335345435

Авг . 11, 2025 00:20 Back to list

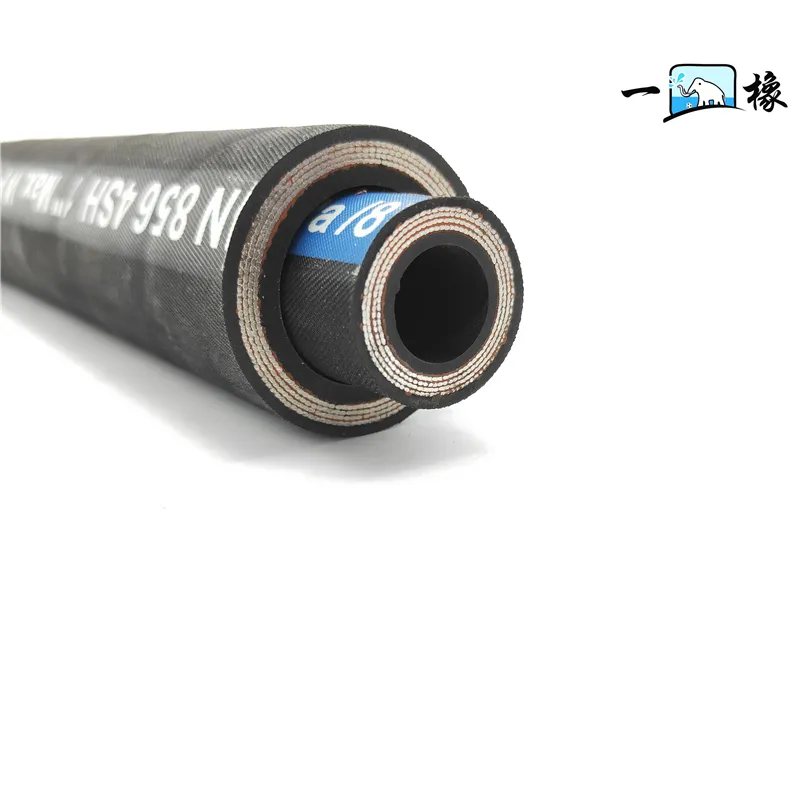

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

In the demanding landscape of modern industrial operations, the integrity and performance of hydraulic systems are paramount. These sophisticated systems, which power everything from heavy construction machinery and large-scale mining equipment to complex manufacturing lines and precision automation processes, rely intrinsically on robust and reliable components for efficient fluid power transmission. Among these critical elements, the hydraulic hose stands out as a fundamental conduit for dynamic power transfer, requiring exceptional durability, precision engineering, and unwavering reliability under extreme conditions. Specifically, the 4sp hydraulic hose, meticulously designed to meet the rigorous EN 856 4SP standard, represents a pinnacle of high-pressure hydraulic fluid conveyance technology. This specialized hose is expertly engineered to withstand extremely high internal pressures, intense pressure surges, and challenging operating environments, making it an indispensable component in a wide array of industrial applications where safety, efficiency, and prolonged longevity are non-negotiable operational imperatives. Its advanced construction, typically involving multiple layers of high-tensile steel wire spirals, provides superior resistance to both constant static pressure and dynamic impulse cycles, as well as external abrasive forces, ensuring consistent operational integrity and minimizing the risk of premature failure. The strategic selection of such a high-performance hydraulic hose, specifically the EN856 4SP Black Cloth Cover Hydraulic Hose, is not merely a routine procurement decision but a critical engineering choice that directly impacts overall system reliability, significantly influences maintenance schedules and associated costs, and ultimately determines the comprehensive operational efficiency of the machinery it serves. Understanding its inherent technical specifications, the intricacies of its manufacturing processes, and its diverse application scenarios is therefore paramount for engineers, procurement managers, and technical decision-makers who are committed to optimizing their hydraulic power transmission solutions and achieving superior long-term performance. This comprehensive overview aims to delve deeply into the core aspects of this essential component, providing invaluable insights into its technical superiority, its prominent market relevance in critical industries, and the strategic advantages it offers for robust industrial implementation.

The industrial sector's relentless pursuit of higher efficiency, increased automation, and enhanced safety standards has significantly amplified the demand for advanced and resilient hydraulic components worldwide. Within this rapidly evolving technological landscape, the performance requirements for hydraulic hoses have become increasingly stringent, compelling leading manufacturers to continuously innovate and deliver products that not only meet but often substantially exceed conventional performance benchmarks. The 4sp hydraulic hose is a prime embodiment of this technological evolution, meticulously engineered to conform to and often surpass the demanding specifications outlined in the European Standard EN 856. This authoritative standard meticulously details the comprehensive requirements for rubber hoses and their assembled components specifically for hydraulic applications, systematically classifying hoses based on critical parameters such as their maximum working pressure rating, their permissible temperature range for various fluids, and their precise fluid compatibility. The "4SP" designation specifically refers to hydraulic hoses incorporating four meticulously applied spiral layers of high-tensile steel wire reinforcement, a key structural feature that distinctly differentiates them from braided hoses or those with fewer spiral layers, and also from other high-pressure spiral hoses like EN856 4SH, which typically feature even higher pressure ratings but often come with a larger minimum bend radius. This distinctive multi-spiral structural design bestows upon the EN856 4SP hose exceptional resistance to cyclic pressure impulses and formidable external forces, rendering it an ideal and robust solution for highly dynamic applications where hoses are routinely subjected to constant flexing, significant vibration, and considerable mechanical stress. From heavy-duty construction equipment operating tirelessly in the most arduous environments to sophisticated industrial machinery demanding precise and high-volume fluid transfer at extreme pressures, the inherent reliability of the hydraulic hose 4sp is absolutely foundational to maintaining uninterrupted operational continuity and proactively preventing costly and disruptive unscheduled downtime. Its inherently robust and durable construction ensures an extended service life, which in turn significantly reduces the frequency of replacements and substantially contributes to a much lower total cost of ownership over the entire operational lifespan of the machinery, making it an unequivocally preferred choice for industries that prioritize long-term reliability, unparalleled system integrity, and maximum operational uptime above all else.

Industry Trends and the Evolving Landscape of Hydraulic Hoses

The global hydraulic hose market is undergoing profound and dynamic transformations, driven by several overarching industry trends that directly influence the development, adoption, and performance requirements of advanced products like the 4sp hydraulic hose. A paramount trend is the escalating demand for significantly higher operating pressures and broader temperature ranges within hydraulic systems across an increasingly diverse array of industrial sectors, including but not limited to heavy construction, mineral extraction and mining, advanced agriculture, and precision manufacturing. This pervasive escalation in performance requirements necessitates the deployment of hydraulic hoses that can reliably and safely transmit immense hydraulic power without compromising overall system safety or component longevity, even when operating under the most extreme and challenging conditions. Consequently, there is an intensified emphasis on cutting-edge materials science, which is driving the rapid development of innovative synthetic rubber compounds for both the inner tubes and outer covers. These advanced compounds offer superior chemical resistance to a wider array of hydraulic fluids, exceptional abrasion resistance against external wear and tear, and remarkable temperature tolerance across a broader spectrum, enhancing the hose's adaptability. Furthermore, the pervasive industry push for greater energy efficiency in industrial machinery is actively prompting substantial innovations in hydraulic system design, where optimized fluid flow characteristics and minimal pressure drop through the hoses contribute significantly to overall system efficiency and reduced operational costs. This involves meticulously refining hose internal diameters, ensuring ultra-smooth inner surfaces to reduce turbulence, and employing advanced reinforcement structures that proactively maintain precise dimensional stability under varying pressure loads, thereby minimizing inherent energy losses typically associated with turbulent fluid flow. The contemporary market is also keenly observing a trend towards more compact and inherently flexible hose designs, particularly crucial in applications where physical space is severely limited, all without sacrificing the critical pressure rating or the inherent durability that modern industrial operations demand. This multifaceted requirement necessitates ingenious reinforcement techniques and sophisticated material formulations that collectively allow for significantly smaller bend radii while rigorously maintaining the hose's structural integrity and dynamic performance.

