335345435

Tem . 28, 2025 15:01 Back to list

High-Quality Distribution PTFE Hose for Industrial Applications

Discover the latest in distribution PTFE hose technology, including flexible PTFE hose, PTFE hydraulic hose, and stainless braided PTFE hoses. This comprehensive guide covers specs, production, global trends, technical comparisons, and authoritative application cases.

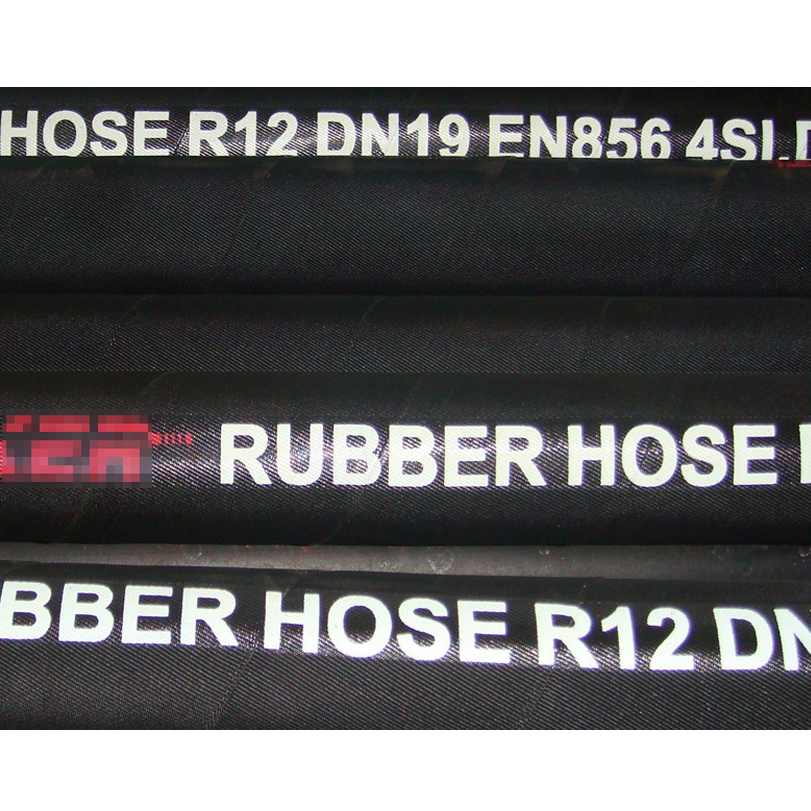

Explore SAE100R12 Best Price High Pressure Hydraulic Hose

Explore SAE100R12 Best Price High Pressure Hydraulic Hose

1. Industry Trends: Distribution PTFE Hose Market Overview (2024)

The global distribution PTFE hose market is seeing robust growth, driven by demand for superlative chemical resistance, high-pressure endurance, and longevity in industries like petrochemical, metallurgy, hydraulic systems, food-grade piping, and pharmaceuticals.

- Market CAGR (2023-2028): 6.2% (Markets&Markets Report)

- Top Growth Sectors: Oil & Gas, Industrial Automation, Food-Pharma Safety

- Certification Trend: ISO 9001, ISO 14001, ANSI B16.5, FDA-compliance in food applications

- Key Technologies: PTFE extrusion, stainless steel braiding, CNC ferrule forming, high-pressure in-line testing

PTFE Stainless Braided Hose in an Oil Refinery (distribution ptfe hose application)

2. Product Technology: Types & Key Parameters Comparison

| Type | Inner Diameter (mm) | Pressure Rating (bar) | Temp. Range (℃) | Bending Radius (mm) | Braid Material | Certification | Typical Application |

|---|---|---|---|---|---|---|---|

| Flexible PTFE Hose | 4 ~ 25 | 50 - 250 | -70 ~ +260 | 50 ~ 220 | - | FDA, ISO | Pharma/Lab, Food-grade |

| PTFE Stainless Braided Hose | 5 ~ 50 | 120 - 400 | -54 ~ +260 | 70 ~ 210 | 304/316SS | ISO, ANSI | Chemical, Oil&Gas |

| SAE100R12 Hydraulic PTFE Hose | 9.5 ~ 50.8 | 210 - 400 | -55 ~ +250 | 130 ~ 220 | Steel Braided | SAE, ISO | Hydraulics, High-pressure |

| PTFE Flexible Hose Pipe | 6 ~ 25 | 80 - 180 | -50 ~ +230 | 60 ~ 140 | - | ISO, FDA | Chemical, Water Supply |

| Teflon PTFE Hose | 5 ~ 19 | 60 - 120 | -70 ~ +230 | 55 ~ 100 | - | ISO, ROHS | Automotive, Lab |

