335345435

Sep . 07, 2024 23:20 Back to list

wrapped surface hydraulic hose

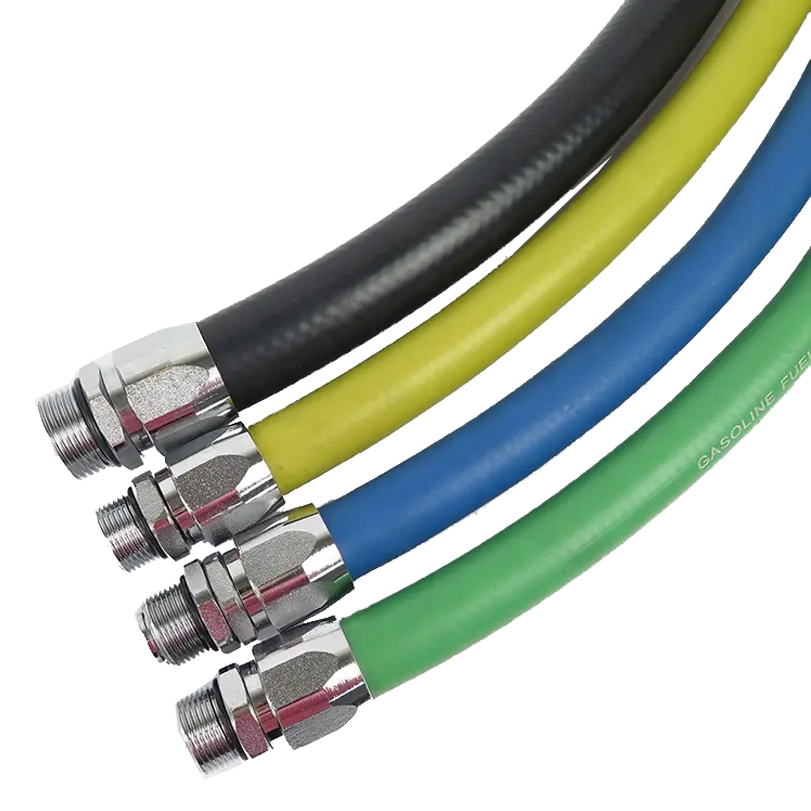

Understanding Wrapped Surface Hydraulic Hoses

Hydraulic hoses are critical components in various industrial applications, serving as conduits for hydraulic fluid to transmit power. Among the various types of hydraulic hoses available, wrapped surface hydraulic hoses are particularly noteworthy due to their robust construction and superior performance characteristics.

Wrapped surface hydraulic hoses are designed with multiple layers that include a reinforced inner tube, one or more layers of braiding or spiraling wire, and an outer cover that often features a wrapped design. This wrapping not only adds to the hose's durability but also enhances its resistance to abrasion and external damage. The wrapping is typically made of materials such as rubber or synthetic compounds, which can withstand harsh environments while maintaining flexibility and strength.

One of the primary advantages of wrapped surface hydraulic hoses is their exceptional pressure handling capabilities. These hoses can operate at high pressures, making them suitable for demanding applications such as construction, mining, and manufacturing. The wrapping provides additional structural integrity, ensuring that the hose maintains its shape and function under stress. This is particularly important in applications where hoses are frequently moved or subjected to dynamic forces.

wrapped surface hydraulic hose

In addition to pressure resistance, wrapped surface hydraulic hoses offer improved resistance to environmental factors

. These hoses are often rated for exposure to oil, water, and various chemicals, which are common in industrial settings. Furthermore, the outer wrapping helps protect the inner layers from UV radiation, ozone, and other degrading elements, thus extending the hose's lifespan.Installation and maintenance of wrapped surface hydraulic hoses are relatively straightforward, but attention to detail is crucial to ensure optimal performance. Proper fitting and connection are essential, as leaks can lead to not only efficiency losses but also safety hazards. Regular inspections for signs of wear or damage can help identify potential issues before they lead to hose failure.

When selecting a wrapped surface hydraulic hose, it is essential to consider factors such as the hose's diameter, the operating pressure, and the specific application requirements. Manufacturers often provide guidelines and specifications to help users make informed choices based on their unique needs.

In conclusion, wrapped surface hydraulic hoses stand out for their durability, pressure resistance, and versatility in various applications. Their design ensures that they can handle the rigor of industrial environments while providing reliable performance. Investing in high-quality wrapped surface hydraulic hoses can lead to improved productivity and reduced downtime, making them an essential consideration for any operation reliant on hydraulic power.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025