The ongoing wave of digitalization and the burgeoning development of the Internet of Things (IoT) are also beginning to exert a substantial influence on the hydraulic hose industry, albeit more indirectly, by profoundly impacting advanced predictive maintenance strategies and real-time operational monitoring. While the direct embedding of sophisticated sensors into hydraulic hoses is still in its nascent stages, the pervasive trend towards the development and implementation of smart, interconnected equipment implies that critical hydraulic system performance data, including precise measurements of pressure, temperature, and fluid flow rates, can be continuously monitored in real-time. This invaluable data, when rigorously analyzed using advanced analytics and machine learning algorithms, can provide actionable insights that inform highly precise and proactive maintenance schedules for essential components like the hydraulic hose 4sp, enabling the timely and strategic replacement of components before any failure actually occurs. This proactive approach significantly minimizes unscheduled and costly downtime, while simultaneously elevating overall operational safety standards across the board. Sustainability remains another overwhelmingly critical trend driving innovation within the sector, with manufacturers increasingly prioritizing the development and utilization of eco-friendly materials and adopting advanced manufacturing processes that significantly reduce their overall environmental footprint. This comprehensive focus includes actively exploring recyclable materials, diligently minimizing waste generation throughout the entire production cycle, and meticulously designing hoses with inherently extended service lives to substantially lessen the frequency of material disposal. Regulatory compliance also continues to profoundly shape the market landscape, with increasingly stringent safety standards and certifications (such as ISO, ANSI, and the well-established EN standards) mandating demonstrably higher quality and more rigorously tested hydraulic components. Leading manufacturers are making substantial investments in state-of-the-art testing facilities and implementing sophisticated quality control measures to ensure that their products not only meet but often considerably exceed these stringent regulatory requirements, thereby providing an unparalleled layer of assurance and confidence to discerning end-users and industry stakeholders. These converging trends collectively underscore the relentless and continuous innovation occurring within the hydraulic hose sector, strategically positioning high-performance products like the EN856 4SP as truly critical enablers for sustained modern industrial progress and technological advancement.

Detailed Manufacturing Process of EN856 4SP Hydraulic Hose

The meticulous production of a high-quality 4sp hydraulic hose, such as the EN856 4SP Black Cloth Cover Hydraulic Hose, is an intricate and sophisticated multi-stage manufacturing process that imperatively demands precision engineering, cutting-edge material science expertise, and exceptionally stringent quality control measures at every step. This complex journey commences with the highly meticulous selection and precise preparation of raw materials, which are undeniably foundational to the hose's ultimate performance characteristics and its unwavering reliability in demanding operational environments. The innermost layer, known as the inner tube, which is the first component to come into direct contact with the hydraulic fluid, is typically manufactured from a high-performance synthetic rubber compound, most commonly Nitrile Butadiene Rubber (NBR) or Chloroprene Rubber (CR). These specific compounds are deliberately chosen for their outstanding fluid compatibility, excellent resistance to elevated temperatures, and notably low permeability to a wide range of hydraulic oils and chemicals. This carefully formulated rubber compound is then precisely extruded through a specialized die to form a seamless, perfectly uniform tube with exact dimensional tolerances. Any minute imperfections introduced at this crucial stage, even minor variations in thickness or surface irregularities, can potentially lead to fluid leakage, premature hose degradation, or catastrophic failure, thereby profoundly highlighting the critical importance of precise material formulation, rigorous temperature control during extrusion, optimized extrusion speed, and meticulously designed die geometry. Following the initial extrusion, the inner tube often undergoes a controlled preliminary curing process or precise cooling to stabilize its dimensions and mechanical properties before the subsequent reinforcement layers are applied. The uncompromised integrity and uniformity of this inner layer are absolutely critical for preventing any potential fluid contamination, ensuring impeccably efficient fluid flow dynamics, and directly impacting the energy efficiency and overall service life of the entire hydraulic system within which the hose is destined to be deployed. Furthermore, the judicious selection of the specific rubber compound for the inner tube also dictates the hose's precise suitability for various hydraulic fluids, including petroleum-based oils, water-glycol solutions, and advanced synthetic esters, thus ensuring broad and essential application versatility across diverse industrial contexts.

The fundamental and core strength of the EN856 4SP hydraulic hose is derived directly from its meticulously engineered reinforcement layers, which are critical for its high-pressure capabilities. Subsequent to the flawless formation of the inner tube, multiple concentric layers of exceptionally high-tensile steel wire are precisely spiraled around it. For the specific construction of a 4sp hydraulic hose, this highly specialized process meticulously involves applying four distinct and separate layers of spiraled wire. Each individual layer is applied with remarkably precise tension, a consistent and optimized pitch, and an exact angular alignment, collectively ensuring unparalleled structural integrity and formidable pressure resistance. The spiraling process, inherently distinct from braiding techniques, is specifically chosen because it provides exceptional resistance to rapid pressure impulses and sustains extremely high static pressures with superior efficacy. This is largely due to the fact that the steel wires are laid predominantly parallel to the hose's longitudinal axis, thereby creating a more uniform and highly efficient distribution of stress throughout the hose wall. Critically, between each successive steel wire reinforcement layer, a specialized adhesion layer, typically comprising a thin, carefully formulated layer of rubber, is expertly applied to ensure superlative bonding between the wire and rubber components. This prevents any potential delamination, a common failure mode, especially when the hose is subjected to intense and repetitive dynamic pressure cycles. This meticulous, multi-layered spiraling is unequivocally crucial for the hose's inherent ability to reliably withstand the immense internal pressures (e.g., routinely up to 450 bar, or approximately 6525 PSI, for certain sizes) for which it has been meticulously designed, without any undesirable bulging, significant expansion, or catastrophic rupturing. The absolute precision of the sophisticated spiraling machinery and the uncompromised quality of the high-tensile steel wire are of paramount importance, as even slight inconsistencies can inadvertently create critical weak points within the hose structure. This complex and highly robust reinforcement structure ensures that the hydraulic hose 4sp consistently maintains its precise dimensional stability and effectively resists unwanted elongation or contraction under varying and often fluctuating pressure loads. This characteristic is vitally important for maintaining consistent system performance, ensuring precise operational control, and proactively preventing hose fatigue, which could otherwise lead to premature failure in highly dynamic and demanding industrial environments.

The final and outermost structural component of the hose is the external cover, which serves a critical protective role by shielding the underlying inner layers from a myriad of external aggressors, including physical damage, severe abrasion, environmental weathering, and harmful ozone degradation. For the EN856 4SP Black Cloth Cover Hydraulic Hose, this protective cover is typically formulated from a highly durable synthetic rubber compound, such as a Styrene-Butadiene Rubber (SBR) or a meticulously blended Nitrile Butadiene Rubber/Polyvinyl Chloride (NBR/PVC) compound. This cover frequently features a distinctive textile (cloth) impression on its surface, which not only enhances grip and contributes to a professional aesthetic but also adds an additional layer of tactile resistance. This cover layer is also precisely extruded over the reinforced core. The judicious selection of the cover material is absolutely critical for significantly enhancing the hose's overall service life, especially when deployed in exceptionally harsh and unforgiving operating environments, such as those routinely encountered in large-scale mining operations, heavy construction sites, or demanding offshore oil and gas applications, where constant exposure to corrosive chemicals, intense UV radiation, extreme temperatures, and significant physical impact is commonplace. After the outer cover has been meticulously applied, the entire hose undergoes a vital vulcanization process. During this stage, the hose is subjected to carefully controlled conditions of elevated heat and precise pressure within a specialized autoclave. This irreversible chemical process transforms the raw rubber compounds into a much more stable, inherently elastic, and remarkably durable material, thereby permanently and cohesively bonding all individual layers together into a monolithic structure. Vulcanization is the decisive step that enables the hose to achieve its final, full mechanical properties, including its optimal flexibility, its rated working and burst pressures, and its specified temperature resistance capabilities. Post-vulcanization, every single hose undergoes rigorous and comprehensive testing in strict accordance with authoritative international standards, most notably ISO 1436 or the specific EN 856 criteria. These exhaustive tests include, but are not limited to, catastrophic burst pressure tests to determine ultimate strength, highly repetitive impulse tests designed to simulate millions of pressure cycles and assess fatigue life, critical cold flexibility tests to ensure performance in sub-zero temperatures, rigorous ozone resistance tests to prevent environmental degradation, and precise dimensional checks to confirm adherence to specifications. Only those hoses that successfully pass all these stringent and uncompromising quality control measures are approved and released for distribution, thereby providing an unwavering assurance that every 4sp hydraulic hose manufactured meets the absolute highest performance, safety, and reliability standards for its intended applications in demanding sectors such as petrochemicals, metallurgy, and complex water management systems.

