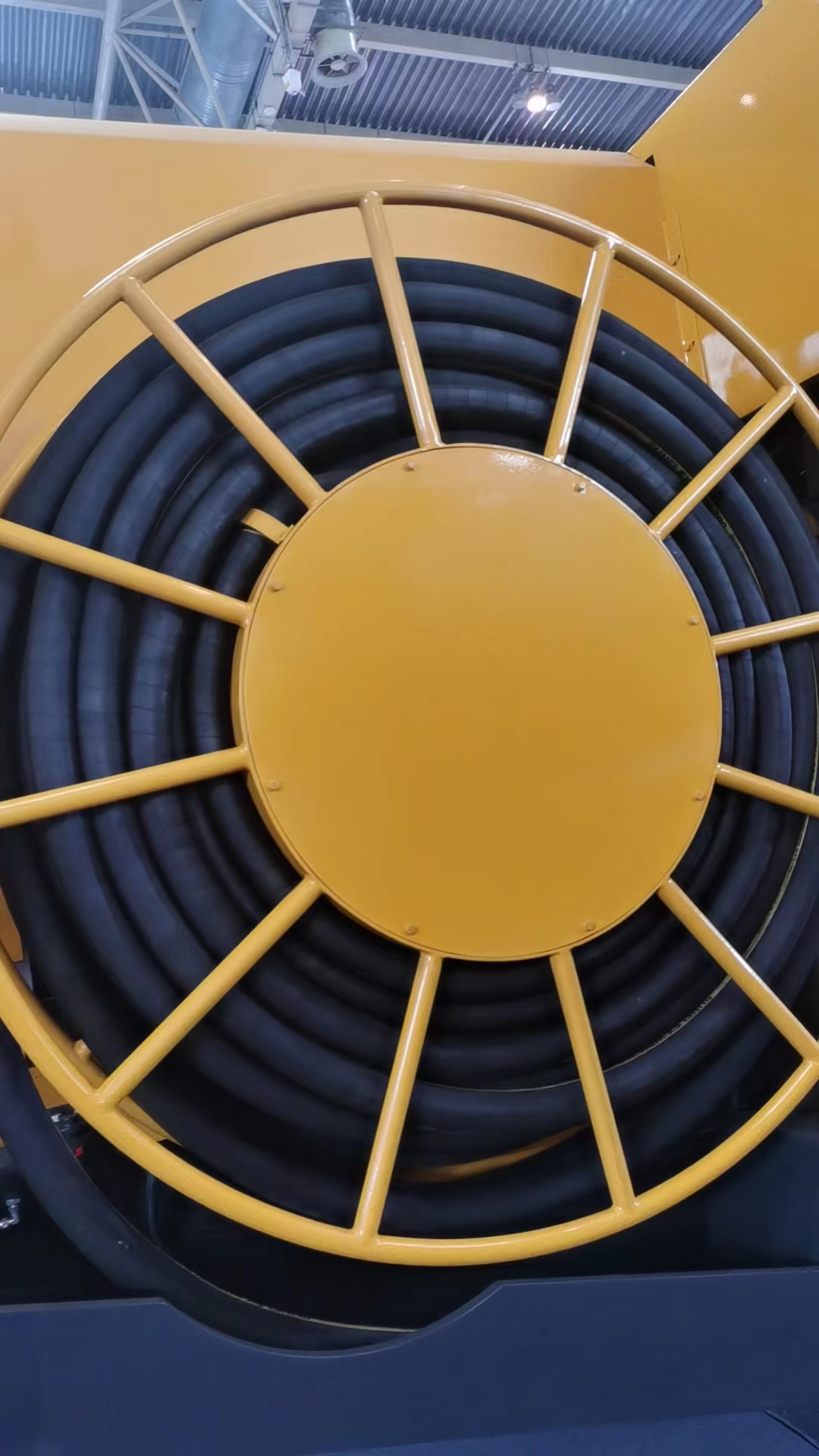

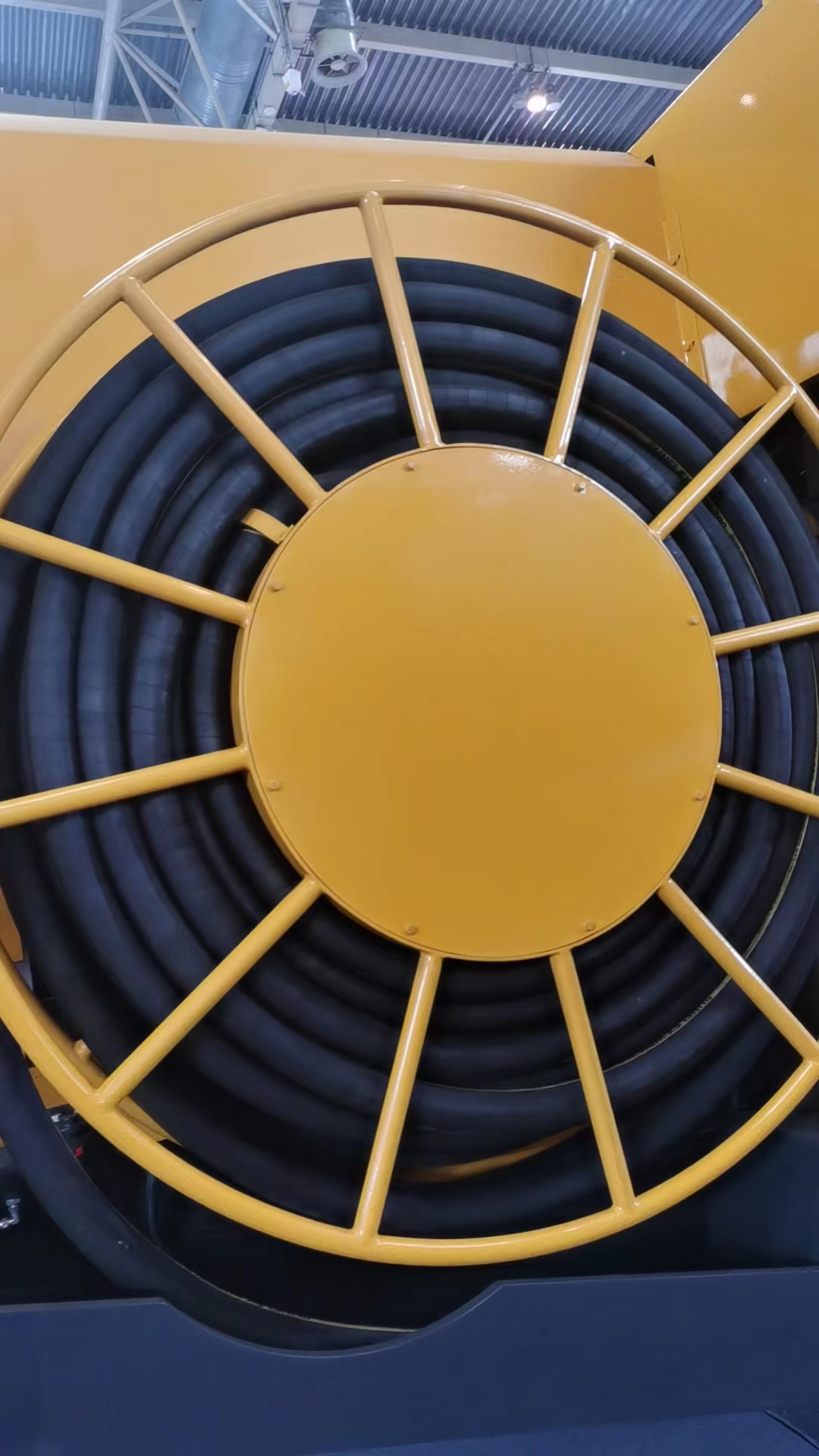

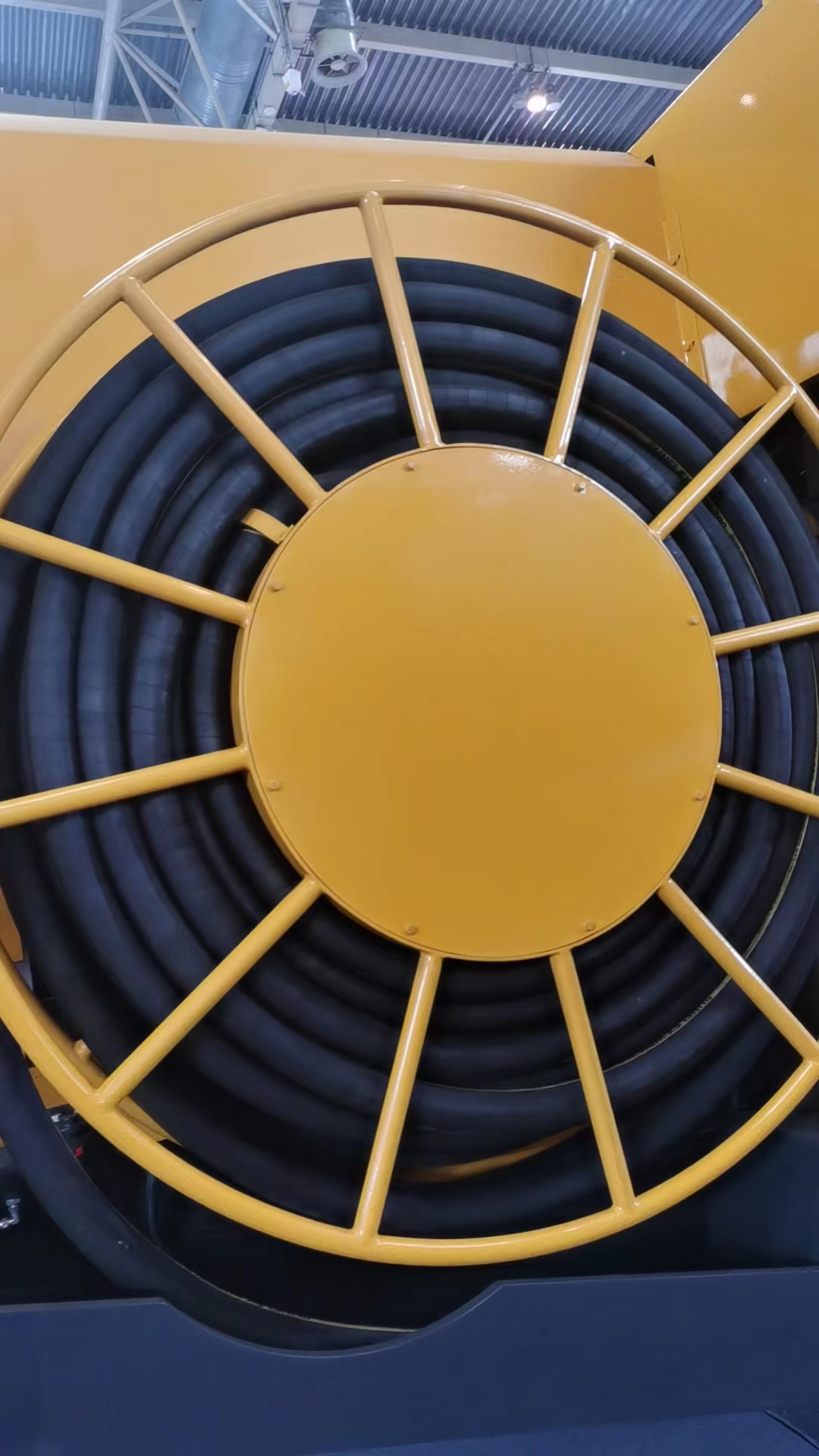

Hydraulic rubber hose factories have been at the forefront of industrial innovation, providing essential components for a variety of applications. These specialized facilities manufacture high-pressure hoses designed to withstand the rigorous demands of hydraulic systems, which are integral to everything from heavy machinery to sophisticated vehicles.