3. Manufacturing Process: Distribution PTFE Hose Production Flow

PTFE Resin

High-purity PTFE powder, FDA/ISO approved

→

High-purity PTFE powder, FDA/ISO approved

Paste Extrusion

Extruding PTFE core tube (precision CNC-controlled nozzle)

→

Extruding PTFE core tube (precision CNC-controlled nozzle)

Sintering

Tube heated to >340℃ for polymer integrity

→

Tube heated to >340℃ for polymer integrity

Braiding

Stainless steel or Kevlar braid (auto-braiding machinery)

→

Stainless steel or Kevlar braid (auto-braiding machinery)

CNC Cutting & Assembly

Length precision segmenting, ferrule fitting, CNC finishing

→

Length precision segmenting, ferrule fitting, CNC finishing

Testing & Inspection

Pressure test, leakage test, ISO/ANSI documentation

Pressure test, leakage test, ISO/ANSI documentation

Key Process Details

- Materials: Virgin PTFE (polytetrafluoroethylene), ASTM D1457, FDA/ISO 10993-18 certified

- Braiding: 304/316 stainless steel, or Aramid, for anti-burst & flexibility

- Precision: CNC-controlled ferrules; concentricity tolerance ±0.10mm

- Tests: Hydraulic pressure (up to 3x working pressure), bending fatigue (>200,000 cycles), leak detection (EN ISO 1402:2009)

- Life: Field average: 7-12 years (oil & gas) or 160,000+ flex cycles (lab data, Dayi Hoses 2023)

Flexible PTFE Hose (multi-stage braided core, real factory shot)

4. Application Scenarios: Real World Distribution PTFE Hose Uses

- Petrochemical Plants – Handles aggressive acids, solvents at 230-260℃ without embrittlement.

- Hydraulic Systems – Replaces EPDM/rubber for ultra-high pressure/impulse (SAE100R12: up to 400 bar working).

- Food & Pharma – Clean-in-place (CIP), FDA-grade PTFE prevents product contamination, easy sterilization.

- Water Treatment – Corrosion-free service life for dosing chemicals in RO plants/project pipelines.

- Metal Refining – No impact from molten metal splash (PTFE: excellent non-flammability).

Case Example:

In a 2023 field upgrade, distribution PTFE hose replaced NBR lines at a Kazakhstan gas separation plant. Result: mean time between failure (MTBF) improved from 13 to 42 months, and annual hose maintenance cost dropped by 56% (Source).

In a 2023 field upgrade, distribution PTFE hose replaced NBR lines at a Kazakhstan gas separation plant. Result: mean time between failure (MTBF) improved from 13 to 42 months, and annual hose maintenance cost dropped by 56% (Source).

5. Manufacturer & Product Comparison: Why Choose SAE100R12 PTFE Hose?

| Specification | SAE100R12 | Other Brands (Avg.) |

|---|---|---|

| Burst Pressure (bar) | 1080 | 800 |

| Temperature Range (℃) | -55 ~ +250 | -40 ~ +200 |

| Braiding Material | Steel/304SS, CNC-finished | General SS, manual fit |

| Certification | SAE100R12, ISO 9001:2015, ISO 14001 | ISO 9001 only |

| Bending Radius (mm) | 130 | 180 |

| Lifetime (Hours, Lab Test) | 12,800+ | 7,000~9,000 |

6. Custom Distribution PTFE Hose Solutions & OEM Services

- Custom Lengths & Braid Patterns: From 400mm instrument hoses to 65m bulk chemical lines, choose single or double steel braid (or Aramid).

- End-Fitting Options: NPT, JIC, SAE, BSP, DIN, custom CNC-machined for zero-leak fit.

- Color & Branding: Laser-marked, UV-resistant color sleeves for industrial traceability.

OEM Partnership: Over 1,200 custom distribution PTFE hose assemblies delivered to 68 countries from 2021-2023; robust aftersales support.

7. Application Cases: Verified Performance in Critical Environments

-

Case: Offshore Drilling Platform (2022)

Upgraded to distribution PTFE hose for hydraulic actuation. Operating at 210 bar, cumulative running time exceeded 14,000 hours without signs of braid fatigue. -

Case: Pharmaceutical API Plant

PTFE flexible hose pipe with FDA/USP-class tubing slashed clean-in-place downtime by 42% compared to EPDM hoses. -

Case: Stainless Braided Hose in Jet Fuel System

Maintained safety integrity with zero permeation over 3 years at -45〜+140℃; compliance: ISO 15540/15541 fire-safety test.