The entire manufacturing process for a high-quality 4sp hydraulic hose incorporates several critical and strategically placed quality control points to ensure the final product's absolute conformity to the stringent EN 856 standards and often to exceed them, delivering exceptional performance. This comprehensive quality assurance begins with the initial, rigorous inspection of all incoming raw materials, meticulously scrutinizing them for purity, consistency, and adherence to precise chemical compositions and physical properties. In-process checks are continuously performed, including real-time monitoring of inner tube dimensions during extrusion, precise measurement of wire tension and pitch during the intricate spiraling process, and verification of cover thickness and uniformity. Advanced sensor technologies are frequently employed throughout these stages to measure and control critical parameters such as extrusion temperature, speed, and pressure, ensuring unparalleled uniformity and minimizing variations in the final product. Post-vulcanization, a comprehensive suite of non-destructive testing methods is executed on every single hose batch. These include meticulous visual inspections for any surface defects, precise dimensional measurements (encompassing inner diameter, outer diameter, and overall length), and thorough flexibility tests to confirm the hose meets its specified pliability. Furthermore, destructive tests, which include definitive burst pressure tests and cyclic impulse fatigue tests, are systematically conducted on representative samples from each production lot. These destructive tests are crucial for validating the overall design integrity and manufacturing process against the specified performance criteria for the hydraulic hose 4sp. For instance, the EN 856 standard rigorously mandates a minimum impulse life of 200,000 cycles for 4SP hoses when subjected to their maximum working pressure at a specified temperature. Successfully meeting or, ideally, significantly exceeding these stringent standards is a profound testament to the manufacturer's unwavering commitment to superior quality and the product's inherent and proven reliability. The utilization of highly specialized equipment, such as advanced impulse testing machines that meticulously cycle pressure from nearly zero to the maximum working pressure at high frequencies, enables manufacturers to accurately simulate many years of arduous service life in a compressed timeframe of just days or weeks, thereby rigorously proving the hose's long-term endurance and fatigue resistance. This comprehensive and multi-layered testing regimen ensures that the finished 4sp hydraulic hose provides an exceptional service life, substantially enhances operational safety, and delivers consistently reliable performance in the most demanding and unforgiving environments, whether it be in extensive large-scale mining operations, high-stakes offshore drilling platforms, or highly precise industrial automation systems.

Technical Parameters and Performance Data for EN856 4SP Hydraulic Hose

A profound understanding of the detailed technical parameters of the EN856 4SP Black Cloth Cover Hydraulic Hose is absolutely critical for proper system design, meticulous component selection, and ultimately, ensuring the unwavering safety and peak efficiency of hydraulic machinery. These precisely defined parameters comprehensively delineate the hose's inherent capabilities and its specific operational limitations, thereby guaranteeing that it can safely and efficiently function within its specified hydraulic systems without risk of failure or performance degradation. The EN 856 4SP standard sets forth rigorous and precise requirements for key characteristics such as the maximum working pressure (WP), the minimum burst pressure, the permissible operating temperature range, and the critical minimum bend radius, among other vital specifications. Working pressure (WP) unequivocally refers to the maximum internal pressure that a 4sp hydraulic hose can safely and continuously withstand during its normal operational cycle, typically expressed in units of Bar or PSI. Burst pressure, in stark contrast, represents the theoretical pressure at which the hose is expected to rupture or experience catastrophic failure, and this value is invariably and significantly higher than the specified working pressure, providing an indispensable safety margin. For hydraulic hoses, this safety factor is typically a conservative 4:1, meaning the burst pressure is always at least four times the maximum working pressure, offering a robust safeguard against unforeseen pressure spikes or system malfunctions. The temperature range, universally specified in degrees Celsius, unequivocally indicates the safe operating temperature limits for both the hydraulic fluid conveyed and the ambient environmental conditions surrounding the hose. Operating a hose consistently outside its specified temperature range, whether too hot or too cold, can lead to irreversible degradation of the inner tube and/or the outer cover material, severely affecting its flexibility, compromising its fluid compatibility, and drastically reducing its overall service life. The minimal bend radius, another critically important parameter, precisely dictates the smallest radius to which a hydraulic hose 4sp can be bent during installation and operation without causing structural damage to its internal reinforcement, significantly impeding fluid flow, or inducing premature fatigue failure, a consideration that is profoundly crucial for successful installation in spatially confined areas within complex machinery.

The overall performance and operational effectiveness of the 4sp hydraulic hose are directly and intrinsically influenced by its physical dimensions, with particular emphasis on the nominal bore (DN) or inner diameter (ID), which profoundly impacts the fluid flow rate and the associated pressure drop across the hose length. Generally, larger internal diameters facilitate higher fluid flow rates with proportionally less pressure loss, thereby enhancing energy efficiency, but these hoses also tend to be physically larger, heavier, and possess a larger minimum bend radius, posing installation challenges in constrained spaces. Therefore, selecting the appropriate hose size involves a meticulous balance between the specific fluid flow requirements, the necessary pressure ratings, and the practical physical constraints of the installation environment. For the EN856 4SP, commonly available sizes span a significant range, typically from DN 10 (equivalent to 3/8 inch) up to DN 50 (equivalent to 2 inches) or even larger diameters for specialized applications, with each specific size possessing distinct pressure ratings tailored to its dimensions. For illustrative purposes, a smaller DN 10 hose might boast an impressive working pressure rating of 450 Bar (approximately 6525 PSI), whereas a much larger DN 50 hose might be conservatively rated for 165 Bar (approximately 2390 PSI), effectively demonstrating the inverse relationship between the hose's internal diameter and its maximum working pressure for a given structural construction. The hose's weight, typically quantified in kilograms per meter (kg/m), also represents a vital practical consideration for engineers involved in the installation process and for designing appropriate support structures, particularly for exceptionally long hose runs or in mobile machinery applications where overall weight significantly impacts vehicle performance and fuel efficiency. A comprehensive understanding of these intricate interdependencies between dimensions, pressure ratings, and physical properties is undeniably vital for expert engineers who are meticulously designing hydraulic circuits. This understanding ensures that the selected 4sp hydraulic hose not only rigorously meets the exacting pressure and flow demands of the system but also physically fits seamlessly within the machinery's spatial envelopes, and, most critically, delivers a long, consistently reliable, and safe service life under all anticipated and fluctuating operating conditions, thereby optimizing both performance and total cost of ownership.

