335345435

Nov . 25, 2024 20:01 Back to list

High Pressure Steel Wire Braided Hoses for Hydraulic Applications Manufacturing Solutions

High-Pressure Steel Wire Braided Hydraulic Hose An Essential Component in Modern Industry

In today's industrial landscape, where high efficiency and reliability are paramount, hydraulic systems play a critical role in powering a wide range of machinery and equipment. One of the key components that ensure the effectiveness of these systems is the high-pressure steel wire braided hydraulic hose. This article explores the importance, design, and manufacturing process of these hoses, as well as their applications across various industries.

Understanding Hydraulic Hose

A hydraulic hose is a flexible tubular device that allows the flow of hydraulic fluid from one component to another in a hydraulic system. The function of a hydraulic hose is not merely to conduct fluid; it must be able to withstand extreme pressures and harsh environmental conditions. High-pressure steel wire braided hydraulic hoses are specifically engineered for such demanding applications, featuring a robust construction that provides exceptional strength and flexibility.

Design and Construction

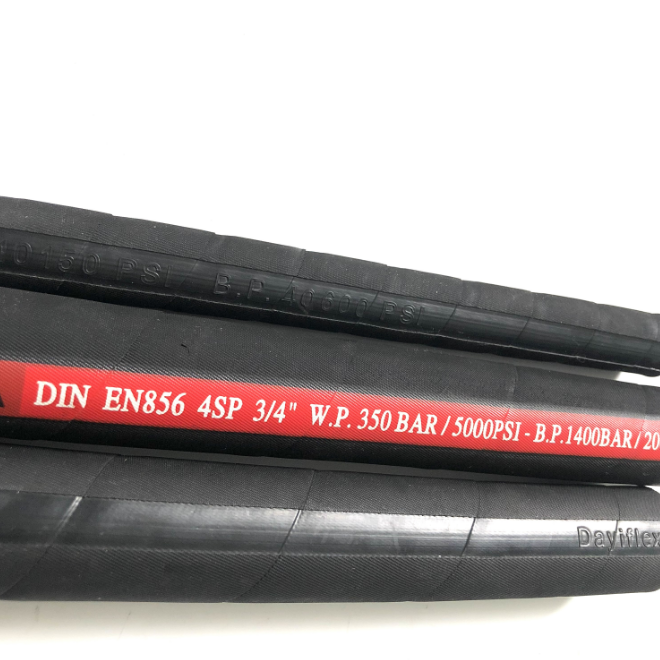

High-pressure hydraulic hoses comprise multiple layers that contribute to their strength and durability. The inner layer is typically made of synthetic rubber or thermoplastic, which is compatible with hydraulic fluids and minimizes permeability. Surrounding this inner layer are multiple strands of high-tensile steel wire, braided together to form a reinforcing layer that enhances the hose's ability to withstand high pressure. Finally, an outer layer of rubber or thermoplastic shields the hose from wear, abrasion, and environmental damage.

The unique braiding pattern of the steel wire enhances the hose's strength while maintaining flexibility, allowing it to bend and maneuver in tight spaces without compromising performance

. Typically, these hoses are rated for pressures often exceeding 5000 psi, making them suitable for high-demand applications.Manufacturing Process

high pressure steel wire braided hydraulic hose factory

The production of high-pressure steel wire braided hydraulic hoses involves several steps. First, the raw materials—synthetic rubber, steel wire, and other components—are sourced from reputable suppliers. The manufacturing process begins with the preparation of the inner tube, followed by the careful braiding of steel wires around it. This process requires precision and expertise to ensure that the braiding aligns perfectly and provides uniform strength.

Once the braiding is complete, the outer layer is applied, followed by curing in a controlled environment to enhance the properties of the elastomers. Quality control checks are integral to the process, with rigorous testing to ensure that the hoses meet industry standards for safety and performance.

Applications Across Industries

High-pressure steel wire braided hydraulic hoses are versatile and find applications in various sectors, including

1. Construction Used in excavators, bulldozers, and other heavy machinery that rely on hydraulic systems for operation. 2. Mining Essential for machinery that requires the transfer of hydraulic fluids under high pressure in demanding environments. 3. Agriculture Used in equipment such as tractors and combine harvesters, where hydraulic power is necessary for lifting and operating implements. 4. Automotive Integral to hydraulic braking systems and power steering applications, providing safety and improved vehicle handling.

Conclusion

In conclusion, high-pressure steel wire braided hydraulic hoses are essential components in modern industrial applications. Their robust design, manufactured with precision and quality in mind, makes them indispensable in ensuring the efficient operation of hydraulic systems. As industries continue to evolve, the demand for reliable and high-performance hydraulic hoses will remain critical, underscoring the importance of advancements in hose technology and manufacturing processes. Whether in construction, mining, agriculture, or automotive industries, these hoses facilitate the power that drives our modern world.

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025