The production process within these factories is a testament to modern engineering. It begins with selecting durable materials such as synthetic rubber, polyester, and steel wire. These materials are meticulously combined in layers to create a flexible yet strong conduit capable of handling extreme pressures without bursting or leaking. The innermost layer, typically made from synthetic rubber like nitrile, provides chemical resistance and prevents fluid contamination. Surrounding this are layers of reinforcement, often braided steel or synthetic fibers, offering the structural integrity needed to manage high pressures. The outer cover may be made from materials resistant to oil, flame, ozone, or abrasion, depending on the hose's intended environment.

Advancements in technology have allowed these factories to streamline their operations. Automated processes reduce labor costs while ensuring consistency and precision in every foot of hose produced. Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use

Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use hydraulic rubber hose factories.

The significance of these factories extends beyond their production capabilities. They play a crucial role in supporting industries that rely on hydraulic power. In construction, mining, and agriculture, hydraulic hoses facilitate the operation of heavy equipment, making large-scale projects feasible. In transportation, they're essential for the transmission of power steering fluid and brake fluid in aircraft and automotive applications.

Moreover, hydraulic rubber hose factories contribute to environmental sustainability efforts by developing eco-friendly materials and recycling processes. This reduces waste and lessens the impact of manufacturing on ecosystems.

In conclusion, hydraulic rubber hose factories serve as the backbone of numerous sectors, producing a critical component that enables the smooth functioning of complex machinery. Their commitment to innovation, quality, and sustainability ensures that these facilities will continue to be vital for years to come.

hydraulic rubber hose factories.

The significance of these factories extends beyond their production capabilities. They play a crucial role in supporting industries that rely on hydraulic power. In construction, mining, and agriculture, hydraulic hoses facilitate the operation of heavy equipment, making large-scale projects feasible. In transportation, they're essential for the transmission of power steering fluid and brake fluid in aircraft and automotive applications.

Moreover, hydraulic rubber hose factories contribute to environmental sustainability efforts by developing eco-friendly materials and recycling processes. This reduces waste and lessens the impact of manufacturing on ecosystems.

In conclusion, hydraulic rubber hose factories serve as the backbone of numerous sectors, producing a critical component that enables the smooth functioning of complex machinery. Their commitment to innovation, quality, and sustainability ensures that these facilities will continue to be vital for years to come.

Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use

Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use Quality control is paramount; each batch undergoes rigorous testing to meet industry standards and ensure safety in use hydraulic rubber hose factories.

The significance of these factories extends beyond their production capabilities. They play a crucial role in supporting industries that rely on hydraulic power. In construction, mining, and agriculture, hydraulic hoses facilitate the operation of heavy equipment, making large-scale projects feasible. In transportation, they're essential for the transmission of power steering fluid and brake fluid in aircraft and automotive applications.

Moreover, hydraulic rubber hose factories contribute to environmental sustainability efforts by developing eco-friendly materials and recycling processes. This reduces waste and lessens the impact of manufacturing on ecosystems.

In conclusion, hydraulic rubber hose factories serve as the backbone of numerous sectors, producing a critical component that enables the smooth functioning of complex machinery. Their commitment to innovation, quality, and sustainability ensures that these facilities will continue to be vital for years to come.

hydraulic rubber hose factories.

The significance of these factories extends beyond their production capabilities. They play a crucial role in supporting industries that rely on hydraulic power. In construction, mining, and agriculture, hydraulic hoses facilitate the operation of heavy equipment, making large-scale projects feasible. In transportation, they're essential for the transmission of power steering fluid and brake fluid in aircraft and automotive applications.

Moreover, hydraulic rubber hose factories contribute to environmental sustainability efforts by developing eco-friendly materials and recycling processes. This reduces waste and lessens the impact of manufacturing on ecosystems.

In conclusion, hydraulic rubber hose factories serve as the backbone of numerous sectors, producing a critical component that enables the smooth functioning of complex machinery. Their commitment to innovation, quality, and sustainability ensures that these facilities will continue to be vital for years to come. Share

Latest news

-

High-Quality Distribution PTFE Hose for Industrial Applications

NewsJul.25,2025

-

High-Precision Hydraulic Hose Crimping Machine for Fast, Reliable Fittings

NewsJul.24,2025

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025