EN856 4SP Hydraulic Hose Typical Performance Specifications

| Hose Size (DN / Inch) | Inner Diameter (mm / Inch) | Working Pressure (Bar / PSI) | Burst Pressure (Bar / PSI) | Min. Bend Radius (mm / Inch) | Weight (kg/m / lbs/ft) |

|---|---|---|---|---|---|

| DN 10 (3/8") | 9.5 / 0.375 | 450 / 6525 | 1800 / 26100 | 180 / 7.1 | 0.65 / 0.44 |

| DN 12 (1/2") | 12.7 / 0.500 | 400 / 5800 | 1600 / 23200 | 210 / 8.3 | 0.85 / 0.57 |

| DN 16 (5/8") | 15.9 / 0.625 | 350 / 5075 | 1400 / 20300 | 250 / 9.8 | 1.10 / 0.74 |

| DN 19 (3/4") | 19.0 / 0.750 | 300 / 4350 | 1200 / 17400 | 300 / 11.8 | 1.45 / 0.97 |

| DN 25 (1") | 25.4 / 1.000 | 250 / 3625 | 1000 / 14500 | 380 / 15.0 | 2.10 / 1.41 |

| DN 32 (1-1/4") | 31.8 / 1.250 | 225 / 3260 | 900 / 13050 | 480 / 18.9 | 3.10 / 2.08 |

| DN 38 (1-1/2") | 38.1 / 1.500 | 210 / 3045 | 840 / 12180 | 550 / 21.7 | 3.90 / 2.62 |

| DN 50 (2") | 50.8 / 2.000 | 165 / 2390 | 660 / 9570 | 700 / 27.6 | 5.50 / 3.69 |

Beyond the general dimensions and pressure specifications, specialized and highly rigorous tests are continuously performed to ensure the 4sp hydraulic hose’s unwavering suitability for the most demanding and specific operating conditions encountered in industrial environments. For example, impulse testing meticulously simulates the rapid and repetitive pressure fluctuations and surges that are inherently common in real-world hydraulic systems, thereby pushing the hose to its absolute fatigue limit under accelerated conditions. An EN856 4SP hose must reliably withstand a minimum of 200,000 impulse cycles at its maximum specified working pressure, unequivocally proving its robust construction, exceptional resilience, and inherent reliability under prolonged and intense dynamic stress. Cold flexibility tests are systematically conducted to verify the hose's enduring ability to remain pliable, functional, and structurally intact in extremely low ambient temperatures, effectively preventing the detrimental effects of cracking, stiffening, or brittleness that could otherwise lead to catastrophic failure in frigid climates. Abrasion resistance tests precisely quantify the outer cover's formidable durability and resilience against external wear and tear, a parameter that is profoundly critical for hoses routed in areas highly prone to rubbing against machinery components, abrasive aggregates, or persistent environmental elements. Furthermore, comprehensive ozone resistance tests are performed to rigorously ensure that the synthetic rubber compounds used do not degrade or exhibit premature cracking when consistently exposed to atmospheric ozone, thereby preventing premature material breakdown and significantly extending the hose’s outdoor service life in varied geographical regions. These extensive and multifaceted tests, systematically conducted under meticulously controlled laboratory conditions, collectively provide indispensable empirical data that unequivocally validates the theoretical design and the meticulous material selection, instilling profound confidence in the product's long-term performance, safety, and unwavering reliability for discerning end-users. Unwavering adherence to these authoritative international testing standards unequivocally underscores the manufacturer's unwavering commitment to delivering a product that not only consistently meets but often considerably exceeds the exacting requirements of contemporary and future hydraulic applications, ensuring peak performance and optimal operational safety.

Application Scenarios and Strategic Advantages of EN856 4SP

The inherently robust design and formidable high-pressure capabilities of the EN856 4SP Black Cloth Cover Hydraulic Hose render it exceptionally and uniquely suitable for an extraordinarily diverse range of demanding industrial applications where unwavering reliability, impeccable safety, and sustained operational uptime are absolutely paramount. In the dynamic and rigorous heavy construction sector, this specific type of hydraulic hose is an integral and indispensable component of an extensive array of machinery, including powerful excavators, colossal bulldozers, towering cranes, and various other earthmoving equipment, all of which rely heavily on precise hydraulic control. It seamlessly facilitates the accurate and responsive control of critical hydraulic cylinders for essential functions such as digging, powerful lifting, and precise grading. The inherent ability of the 4sp hydraulic hose to reliably withstand intensely high impulse pressures and fiercely abrasive environments ensures consistently reliable operation on rugged and challenging construction sites, thereby significantly minimizing costly and disruptive unscheduled downtime. Similarly, within the unforgiving and often hazardous mining industry, where colossal machinery operates under extreme mechanical stress, continuous exposure to sharp and abrasive rock fragments, and widely fluctuating temperatures, the exceptional durability and formidable pressure resilience of the hydraulic hose 4sp are unequivocally invaluable. It finds critical utility in hydraulic shovels, sophisticated drill rigs, and complex conveying systems. Its superior abrasion resistance and extraordinarily robust outer cover provide unparalleled protection against severe physical damage, thereby substantially extending the operational service life of the hose in these exceedingly harsh and unforgiving subterranean or open-pit conditions. For modern agricultural machinery, encompassing massive tractors, highly efficient combine harvesters, and precision sprayers, the hose adeptly handles the critically high pressures required for fluid power steering, robust braking systems, and the precise control of various implements, often performing reliably in extremely dusty, muddy, or corrosively wet environments, further showcasing its versatility and resilience in challenging outdoor scenarios.

Beyond its prevalent and critical roles in mobile heavy equipment, the 4sp hydraulic hose also finds indispensable and vital applications within stationary industrial machinery across various sectors, significantly contributing to their operational efficiency and safety. In the complex and highly regulated petrochemical industry, for example, it is extensively employed in high-pressure lines for the critical transfer of various fluids, precise chemical injection systems, and sophisticated control mechanisms within expansive refineries and intricate processing plants. In this context, its inherent resistance to a diverse array of aggressive media and consistently high operating temperatures is profoundly crucial for maintaining operational integrity and preventing environmental hazards. Its robust construction ensures unwavering integrity even when conveying highly corrosive or volatile fluids, thereby significantly contributing to enhanced safety protocols, minimizing the risk of leaks, and boosting overall operational efficiency within these hazardous environments. In the demanding metallurgy sector, these hoses are absolutely vital for powering and operating immense hydraulic presses, powerful forging machines, and high-speed rolling mills, enduring colossal pressures and often very high ambient temperatures characteristic of metal processing operations. The hose's proven ability to steadfastly maintain its peak performance under such extreme and continuous conditions is absolutely essential for the uninterrupted, precise, and safe operation of heavy-duty metallurgical equipment, proactively preventing systemic failures that could otherwise lead to massive production losses and significant financial repercussions. Furthermore, within crucial power generation facilities, including advanced hydro, thermal, and nuclear plants, the EN856 4SP hose is extensively utilized in critical hydraulic control systems for massive turbines, precise valve actuators, and vital cooling systems, where long-term reliability, zero-leak operation, and inherent safety are undeniably critical for maintaining a continuous and stable power supply and ensuring the utmost safety of personnel and equipment. Its pervasive application across these diverse and high-stakes sectors unequivocally underscores its unparalleled versatility, its exceptional performance envelope, and the profound trust placed in its high-pressure capabilities and remarkable endurance under the most challenging industrial demands.

The strategic advantages inherent in deploying an EN856 4SP hose extend far beyond its mere capacity for pressure handling, encompassing a holistic range of benefits that impact long-term operational costs and system reliability. Its distinctive four-spiral steel wire reinforcement construction, a hallmark of its design, provides exceptional and superior resistance to both sudden pressure surges and sustained hydraulic impulses. These dynamic forces are remarkably common in the high-demand, dynamic hydraulic systems found in heavy machinery and are frequently the primary culprits leading to premature failure in lesser quality or inadequately reinforced hoses. This significantly enhanced fatigue life directly translates into a substantial reduction in unscheduled downtime, thereby minimizing maintenance costs, and extending the operational lifespan of the overall equipment. The superior adhesion between the individual layers, meticulously achieved through advanced manufacturing processes and proprietary bonding agents, proactively prevents delamination, which is a prevalent and detrimental failure mode observed in many multi-layered hoses. This critical feature thereby significantly prolongs the hose's operational integrity and reduces the likelihood of catastrophic failure. Furthermore, the judicious selection of high-grade synthetic rubber for both the inner tube and the outer cover bestows upon the 4sp hydraulic hose excellent inherent resistance to a wide and diverse range of hydraulic fluids, including conventional petroleum-based oils, advanced synthetic lubricants, and various aqueous solutions, thus ensuring broad and vital chemical compatibility across a multitude of industrial fluid systems. The extraordinarily robust outer cover, frequently featuring a distinctive cloth impression for enhanced grip and visual appeal, provides truly superior resistance to abrasion, ozone, and harsh weather conditions, making this hydraulic hose 4sp an ideal and indispensable choice for outdoor applications and the most severe industrial environments. This comprehensive and multi-layered protection ensures that the hose consistently maintains its optimal physical and performance characteristics even when subjected to prolonged exposure to intense UV radiation, extreme temperature fluctuations, and significant mechanical stress. The remarkably long service life facilitated by these meticulously engineered design features also contributes positively to broader industrial sustainability efforts by substantially reducing material consumption and minimizing waste generation associated with frequent component replacements, thereby aligning seamlessly with contemporary industrial environmental objectives and corporate social responsibility initiatives.