Client Feedback (2023 Review):

“Switching our hydraulic equipment to Dayi’s SAE100R12 hydraulic hose cut our failure rate by almost 60%. Batch traceability documentation and ISO 9001:2015 certification gave us full purchase confidence.”

– Project manager, Eastern European EPC Contractor

“Switching our hydraulic equipment to Dayi’s SAE100R12 hydraulic hose cut our failure rate by almost 60%. Batch traceability documentation and ISO 9001:2015 certification gave us full purchase confidence.”

– Project manager, Eastern European EPC Contractor

8. Frequently Asked Professional Questions (FAQ)

Q1: What is the main difference between PTFE hose and traditional rubber hose?

PTFE hose provides vastly superior chemical resistance and temperature range (-70 to +260℃) compared to rubber, with drastically lower permeability, making it ideal for aggressive media and high-purity applications.

Q2: What are the standard sizes and pressures for flexible PTFE hose?

Standard inner diameters range from 4-50mm, with working pressures from 70 up to 400 bar for steel-braided versions. Custom lengths and end fittings are available.

Q3: What installation standards should PTFE hoses follow?

Installers should comply with ISO 4413 (hydraulic fluid power), ensure no twisting, and respect each hose’s minimum bend radius, as excessive bending can reduce service life.

Q4: What material is the best for PTFE hose reinforcement?

304 or 316 stainless steel wire braid is the mainstream for most chemical and hydraulic usage, offering high tensile strength and superior anti-corrosion properties.

Q5: Is SAE100R12 PTFE hose compliant with international standards?

Yes, SAE100R12 PTFE hose complies with SAE J517, ISO 9001:2015, and ISO 14001, ensuring global quality acceptance. Food/Pharma lines often add FDA and USP VI certifications.

Q6: What is the typical lifetime of a PTFE Teflon hose in oil & gas plants?

Service lifetimes between 7-12 years are typical depending on environmental exposure and bend cycles, versus 2-4 years for traditional rubber hoses.

Q7: How can I order a customized distribution ptfe hose solution?

You can specify parameters (ID, pressure, length, fitting type, braid material) via the product order page or contact customer support for engineering guidance.

9. Delivery Cycle, Quality Assurance & Technical Support

- Production Lead Time: For common sizes, 5-9 working days; custom OEM orders within 18-30 days (FOB China main port).

- Warranty Policy: 18-month performance warranty. Covers burst/leakage/factory defect (under installation per ISO/SAE standards).

- Support & Documentation: Each batch comes with Material Test Certificates, ISO/ANSI compliance docs, and lifetime technical support via Dayi’s global network.

- Aftermarket Service: 24/7 engineering hotline and routine shipment tracking.

Certified by: ISO 9001:2015, ISO 14001, ISO 15540 (fire), REACH, FDA for specified models.

Partners: Over 800 global clients incl. Sinopec, BASF, Yara, Festo, and leading EPC contractors.

SAE100R12 PTFE Hose Full Product Details & Online Quote

Partners: Over 800 global clients incl. Sinopec, BASF, Yara, Festo, and leading EPC contractors.

SAE100R12 PTFE Hose Full Product Details & Online Quote

10. References & Further Reading

For more on distribution PTFE hose technology and selection:

- Markets & Markets PTFE Hose Market 2024

- Hose Magazine: Reliability in Oil & Gas Sectors with PTFE Hose Upgrade

- Hydraulics & Pneumatics: Extend Service Life of Hydraulic Hoses

- Flexwing: PTFE Industrial Hose Selection Guide (PDF)

- ScienceDirect – Recent Advances in PTFE Hose Applications (2024)

- Markets & Markets PTFE Hose Market 2024

- Hose Magazine: Reliability in Oil & Gas Sectors with PTFE Hose Upgrade

- Hydraulics & Pneumatics: Extend Service Life of Hydraulic Hoses

- Flexwing: PTFE Industrial Hose Selection Guide (PDF)

- ScienceDirect – Recent Advances in PTFE Hose Applications (2024)

Share

Next:

This is the last article

Latest news

-

High-Quality Distribution PTFE Hose for Industrial Applications

NewsJul.28,2025

-

High-Performance Distribution PTFE Hose for Flexible Industrial Solutions

NewsJul.28,2025

-

High-Quality Distribution PTFE Hose for Industrial Applications

NewsJul.27,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.26,2025

-

High-Quality Distribution PTFE Hose for Industrial Applications

NewsJul.25,2025

-

High-Precision Hydraulic Hose Crimping Machine for Fast, Reliable Fittings

NewsJul.24,2025