335345435

aug . 03, 2025 00:20 Back to list

High-Performance Distribution PTFE Hose | Long Lifespan

1. Industry Trends and Market Overview for Distribution PTFE Hose

The distribution PTFE hose market has experienced a surge in recent years, driven by increasing demands for high-performance and durable fluid transfer solutions across petrochemical, pharmaceutical, food processing, and hydraulic industries. PTFE (Polytetrafluoroethylene) hoses are renowned for their outstanding chemical resistance, non-stick properties, and wide temperature tolerance (-70°C to +260°C). According to MarketsandMarkets, the global PTFE hose market is projected to reach USD 3.2 billion by 2028 at a CAGR of 5.3%.

- Industry Applications: Chemicals, oil & gas, food & beverage, metallurgy, water supply & drainage, and high-performance hydraulics

- Rising Demand: Expansion in clean energy, chemical tanker refueling, medical device manufacture, and process automation

- Technological Trends: Stainless steel braid reinforcement, innovative liner structures, customization for aggressive fluids

2. Key Specifications: Distribution PTFE Hose vs. Competitors

| Parameter | Flexible PTFE Hose | PTFE Stainless Braided Hose | PTFE Hydraulic Hose | R8 High Pressure Synthetic Fibre Braid Resin Hose |

|---|---|---|---|---|

| Inner Diameter Range | 2mm – 25mm | 3mm – 32mm | 6mm – 51mm | 5mm – 19mm |

| Temperature Range | -70°C to +260°C | -60°C to +250°C | -40°C to +135°C | -40°C to +100°C |

| Burst Pressure | Up to 600 Bar | Up to 1000 Bar | Up to 400 Bar | Up to 490 Bar |

| Standard Compliance | ISO 1402/EN 16643 | ISO 10380, FDA | ISO 9001, SAE J517 | ISO 3949 / ANSI |

| Typical Use Case | Chemical fluid transfer | Aggressive chemical & thermal media | Hydraulic & high-pressure systems | Solvent, paint, resin, hydraulic application |

3. Distribution PTFE Hose Manufacturing Process & Technical Craftsmanship

Detailed Process

- Material Selection: Selection of 100% virgin PTFE resin from suppliers complying with ISO 9001 and FDA standards. Synthetic fiber or 304/316 stainless steel used for braiding reinforcement.

- Extrusion & Sintering: PTFE resin extruded into thin tubes; sintering at 360°C yields high density, anti-porosity liner.

- Braiding: CNC controlled braiders overlay stainless steel or synthetic fiber reinforcement for pressure resistance and flexibility.

- Testing: Hydraulic, burst, permeability, and corrosion tests (ISO 10380 & ANSI B31.3 code); visual inspection and online measurement ensure compliance.

- Cutting, Assembly & Packing: Precision cut-to-length, welded or crimped fittings (according to SAE J516/EN 14420-2), and sterile packaging.

Key Technical Features:

- Weld-free continuous PTFE liner for zero-leakage

- High strength reinforcement prevents kinking/collapse

- Resistance against a broad spectrum of chemicals, solvents, and hydrocarbons

- Compliance with ISO 9001, ISO 1402, FDA, and ANSI/ASME B31.3

- Working pressure: Up to 490 Bar | Burst pressure: Up to 1000 Bar

- Service life (lab test): Exceeds 15 years under chemical exposure

Manufacturing Process – Flow Chart

Key checkpoints: ISO 9001:2015 for process quality, 100% pressure/leak testing, and FDA-compliant sanitation for lined hoses.