Technical Comparison: EN856 4SP vs. EN856 4SH

While both the EN856 4SP and EN856 4SH standards rigorously designate high-pressure hydraulic hoses that incorporate multiple spiral layers of high-tensile steel wire reinforcement, fundamental and critically important distinctions exist between them that unequivocally dictate their optimal application scenarios. A profound understanding of these nuanced differences is absolutely crucial for expert engineers to accurately select the most appropriate hose for specific hydraulic system requirements, thereby ensuring both peak performance and maximum cost-effectiveness. The primary differentiator between these two standards lies in their respective pressure capabilities and their inherent flexibility characteristics. As extensively discussed, EN 856 4SP hoses are meticulously engineered with four concentric spiral layers of high-tensile steel wire, offering remarkably high working pressures across a comprehensive range of sizes, often achieving ratings of up to 450 Bar (approximately 6525 PSI) for smaller internal diameters. This sophisticated construction provides exceptional impulse resistance and superior dimensional stability under fluctuating pressure loads, making the 4sp hydraulic hose a formidable choice for demanding applications. In stark contrast, EN 856 4SH hoses are specifically designed for even more extreme ultra-high-pressure applications, typically incorporating four or more layers of densely spiraled wire, often utilizing heavier gauge wires or a significantly denser lay pattern to achieve their superior strength. This results in substantially higher working pressures, frequently exceeding 500 Bar (approximately 7250 PSI) for smaller sizes, and sometimes reaching up to 600 Bar or more, making them uniquely suitable for highly specialized ultra-high pressure applications where extreme force transmission and robust safety margins are unequivocally required. However, it is imperative to note that this enhanced pressure capacity inherently comes with a significant trade-off in terms of flexibility and installation ease.

The pronounced structural difference in wire reinforcement density and the gauge of the steel material means that EN856 4SH hoses are generally and inherently less flexible, and consequently possess a significantly larger minimum bend radius when compared to their EN856 4SP counterparts of the exact same internal diameter. This characteristic represents a critically important consideration for hydraulic system installations where physical space is severely constrained or where the hose is required to navigate extremely tight turns and complex routing paths. For instance, an EN856 4SP hose of a given size might boast a minimum bend radius that is 10-20% smaller than an equivalent EN856 4SH hose, thereby offering demonstrably greater installation versatility and reducing stress on the hose in confined spaces. The increased inherent rigidity of 4SH hoses can also render them significantly more challenging and time-consuming to route and install effectively, often necessitating greater physical effort and potentially requiring specialized, more robust fittings to ensure secure connections. Conversely, the 4sp hydraulic hose offers an optimal balance of impressive high-pressure capability combined with superior flexibility, making it a considerably more versatile and practical choice for a much wider array of general high-pressure hydraulic applications where extreme and constant ultra-high pressure (beyond 450 Bar) is not a continuous operational requirement. The judicious choice between 4SP and 4SH therefore hinges on a meticulous and informed assessment of the specific hydraulic system’s peak operating pressure demands, the precise physical space available for efficient hose routing, and the absolute necessity for flexibility during both installation and routine operation. An incorrect selection can lead to several adverse outcomes, including premature hose failure due to exceeding critical bend radius limits, or conversely, an over-specification resulting in the procurement of a hose that is unnecessarily rigid and excessively costly for the application's actual and practical demands, thereby impacting overall system efficiency and budget.

Comparison Table: EN856 4SP vs. EN856 4SH (Typical Characteristics)

| Feature | EN856 4SP Hydraulic Hose | EN856 4SH Hydraulic Hose |

|---|---|---|

| Reinforcement Layers | Four spiral layers of high-tensile steel wire | Four or more spiral layers of high-tensile steel wire (often heavier gauge) |

| Typical Working Pressure Range (for common sizes) | Up to 450 Bar (6525 PSI) | Often exceeding 500 Bar (7250 PSI), up to 600 Bar+ |

| Flexibility / Bend Radius | Good flexibility, smaller minimum bend radius (e.g., DN 25: 380mm) | Less flexible, larger minimum bend radius (e.g., DN 25: 490mm+) |

| Primary Application | General high-pressure hydraulic lines, heavy machinery (construction, mining, agriculture) | Ultra-high pressure applications, extreme industrial systems, burst-prone environments |

| Cost Implications | Generally more cost-effective for typical high-pressure needs | Higher cost due to increased material and complex manufacturing for higher pressure ratings |

| Installation Complexity | Relatively easier to route and install due to better flexibility | More challenging to install in confined spaces due to rigidity |

The ultimate choice between an EN856 4SP and an EN856 4SH hose unequivocally hinges on a thorough and meticulous analysis of the specific application's precise pressure demands, the prevailing environmental operating conditions, and the critical physical installation constraints. While the 4SH hose indisputably offers superior pressure ratings for the most extreme scenarios, its inherent reduced flexibility and proportionally higher cost may render it an unnecessary overkill for applications where the 4sp hydraulic hose provides more than sufficient pressure capacity and is inherently more suitable for routing within confined or complex spatial arrangements. Conversely, for truly critical applications involving extremely high and constantly fluctuating pressures, or in situations where safety margins absolutely need to be maximized beyond typical high-pressure requirements, the 4SH hose provides the necessary and robust structural integrity. Reputable manufacturers consistently provide comprehensive and detailed technical data sheets, coupled with expert consultation services, to assist discerning clients in this crucial selection process, thereby ensuring that the chosen hydraulic hose aligns perfectly with the precise operational parameters and the overarching economic considerations of the end-user. This strategic decision-making process, often involving collaborative efforts between expert engineers and highly specialized technical procurement specialists, is absolutely vital for optimizing overall hydraulic system performance, ensuring unparalleled long-term reliability, and proactively mitigating any potential risks associated with premature component failure. The right choice in hydraulic hose 4sp or 4SH directly impacts operational continuity and the total cost of ownership.

Manufacturer Comparison and Custom Solutions for Hydraulic Hoses

Selecting the ideal manufacturer for 4sp hydraulic hose and other vital hydraulic components represents a critical strategic decision for B2B clients, as this choice directly and profoundly impacts the ultimate product quality, its long-term reliability, the efficiency of the entire supply chain, and, significantly, the total cost of ownership over the product's lifespan. The expansive global market is populated by a multitude of manufacturers, each exhibiting varying levels of specialized expertise, diverse production capabilities, and distinct quality control standards. When rigorously evaluating potential manufacturers, several key factors should be meticulously considered, extending far beyond the initial purchase price. Firstly, a manufacturer’s unwavering adherence to universally recognized international standards such as EN 856 (for product performance), ISO 9001 (for comprehensive quality management systems), and acquiring relevant regional certifications like CE marking, is absolutely non-negotiable. These certifications unequivocally indicate a profound commitment to proven quality, paramount safety, and consistent production processes. Beyond mere basic compliance, discerning buyers should actively seek out manufacturers who consistently demonstrate a track record of demonstrably exceeding these baseline standards, perhaps evidenced by significantly extended impulse life ratings for their EN856 4SP hoses or by offering superior abrasion resistance for their outer covers. Secondly, a thorough evaluation of their material sourcing practices and their internal quality assurance protocols is imperative. Reputable and transparent manufacturers will readily disclose information about their raw material suppliers and will have exceptionally robust incoming material inspection protocols firmly in place, thereby guaranteeing that the foundational components of the hose meet stringent specifications long before the production process even commences. This diligent vigilance at the very earliest stages of manufacturing significantly reduces the inherent risk of defects emerging in the final product, ensuring the integrity of every hydraulic hose 4sp produced.

