335345435

Dec . 03, 2024 19:02 Back to list

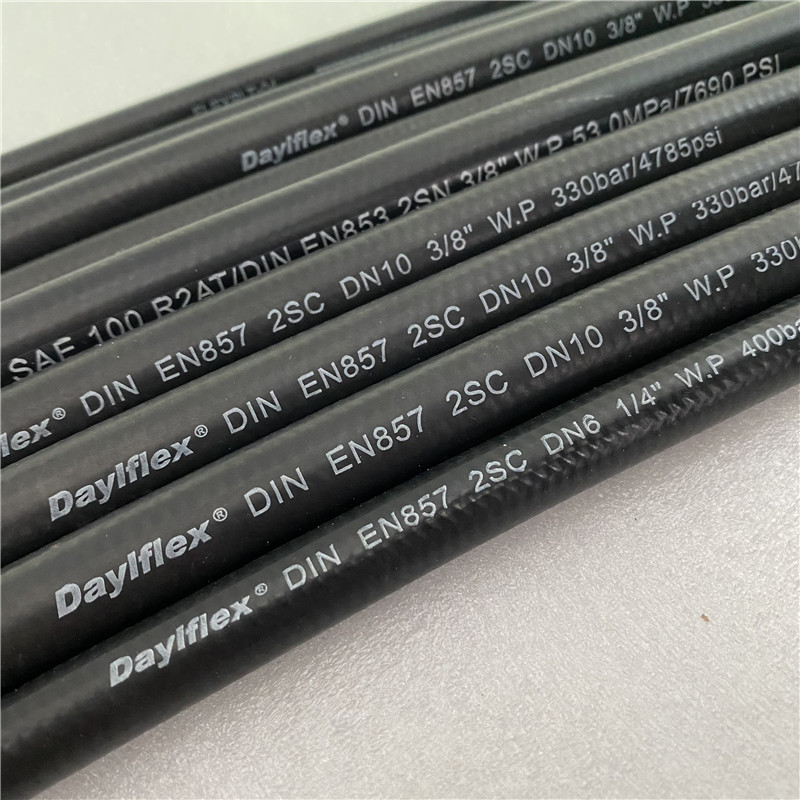

wrapped cover high pressure hydraulic hose supplier

The Importance of Wrapped Cover High-Pressure Hydraulic Hoses A Focus on Reliable Suppliers

In various industrial applications, the need for high-pressure hydraulic hoses is paramount. Whether it's in construction, manufacturing, or automotive industries, the reliability of hydraulic systems is crucial for smooth operations. Among the various types of hydraulic hoses available, wrapped cover high-pressure hydraulic hoses stand out due to their durability and performance attributes. This article delves into the significance of these hoses and highlights the role of reliable suppliers in ensuring quality.

What are Wrapped Cover High-Pressure Hydraulic Hoses?

Wrapped cover high-pressure hydraulic hoses are engineered to withstand extreme conditions. The term wrapped cover refers to an additional layer of protective material wrapped around the hose, enhancing its structural integrity. These hoses are typically constructed with a synthetic rubber inner layer that carries the hydraulic fluid, reinforced with high-tensile steel wire and covered with a wrapped protective layer made from rubber or thermoplastic materials. This construction makes them resistant to abrasion, weather, and various chemicals, making them ideal for challenging environments.

Key Benefits of Wrapped Cover High-Pressure Hydraulic Hoses

1. Enhanced Durability The wrapping provides an extra layer of protection, increasing the hose's resistance to wear and damage. This durability extends the hose's lifespan, reducing the frequency of replacements and maintenance.

2. High Pressure and Temperature Resistance These hoses can handle high-pressure applications, often exceeding 6,000 PSI. Additionally, they can function effectively in high-temperature environments, making them suitable for various hydraulic systems.

3. Flexibility and Maneuverability Wrapped cover hoses are designed to be flexible, allowing for easier installation and routing through tight spaces. This flexibility helps to minimize the risk of kinking, which can lead to reduced performance or rupture.

4. Safety Features The reinforced structure and improved resilience of wrapped cover hoses contribute to overall system safety. A failure in hydraulic systems can lead to catastrophic results, and high-quality hoses mitigate such risks.

5. Wide Application Range These hoses can be used across multiple industries, including agriculture, construction, and mining, highlighting their versatility.

wrapped cover high pressure hydraulic hose supplier

Choosing a Reliable Supplier

When it comes to acquiring wrapped cover high-pressure hydraulic hoses, selecting a credible supplier is crucial. The quality of the hoses directly affects the performance of hydraulic systems, making the choice of supplier an important decision.

1. Quality Assurance Look for suppliers that adhere to industry standards and quality certification processes. ISO certifications and compliance with SAE (Society of Automotive Engineers) standards are indicators of a supplier’s commitment to quality.

2. Product Range A good supplier should offer a broad range of hydraulic hoses with different specifications and applications. This variety ensures that you can find the right hose for your specific needs.

3. Technical Support and Expertise Reliable suppliers often have knowledgeable staff who can provide technical support and guidance. They can help you select the right hose for your application and offer solutions for any specific challenges you may face.

4. Customer Reviews and Reputation Researching customer feedback and testimonials can give you insight into a supplier's reliability and service quality. A positive track record in the industry is often a good sign.

5. After-Sales Support Excellent after-sales support is essential for maintaining long-term partnerships. Suppliers that provide warranty options and responsive customer service can greatly enhance your experience.

Conclusion

In conclusion, wrapped cover high-pressure hydraulic hoses are indispensable components in various industrial applications, offering durability, flexibility, and safety features that help ensure optimal hydraulic system performance. The role of a reliable supplier in delivering high-quality hoses cannot be overstated. By choosing the right supplier, businesses can enhance their operational efficiency, reduce downtime, and ensure safety in their hydraulic systems. Investing time in selecting a reputable supplier will ultimately lead to better performance and reliability in the long run.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025