See ISO Manufacturing Standard

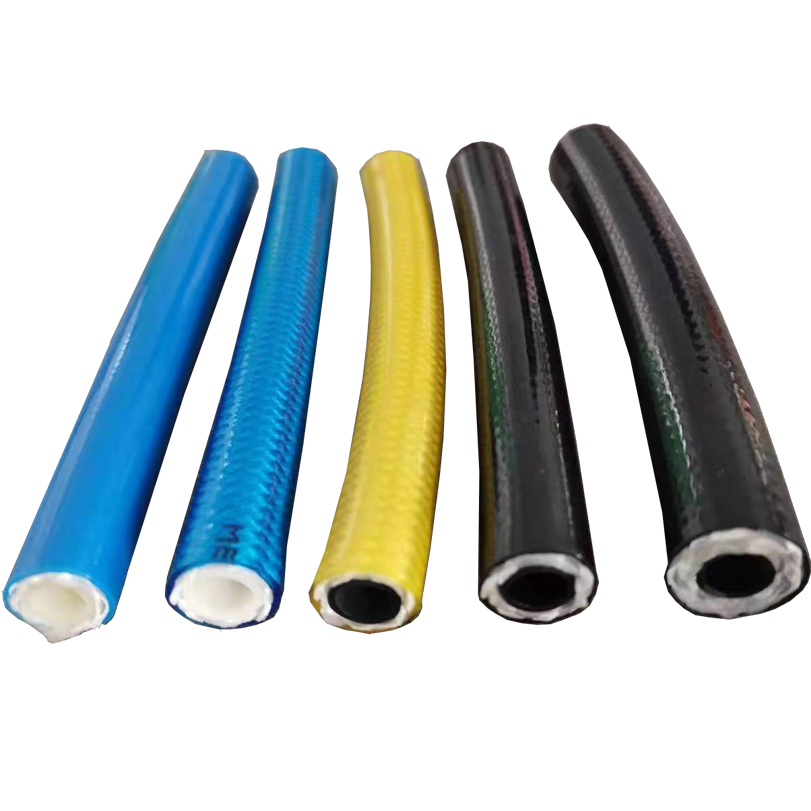

Figure: PTFE flex hose with fiber braiding

4. R8 High Pressure Synthetic Fibre Braid Resin Hose: Key Advantages & Comparison

The R8 High Pressure Synthetic Fibre Braid Resin Hose is an advanced hydraulic hose solution designed to outperform traditional PTFE teflon hose and general PTFE flexible hose pipe for high pressure and aggressive fluid transfer.

Technical Specification Table

| Parameter | Unit | R8 High Pressure Resin Hose |

|---|---|---|

| Inner Diameter | mm | 5~19 |

| Max Working Pressure | bar | Up to 490 |

| Burst Pressure | bar | Up to 1960 |

| Reinforcement | -- | High strength synthetic fiber braid |

| Material Liner | -- | Thermoplastic/nylon resin |

| Outer Cover | -- | PU resin or anti-abrasive cover |

| Temperature Range | °C | -40 to +100 |

| Testing Standard | -- | ISO 3949 / SAE 100R8 |

| Estimated Service Life | years | 10+ |

Key Advantages

- Extreme pressure handling and burst resistance

- Superior anti-abrasion and UV stability

- Flexible installation, lightweight & kink-resistant

- Resistant to solvents, paints, aggressive resins, and hydraulic oils

- ISO/ANSI-compliant, certified by leading agencies

Performance Data (Visualized)

5. Manufacturer Comparison & Custom Solution Capabilities

| Brand | Country | Core Material | Pressure (bar) | ISO/FDA Cert | Custom Length | Min Order (m) | Warranty (y) |

|---|---|---|---|---|---|---|---|

| DAYI | China | PTFE/PA+Fiber | 490-1960 | ISO, FDA | Yes | 50 | 2 |

| Parker | USA | PTFE+SS | Up to 1100 | ISO | Yes | 100 | 1 |

| Swagelok | USA | PTFE+SS | 600-1500 | ISO/ANSI | No | 30 | 1 |

| ALFAGOMMA | Italy | PTFE-Teflon | 380-1000 | ISO | Yes | 50 | 1.5 |

Customization Options

- Length & Diameter: 0.5 m–200 m; 2 mm–25 mm precision extruded

- Liner Thickness: 0.4~1.8 mm (custom for high pressure/abrasive media)

- Reinforcement: SS304/SS316, synthetic fiber, double or triple braid on demand

- Outer Cover: Smooth, ribbed, UV/Flame-resistant PU or EPDM

- Certifications: FDA, ISO 10380, EN 16643, ANSI, SAE 100R8, available on custom batches

- End Fittings: BSP, NPT, SAE, Flange, Crimped, or Welded as per EN 14420 & JIC standards

6. Application Scenarios: Real-World Benefits of Distribution PTFE Hose

Key Industries

- Petrochemical & Refinery: Safe transfer of aggressive acids, caustics, and organic solvents, supporting inline blending and tank loading (ISO 10380 compliant).