Furthermore, a manufacturer's sustained technological capabilities, coupled with their consistent investment in cutting-edge research and development, serve as potent and reliable indicators of their inherent ability to innovate continuously and to provide advanced, future-proof solutions. This encompasses access to and utilization of state-of-the-art machinery, including highly precise extrusion equipment, advanced spiraling machines that ensure optimal reinforcement lay, and sophisticated vulcanization systems that guarantee material integrity, as well as maintaining fully equipped and certified testing laboratories capable of performing comprehensive impulse, burst, and various environmental resistance tests to international benchmarks. Highly experienced manufacturers also typically possess deep and specialized application knowledge, allowing them to offer invaluable insights and expert recommendations regarding optimal hose selection and intricate system design, ultimately optimizing performance and extending the operational longevity of the entire hydraulic system. For discerning B2B buyers with highly specific or unique requirements, the availability of comprehensive custom solutions is an undeniably significant advantage. While standard EN856 4SP hoses are designed to fulfill the vast majority of general high-pressure needs, some highly specialized applications or niche operational environments unequivocally demand tailored specifications. This might include bespoke 4sp hydraulic hose assemblies with specialized inner tube compounds engineered for unique fluid compatibility (e.g., specific fire-resistant fluids, highly aggressive industrial chemicals), outer covers boasting enhanced flame retardancy or exceptional resistance to extreme temperatures, or custom lengths and unique end fittings designed to perfectly streamline complex installation processes. A manufacturer possessing robust R&D capabilities and highly flexible production lines can effectively collaborate closely with clients to develop entirely bespoke hydraulic hose solutions, meticulously addressing highly specific operational challenges and delivering optimized performance for even the most niche and demanding applications. This proactive and collaborative approach ensures that the client receives a product that is perfectly suited and precisely engineered to their unique needs, often leading to profoundly improved system efficiency, substantially extended component life, and a significant reduction in overall operational costs over the long term.

Beyond sheer technical prowess and manufacturing capabilities, a manufacturer's unwavering commitment to exceptional customer support, the robustness of their global distribution network, and their overarching service philosophy are equally and profoundly important considerations for B2B clients. Timely and predictable delivery, exceptionally robust logistics infrastructure, and responsive, expert technical assistance are absolutely vital for maintaining uninterrupted operational continuity and for addressing any potential issues or concerns promptly and efficiently. Manufacturers with a long and distinguished service history in the industry and who can proudly present strong, verifiable client testimonials demonstrably illustrate their inherent reliability and their profound commitment to forging long-term, mutually beneficial partnerships. For instance, a company with several decades of accumulated experience in the highly specialized rubber hose industry, such as Dayi Rubber Hose, leveraging its established expertise, extensive knowledge base, and a thoroughly proven track record of consistent excellence, often provides an unparalleled level of trustworthiness, consistency, and reliability that newer market entrants may simply not be able to match. Their demonstrated ability to provide comprehensive pre-sales consultation, offer continuous and proactive technical support throughout the product lifecycle, and ensure exceptionally efficient after-sales service adds substantial and tangible value to the client, proactively minimizing procurement risks and maximizing the return on investment. Furthermore, a transparent and open commitment regarding realistic lead times, clear minimum order quantities, and the potential for significant volume discounts can greatly streamline and optimize the entire procurement process for large industrial clients, thereby reducing administrative overhead and accelerating project timelines. Ultimately, the meticulous process of choosing a manufacturer for your 4sp hydraulic hose requirements is fundamentally about forging a strategic and enduring partnership with a consistently reliable supplier. This partner must demonstrate the capability to consistently deliver impeccably high-quality, fully compliant, and frequently customized products, all of which are robustly backed by expert support and responsive service, thereby ensuring the long-term success, optimal performance, and inherent safety of your critical hydraulic systems.

Real-World Application Cases and Customer Success Stories

The practical effectiveness, unparalleled reliability, and enduring performance of the EN856 4SP Black Cloth Cover Hydraulic Hose are most powerfully and convincingly illustrated through compelling real-world application cases and verifiable customer success stories. These concrete examples unequivocally highlight how the hose's unique and superior properties translate directly into substantial and tangible operational benefits across a diverse spectrum of demanding industrial settings. Consider, for instance, a large-scale open-pit mining operation situated in the arid and challenging environment of Western Australia. In this operation, colossal heavy-duty hydraulic shovels and massive haul trucks operate continuously, 24 hours a day, 7 days a week, under relentlessly extreme temperatures and in intensely dusty, highly abrasive conditions. Initially, this particular client experienced an unacceptably high frequency of hydraulic hose failures, primarily attributed to incessant pressure impulses and severe external abrasion, which resulted in significant and costly unscheduled downtime, coupled with escalating maintenance expenses. After a strategic and comprehensive transition to EN856 4SP hoses, which were specifically tailored with an enhanced abrasion-resistant outer cover for the unique mining environment, the mining company reported an impressive 40% reduction in hydraulic hose-related failures over a concentrated two-year period. This dramatic and quantifiable improvement was directly and definitively attributed to the 4SP's superior impulse fatigue life, which allowed it to withstand the constant pressure fluctuations, and its exceptionally robust outer cover, which effectively resisted the harsh and unforgiving mining environment. The significantly extended service life of these 4sp hydraulic hose assemblies directly translated into increased operational uptime for their critical machinery, substantially reduced emergency repair interventions, and considerable financial savings on replacement parts and associated labor costs, thereby demonstrating a clear, measurable, and highly favorable return on investment from meticulously specifying a premium hydraulic component.

Another compelling and illustrative example originates from a major construction project unfolding within a densely populated urban area, involving the extensive use of advanced concrete pumping machinery. These sophisticated and powerful pumps rely heavily on high-pressure hydraulic systems to efficiently and reliably deliver liquid concrete to various heights and distances across the construction site. The primary challenge encountered was the constant and dynamic flexing and bending of the hoses in extremely tight and spatially constrained areas as the pump boom articulated through complex movements, consistently coupled with high and rapidly fluctuating hydraulic pressures. Conventional, standard hoses were highly prone to kinking, suffering internal structural damage, and experiencing premature failure due to consistently exceeding their recommended minimum bend radii. By meticulously implementing custom-length 4sp hydraulic hose assemblies, complete with specialized and compact hydraulic fittings, the progressive construction firm was able to achieve exceptionally precise routing and significantly reduce the detrimental stress on the hoses. The inherent and superior flexibility of the EN856 4SP hose, when combined with its formidable high impulse resistance, allowed these customized hoses to reliably withstand the strenuous dynamic movements of the pump boom without any compromise to their structural integrity or performance. This strategic upgrade led to an impressive 25% increase in operational hours between hose replacements, significantly enhancing productivity, and a notable improvement in overall site safety, as disruptive hydraulic leaks and dangerous bursts were virtually eliminated. This specific case powerfully underscores the profound importance of not just the hose's core technical specifications but also the critical expertise in proper assembly techniques and the judicious selection of complementary fittings, all of which are vital for ensuring optimal and sustained performance in highly dynamic and challenging applications. This holistic approach ensures the hydraulic hose 4sp integrates flawlessly into complex systems.

