335345435

Nov . 28, 2024 05:23 Back to list

High-Pressure Hydraulic Hose Manufacturing with Wire Spiral Technology

The Importance of Wire Spiral High Pressure Hydraulic Hoses in Industrial Operations

In the world of industrial operations and machinery, hydraulic systems play a vital role in ensuring efficient movement and transfer of power. Among the various components that facilitate hydraulic functions, wire spiral high pressure hydraulic hoses stand out due to their robustness and reliability. These hoses are specifically designed to endure the demanding conditions often found in industrial settings, making them essential for many applications.

Understanding Wire Spiral High Pressure Hydraulic Hoses

Wire spiral hydraulic hoses are constructed using multiple layers of high-tensile steel wire, which are spiraled around an inner flexible tube. This design enables the hose to withstand high pressure while providing flexibility and durability. The adaptability of these hoses makes them suitable for a wide range of hydraulic fluids and systems operating under extreme pressure conditions. They are designed to resist abrasion, weather, and aging, which are crucial properties that contribute to their longevity and effectiveness.

Applications in Different Industries

Wire spiral high pressure hydraulic hoses are widely used across various industries, including construction, mining, agriculture, and manufacturing. In the construction sector, for instance, these hoses are critical in operating hydraulic machinery, such as excavators, bulldozers, and cranes. The robustness of these hoses ensures that they can handle the high pressure needed to perform heavy lifting tasks while maintaining consistent performance.

In the mining industry, where conditions can be harsh and unforgiving, these hoses are employed for hydraulic drills and other equipment that require high pressure for efficient operation

. The ability of wire spiral hoses to withstand extreme conditions, including shock and vibration, makes them indispensable in this field.Similarly, in agricultural applications, these hoses facilitate the operation of various equipment, including tractors and harvesters. As modern agriculture increasingly relies on hydraulic systems for effective operation, the reliability of wire spiral high pressure hoses cannot be overstated.

Factors to Consider When Choosing Hydraulic Hoses

wire spiral high pressure hydraulic hose factories

When selecting wire spiral high pressure hydraulic hoses, several factors must be taken into account. First and foremost, the pressure rating of the hose is crucial. It should match or exceed the maximum pressure of the hydraulic system it will be used in. Additionally, compatibility with the types of hydraulic fluids is essential to avoid deterioration of the hose material.

Another significant aspect is the temperature range in which the hoses will operate. Different applications may expose the hoses to varying temperature extremes, so choosing a hose that can withstand these conditions is imperative for optimal performance.

Length and diameter are also critical specifications. Properly fitting hoses ensure that the hydraulic system operates efficiently without leaks or the risk of bursting under pressure. Furthermore, the bend radius must be considered to avoid sharp turns that could damage the hose.

The Role of Factories in Producing Quality Hoses

The manufacturing of wire spiral high pressure hydraulic hoses requires precision and adherence to strict quality standards. Factories must ensure that every component, from the materials used to the final assembly, meets industry regulations to guarantee safety and reliability. The production process typically involves advanced technologies and rigorous testing procedures to ensure that the hoses can withstand the pressures and conditions they will face in real-world applications.

Moreover, reputable manufacturers often offer guarantees and warranties on their products, which signifies confidence in the quality and durability of their hoses. This assurance is vital for industries where equipment failure can lead to costly downtime and safety hazards.

Conclusion

Wire spiral high pressure hydraulic hoses are an integral component of many industrial applications. Their ability to handle high pressure while maintaining flexibility and durability makes them invaluable in sectors ranging from construction to agriculture. When choosing the right hose for a specific application, factors such as pressure ratings, compatibility, and environmental conditions must be considered. The role of factories in producing these hoses is crucial, as quality manufacturing ensures safety and performance in demanding environments. Ultimately, investing in high-quality wire spiral hydraulic hoses is essential for the efficiency and longevity of hydraulic systems across various industries.

