335345435

Nov . 04, 2024 19:13 Back to list

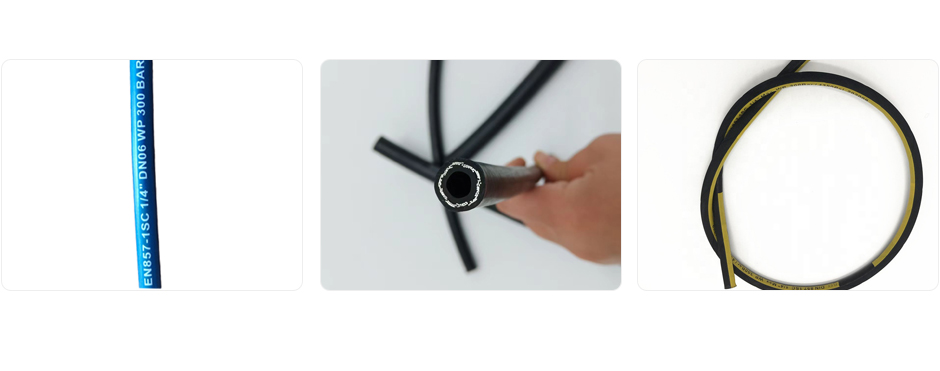

wrapped cover steel wire braided hydraulic hose factories

Introduction to Wrapped Cover Steel Wire Braided Hydraulic Hose Factories

Hydraulic systems are an integral part of various industries, from construction and manufacturing to agriculture and automotive. One of the essential components of these systems is the hydraulic hose, which is responsible for transferring hydraulic fluid under high pressure. Among the different types of hydraulic hoses, wrapped cover steel wire braided hydraulic hoses are known for their durability and strength. This article explores the significance of factories specializing in the production of these hoses, their processes, and the benefits they offer.

The Manufacturing Process

Factories that produce wrapped cover steel wire braided hydraulic hoses employ advanced manufacturing techniques to ensure the highest quality products. The manufacturing process begins with selecting premium raw materials, including high-strength synthetic rubber and steel wires. The steel wire is braided around the rubber core, providing exceptional tensile strength and resistance to pressure. The outer layer of the hose is usually wrapped with an additional protective cover designed to withstand external abrasions and environmental factors.

Quality control is a crucial aspect of the manufacturing process. Factories often implement stringent testing procedures to ensure that each hose meets industry standards and can withstand the pressures it will encounter in real-world applications. These tests include pressure testing, burst testing, and abrasion testing.

wrapped cover steel wire braided hydraulic hose factories

Benefits of Steel Wire Braided Hoses

Wrapped cover steel wire braided hydraulic hoses offer numerous advantages. Their design allows them to handle high pressure, making them suitable for demanding hydraulic applications. The steel wire braiding provides added resistance to crushing and elongation, ensuring longevity and reliability.

Moreover, the protective wrapped cover not only enhances the hose’s durability but also offers resistance against oil, fuel, and other chemicals, making it capable of performing in harsh environments. These hoses are also flexible, allowing for easier installation in tight spaces, which is often a critical consideration in machinery design.

Conclusion

In conclusion, the factories that produce wrapped cover steel wire braided hydraulic hoses play a vital role in supplying industries with essential components that ensure the efficiency and reliability of hydraulic systems. The combination of high-quality materials, advanced manufacturing processes, and strict quality control measures results in hoses that not only meet but exceed industry standards. As technology advances and industries evolve, these factories will continue to adapt and innovate, ensuring that they provide the best products to meet the ever-increasing demands of the market.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025