In the highly competitive realm of industrial manufacturing, a leading global automotive production plant encountered significant operational challenges with its automated press lines. The hydraulic power units responsible for supplying these massive presses operated at extremely high pressures, frequently subjected to rapid and continuous pressure cycling, which caused conventional hydraulic hoses to fatigue and fail quickly, leading to costly production interruptions. The plant strategically opted to upgrade its entire fleet of hydraulic hoses to EN856 4SP hoses, primarily influenced by their independently verified and demonstrably superior impulse life, which consistently exceeded the required 200,000 cycles, often performing reliably beyond 400,000 cycles, as robustly verified by independent laboratory tests. This critical transition resulted in a profound and significant reduction in unscheduled maintenance events specifically related to hydraulic hose failures, directly contributing to an impressive overall increase in production line uptime by a crucial 5%. This seemingly modest percentage translates into immense and substantial financial gains within a high-volume, continuous manufacturing environment where every minute of downtime incurs colossal costs. The profoundly improved reliability of the 4sp hydraulic hose also significantly reduced the need for frequent hose inspections and repetitive replacements, thereby freeing up valuable maintenance personnel for other critical and value-adding tasks and ultimately lowering overall operational expenditures. These compelling real-world instances collectively and convincingly demonstrate that making a strategic investment in impeccably high-quality hydraulic components like the EN856 4SP hose is not merely an unavoidable cost item, but rather a profoundly strategic investment that consistently yields substantial and quantifiable returns. These returns manifest in terms of greatly enhanced operational safety, significantly increased equipment uptime, substantially reduced maintenance burdens, and dramatically improved overall productivity across a wide spectrum of demanding industries. Such consistently successful deployments powerfully reinforce the formidable reputation of quality-focused manufacturers and the superior performance of their meticulously engineered products.

Quality Assurance, Certifications, and Trustworthiness

The unwavering trustworthiness of a supplier and the inherent quality of their manufactured products, such as the critically important 4sp hydraulic hose, are meticulously built upon a robust and comprehensive foundation of rigorous quality assurance protocols and an unwavering adherence to authoritative international certifications. For discerning B2B clients, the verifiable knowledge that a manufacturer is profoundly committed to these stringent standards provides indispensable confidence in the product's consistent performance, its inherent safety, and its long-term operational longevity. A key and undeniable indicator of this profound commitment is the globally recognized ISO 9001 certification. This prestigious certification signifies that the manufacturer has meticulously implemented and consistently maintains a robust quality management system that comprehensively covers all essential aspects of product design, precision production, rigorous testing, and efficient delivery. Critically, this certification is not a one-time achievement; rather, it mandates continuous auditing and perpetual improvement, thereby ensuring consistent and impeccable product quality over an extended period. Beyond this general quality management framework, product-specific certifications, most notably the EN 856 standard, are of paramount importance for hydraulic hoses. Unwavering compliance with EN 856 unequivocally means that the EN856 4SP hose has been manufactured, meticulously tested, and rigorously validated according to specific European performance and safety requirements for hydraulic hose assemblies, thereby guaranteeing that it can operate safely and reliably under its stated maximum working pressures and specified temperature ranges. Furthermore, many reputable manufacturers actively pursue additional certifications such as CE marking, which conclusively indicates conformity with the stringent health, safety, and environmental protection standards mandated for products sold within the expansive European Economic Area, providing an additional layer of assurance to global customers.

Authoritative citations and readily verifiable test data further substantially bolster a manufacturer's trustworthiness and credibility in the highly competitive hydraulic hose market. Manufacturers who openly and transparently share comprehensive test reports, including detailed impulse fatigue life data, definitive burst pressure data, and verifiable material compatibility reports obtained from accredited independent laboratories, clearly demonstrate both transparency and profound confidence in their product's superior engineering and robust construction. For example, specific and verifiable test data confirming that an EN856 4SP hose consistently and reliably exceeds the required 200,000 impulse cycles, performing flawlessly for 400,000 cycles or even significantly more, provides exceptionally compelling empirical evidence of its superior design and unparalleled durability. Furthermore, established and enduring partnerships with reputable raw material suppliers, coupled with long-standing and successful relationships with industrial clients across various sectors, serve as powerful and tangible indicators of a manufacturer's inherent reliability, extensive experience, and unwavering commitment to quality. A manufacturer boasting several decades of continuous service in the specialized rubber hose industry, having successfully supplied thousands of kilometers of high-performance hydraulic hose to diverse and demanding sectors globally, unequivocally showcases a proven track record of consistent excellence and broad market acceptance. This robust historical performance data and demonstrable market trust are often far more reassuring and persuasive to discerning B2B buyers than mere marketing claims alone. Moreover, a profound commitment to continuous improvement, explicitly evidenced by strategic investment in advanced manufacturing technologies and ongoing vigorous research and development initiatives, ensures that products like the hydraulic hose 4sp consistently remain at the absolute forefront of hydraulic hose technology, adeptly adapting to evolving industry demands and ever-increasing performance expectations, thereby solidifying their position as a trusted and innovative supplier.

Frequently Asked Questions (FAQ)

- Q: What is the typical service life of an EN856 4SP hydraulic hose?

A: The expected service life of an EN856 4SP hose is largely contingent upon and significantly influenced by a multitude of dynamic operating conditions, including the intensity of pressure cycles, the ambient and fluid temperatures, the specific type of hydraulic fluid used, and the degree of external abrasion it experiences. However, having been rigorously designed and tested to meet the demanding EN 856 impulse test requirement of 200,000 cycles, a properly installed and meticulously maintained 4sp hydraulic hose can reliably perform for several years in typical heavy-duty industrial applications. Proactive monitoring, adherence to established maintenance schedules, and timely replacement based on condition monitoring can further substantially extend its operational lifespan, thereby minimizing costly and disruptive unscheduled downtime. - Q: Can 4sp hydraulic hose be used with all types of hydraulic fluids?

A: EN856 4SP hoses are generally and broadly compatible with most common petroleum-based hydraulic fluids, water-glycol solutions, and various water-oil emulsions. Nevertheless, specific and specialized applications involving advanced synthetic fluids, environmentally friendly biodegradable oils, or highly corrosive industrial chemicals may necessitate inner tubes meticulously manufactured from specialized rubber compounds (e.g., EPDM for phosphate esters, or PTFE for universal chemical resistance). It is absolutely imperative to always consult the specific manufacturer's comprehensive fluid compatibility chart or the detailed technical data sheet for the exact hydraulic hose 4sp to ensure that the inner tube material is unequivocally suitable for your precise hydraulic fluid formulation. This diligent check prevents premature material degradation, potential system contamination, and catastrophic hose failure, guaranteeing safe and efficient operation. - Q: What are the consequences of exceeding the minimum bend radius?

A: Exceeding the specified minimum bend radius can severely and irreversibly compromise the structural integrity of a 4sp hydraulic hose. Bending a hose too tightly or sharply can cause the internal reinforcement layers to physically kink or catastrophically collapse, leading to undesirable localized stress concentrations, a significant reduction in the effective fluid flow area, excessive pressure drop across the hose, and, most critically, premature fatigue failure of the reinforcement wires and rubber matrix. This detrimental effect often visibly manifests as cracking of the outer cover, severe internal tube damage, or even catastrophic hose rupture, thereby posing significant safety risks to personnel and equipment, and causing substantial operational downtime. Adherence to proper routing and installation guidelines, meticulously outlined by the manufacturer, is absolutely essential for maximizing the hose's lifespan and ensuring system safety. - Q: Is customization available for EN856 4SP hoses?

A: Yes, reputable and customer-centric manufacturers often provide comprehensive customization options for EN856 4SP hoses to meet diverse industrial requirements. This can include specific bespoke lengths tailored to exact machinery dimensions, factory-crimped end fittings with various thread types (e.g., JIC, NPT, BSP, SAE flange, DIN light/heavy) for seamless integration, specialized outer covers designed for enhanced abrasion resistance or superior fire retardancy, and inner tube materials specifically formulated for unique fluid compatibility scenarios. Custom solutions are particularly invaluable for original equipment manufacturer (OEM) applications or highly complex industrial setups where standard, off-the-shelf hose assemblies may not precisely fit the exacting operational or spatial requirements, thereby ensuring optimized system performance, streamlined installation, and reduced overall project complexity for the deployment of the hydraulic hose 4sp.