-

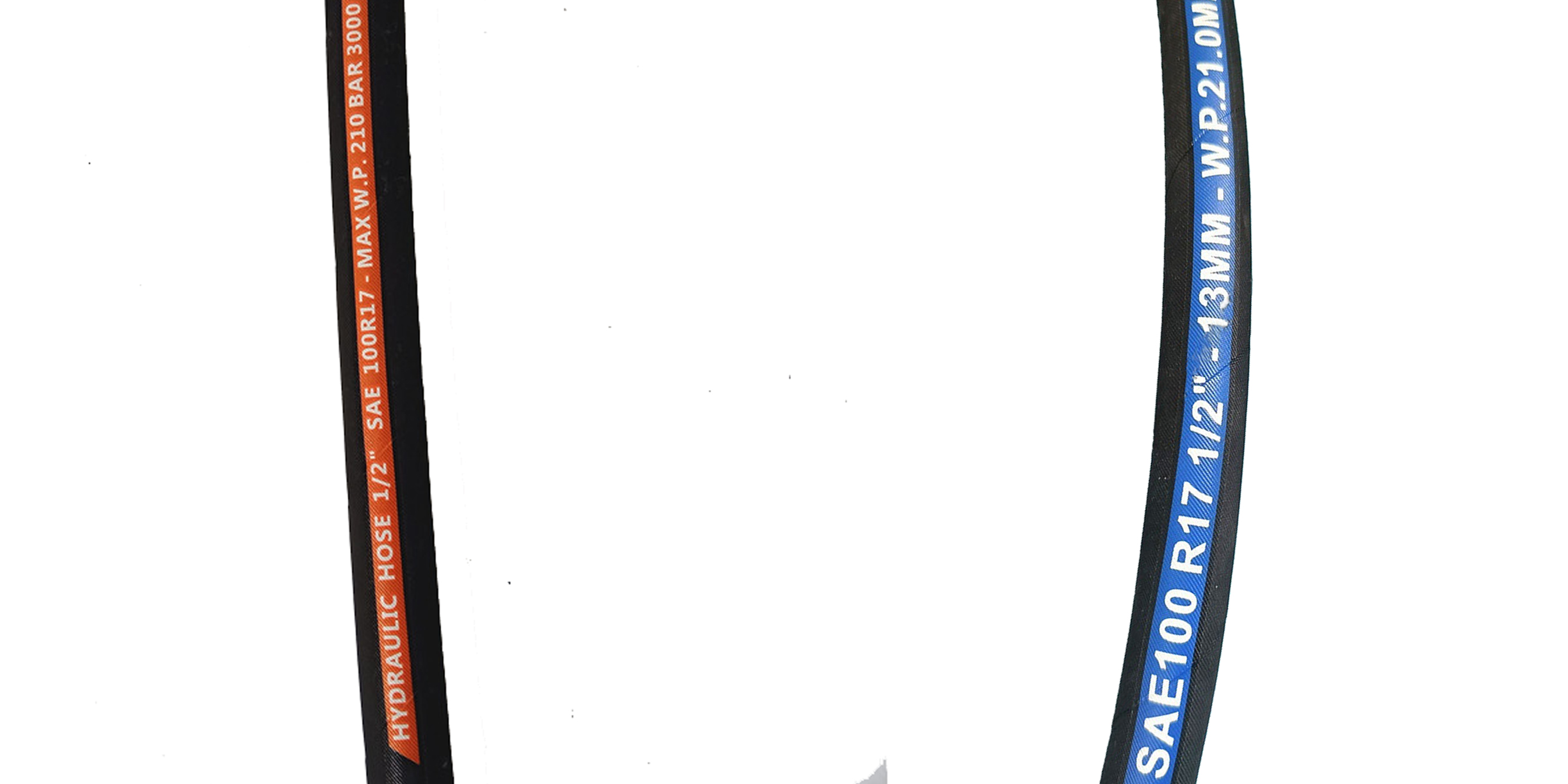

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025