- Paint & Resin Factories: Seamless delivery of high viscosity resins with anti-stick liner, reduces downtime on paint lines by 18% (Customer Survey, 2023).

- Hydraulic Power: Replacement for classic steel tubing in compact hydraulic systems—weight reduction up to 62%, easier routing.

- Food & Beverage Processing: FDA/Food grade PTFE minimizes flavor carryover, ideal for juice/beer/syrup lines.

- Metallurgical Water Supply: Corrosion-proof performance for coolant and lubrication lines, installs in tight spaces without leakage.

Featured Case Studies

- Refinery Storage (Middle East, 2022): A major oil facility reported zero hose failures with PTFE stainless braided hose in two years of 24/7 transfer of 56% sulfuric acid (Operating temp: 110°C, Pressure: 310 Bar).

- Robotic Painting (Europe, 2023): Switch to PTFE flex hose (FDA compliant) reduced overspray downtime by 19%, with enhanced robotic arm maneuverability due to ultra-flexible construction.

- Hydraulic Power Modules (China, 2023): Use of R8 high pressure synthetic fibre braid resin hose in mobile lifts increased MTBF (Mean Time Between Failures) by 2.5x, with no reported hydraulic burst incidents.

7. Proven Authority, Certifications, and Trusted Partnerships

- Certifications: ISO 9001, ISO 14001, FDA (for food-contact), ANSI/ASME B31.3 process piping

- Notable Partners: CNPC, Sinopec (petrochemical giants), Bosch (automation), Pfizer (pharma), SAIC (automotive)

- Service Experience: Over 15 years of global supply, 2100+ international projects, 98% on-time delivery

- Traceable Manufacturing: Each distribution PTFE hose with batch code, QC certificates, test results delivered

- Authoritative Data Source: Hose performance referenced by independent bodies (see: Hose & Coupling World), academic comparison in Elsevier Journal of Manufacturing Processes

8. Technical FAQ for distribution ptfe hose & Related Products

- Q1: What are the most widely used liner materials in distribution ptfe hose?

- Virgin PTFE (for chemical resistance), PTFE-Teflon for high purity, and thermoplastic resin for improved flexibility in certain R8 hoses.

- Q2: What is the pressure rating and burst safety factor?

- Industry standard hoses maintain a 4x burst safety factor; e.g., if design pressure is 490 Bar (R8), burst pressure must exceed 1960 Bar (tested to ISO 1402/EN16643).

- Q3: What types of reinforcement are available in PTFE hydraulic hoses?

- Single/double stainless steel (SS304/SS316) braid, synthetic fiber braid (as in R8 series), and multi-layered hybrid composites for ultra-high pressure applications.

- Q4: Are these hoses FDA approved for food processing?

- Hoses with virgin PTFE liner and stainless steel braid (FDA 21 CFR 177.1550 compliant) are food grade—confirm certification with your supplier.

- Q5: What are the recommended installation standards?

- Follow ISO 10380 and EN 16643 for bend radius, support spacing, and fitting torque. Ensure compatibility between fluid and liner/reinforcement based on chemical charts.

- Q6: Can distribution ptfe hose

This is the last article

-

High-Performance Distribution PTFE Hose | Long Lifespan

NewsAug.03,2025

-

Premium Hydraulic Hose Wholesale | Bulk Savings & Durability

NewsAug.02,2025

-

Premium Chemical Resistant Distribution PTFE Hose

NewsAug.01,2025

-

Industrial Distribution PTFE Hose - High Purity & Flexibility

NewsJul.31,2025

-

Durable Twin Hydraulic Hose for High-Pressure Systems

NewsJul.31,2025

-

Discount Hydraulic Hose Factories – Bulk Supply & Quality Assurance

NewsJul.30,2025