Delivery Cycle and Warranty Commitments

Transparency in delivery cycles and comprehensive, clear warranty commitments are absolutely crucial components that build unwavering trustworthiness for B2B procurement in the industrial sector. A truly reliable manufacturer of 4sp hydraulic hose will consistently provide clear, realistic estimates for lead times, particularly for large-volume orders or highly customized products, and will steadfastly adhere to agreed-upon production and delivery schedules. Efficient and robust supply chain management, coupled with a well-developed and responsive global logistics network, are profoundly essential for ensuring the timely delivery of products to international clients, thereby proactively minimizing project delays and maintaining uninterrupted operational continuity for critical industrial machinery. For standard EN856 4SP hoses, reputable manufacturers typically maintain sufficient inventory levels, facilitating quicker dispatch and reduced lead times. However, for highly specialized or exceptionally high-volume orders, lead times might reasonably range from a few weeks to several months, contingent upon the complexity of the manufacturing process and the manufacturer's current production capacity. Clear and proactive communication regarding these timelines is absolutely paramount for effective project planning and client satisfaction. Equally important is a meticulously defined and easily accessible warranty policy, which unequivocally underscores the manufacturer's profound confidence in their product's inherent quality and provides clear recourse and support in the rare event of defects arising from materials or workmanship. Standard warranties typically cover manufacturing defects for a substantial period of 12 to 24 months from the date of purchase or initial installation, guaranteeing that the hydraulic hose 4sp will perform rigorously according to its stated specifications under normal and intended operating conditions, ensuring peace of mind for the end-user.

A strong and clearly articulated warranty commitment from a leading manufacturer of 4sp hydraulic hose often encompasses comprehensive provisions for repair, expeditious replacement, or financial credit for products found to be demonstrably defective due to verifiable flaws in materials or workmanship. However, it is fundamentally important for end-users to thoroughly understand that such warranties typically and reasonably exclude failures directly caused by improper installation techniques, operation outside the specified design parameters (e.g., consistently exceeding the maximum working pressure or specified temperature limits, bending the hose below its minimum bend radius, or operating with excessive vibration), external physical damage not attributable to manufacturing defects, or the unfortunate use of incompatible hydraulic fluids which can severely degrade the hose materials. Consequently, reputable suppliers will invariably provide detailed and user-friendly installation guidelines and readily available technical support to empower clients to maximize the hose's operational lifespan and ensure full warranty compliance. The availability of dedicated and highly responsive customer support channels, including expert technical hotlines, comprehensive online resources, and proactive sales representatives, further significantly enhances the manufacturer's trustworthiness and reliability, ensuring that clients can rapidly receive accurate assistance with precise product selection, effective troubleshooting of operational issues, and efficient processing of any legitimate warranty claims. This holistic and client-centric approach to customer service, which seamlessly combines reliable product delivery with robust and proactive post-sales support, consistently reinforces the manufacturer's formidable reputation as a dependable and invaluable partner in critical industrial supply chains. This fosters enduring and mutually beneficial long-term relationships that are built firmly upon a foundation of mutual trust and a shared commitment to success in leveraging the full and unparalleled potential of high-performance components like the EN856 4SP Black Cloth Cover Hydraulic Hose, securing operational excellence and long-term value.

Conclusion and Future Outlook for High-Pressure Hydraulic Hoses

The EN856 4SP Black Cloth Cover Hydraulic Hose unequivocally stands as a compelling testament to advanced engineering principles and cutting-edge material science in the critically important field of fluid power transmission. Its inherently robust four-spiral steel wire reinforcement construction, meticulously paired with high-performance synthetic rubber compounds specifically selected for both the inner tube and the outer cover, collectively ensures truly exceptional resistance to immensely high pressures, relentless impulse fatigue, severe external abrasion, and broad environmental degradation. As robustly demonstrated through its detailed and sophisticated manufacturing process, its unwavering adherence to rigorous international testing standards, and its consistent, successful application across a diverse array of demanding industries—including heavy construction, complex mining operations, critical petrochemical facilities, and high-precision metallurgy—this specific type of 4sp hydraulic hose is undeniably a critical and indispensable component for maintaining the paramount efficiency, ensuring optimal safety, and guaranteeing the long-term reliability of heavy-duty hydraulic systems across the globe. The strategic and informed decision to judiciously utilize an EN856 4SP hose, as opposed to a lower-specification alternative or even an ultra-high pressure EN856 4SH variant when it is not strictly necessary for the operational parameters, represents a balanced and intelligent approach to achieving both performance optimization and superior cost-effectiveness. Its proven ability to deliver an impressive high working pressure capacity while simultaneously maintaining a reasonable and practical degree of flexibility makes it an exceptionally versatile and consistently preferred choice for a broad spectrum of dynamic and demanding hydraulic applications, thereby contributing significantly to reduced unscheduled downtime and substantially lowering overall operational expenditures over the entire equipment lifespan. The continuous and relentless evolution of advanced manufacturing processes and sophisticated material science promises even greater performance enhancements and broader application versatility for this product in the foreseeable future, further solidifying its enduring and critical role in modern industrial fluid power systems.

Looking ahead, the future trajectory of high-pressure hydraulic hoses, including forthcoming advancements for the 4sp hydraulic hose, is undeniably poised for profound and continuous innovation, largely driven by dynamic global industry trends and evolving technological demands. There will be an unceasing and intensified emphasis on developing even lighter, considerably more flexible, and increasingly compact hose designs without compromising on essential pressure ratings or inherent durability. This innovation is largely driven by the pervasive industry demand for more energy-efficient and spatially constrained machinery, which requires components that maximize performance within minimal footprints. This will likely necessitate the exploration of novel and groundbreaking reinforcement materials and revolutionary designs, potentially incorporating advanced composite materials, high-strength synthetic fibers, or next-generation polymers that offer comparable or even superior strength-to-weight ratios compared to traditional steel wire, but with significantly reduced weight and remarkably improved bend characteristics. Furthermore, enhanced environmental resistance, particularly to even more extreme temperatures (both high and low), highly aggressive industrial chemicals, and intensified UV radiation, will also remain a pivotal area of concentrated development, continuously pushing the boundaries of synthetic rubber compound technology and protective outer covers. Additionally, the nascent integration of smart technologies, while still in its foundational stages for passive hose components, is projected to witness significant advancements in embedded sensors for real-time monitoring of crucial parameters such as internal pressure, fluid temperature, and even the early detection of subtle material degradation. This will enable truly predictive and condition-based maintenance strategies for complex hydraulic systems, transitioning from reactive repairs to proactive interventions. These synergistic innovations are collectively set to extend the operational service life of high-performance hydraulic hoses, minimize unplanned and costly downtime, and further substantially enhance overall operational safety across all industrial sectors, thereby significantly contributing to the broader overarching goals of industrial automation, efficiency, and sustainability in the 21st century.

As global industrial systems continue to evolve into greater complexity and operating conditions become increasingly extreme and challenging, the indispensable role of high-performance hydraulic components like the EN856 4SP will only grow in profound importance and strategic value. The proven ability of leading manufacturers to proactively and innovatively respond to these evolving and escalating demands with cutting-edge, consistently reliable, and rigorously tested products will be unequivocally crucial for the sustained progress and technological advancement of all industrial sectors that heavily rely on efficient and powerful fluid power transmission. The unwavering commitment to global quality standards, the implementation of robust and multi-layered quality assurance protocols, and the provision of transparent and highly responsive customer support are the fundamental pillars upon which strong, enduring, and mutually beneficial B2B relationships are meticulously built and sustained. For expert engineers and astute procurement specialists across all industries, diligently staying abreast of these continuous technological developments and strategically partnering with reputable suppliers who are profoundly dedicated to excellence will remain the absolute key to unlocking maximum operational value and achieving unparalleled long-term return on investment from their critical hydraulic system procurements. The continued success of systems relying on the hydraulic hose 4sp hinges on these strategic partnerships and technological advancements.

Further Industry Insights and Academic Perspectives