335345435

Aug . 13, 2024 15:26 Back to list

Understanding Hydraulic Hoses and Fittings for Optimal Performance in Fluid Power Systems

Understanding Hydraulic Hoses and Fittings Essential Components of Fluid Power Systems

Hydraulic hoses and fittings are vital components in fluid power systems, commonly used in various industries such as construction, manufacturing, agriculture, and automotive. These elements play a crucial role in the transfer of fluids, enabling machinery and equipment to achieve the desired force and motion.

Hydraulic Hoses A Closer Look

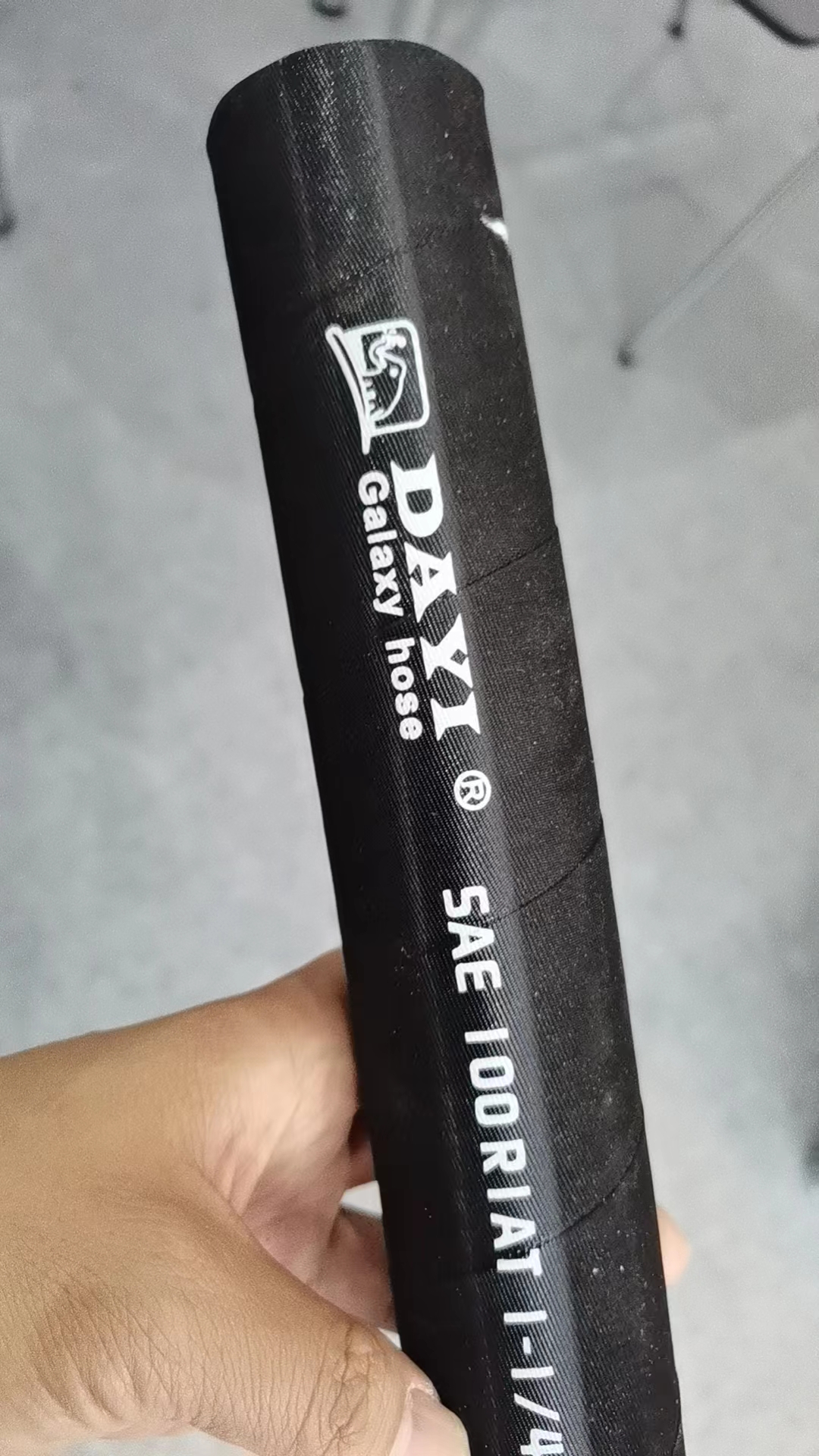

Hydraulic hoses are flexible tubes designed to transport hydraulic fluids in a safe and efficient manner. They are engineered to withstand high pressure and extreme temperatures, making them suitable for demanding applications. Hoses are typically constructed from an inner tube, reinforcement layers, and an outer cover. The inner tube is made from materials such as rubber or thermoplastic, designed to resist the corrosive effects of hydraulic fluids.

The reinforcement layers, usually made from steel wire or textile, provide structural integrity and prevent the hose from collapsing under pressure. The outer cover acts as a protective layer against environmental factors such as abrasion, UV light, and chemicals. Given these characteristics, hydraulic hoses come in different types, including low, medium, and high-pressure hoses, catering to various operational needs.

The Importance of Selecting the Right Hose

Choosing the right hydraulic hose is crucial for the longevity and efficiency of a hydraulic system. Several parameters must be considered during this selection process, including the type of fluid being transported, the operating temperature, and the working pressure. Additionally, the hose's bend radius and flexibility should match the specific application to avoid kinks and potential damage.

Regular maintenance and inspection of hydraulic hoses are also important to prevent leaks and ensure optimal performance. Hoses can degrade over time due to wear and tear, necessitating timely replacement to maintain the integrity of the hydraulic system.

hydraulic hose and fitting

Hydraulic Fittings Connecting Components

Hydraulic fittings serve as the connection points between hoses and hydraulic components, including pumps, cylinders, and valves. These fittings are critical in ensuring a leak-free, secure connection for efficient fluid transfer. Just like hoses, hydraulic fittings come in various materials, including steel, brass, and plastic, and they are designed to withstand the same pressures and temperatures as the hoses.

There are various types of hydraulic fittings, including threaded, crimped, and push-on fittings. Threaded fittings use threaded connections to secure hoses and components, while crimped fittings are mechanically pressed onto the hose for a tight fit. Push-on fittings provide a quicker and easier assembly without the need for specialized tools. The choice of fitting type depends on the specific application and operational requirements.

Ensuring Safety and Reliability

Safety is paramount in the design and use of hydraulic hoses and fittings. A failure in any component can lead to catastrophic results, including equipment damage and workplace accidents. Consequently, industries utilize safety standards and regulations to ensure that hydraulic systems are designed and maintained properly. Regular inspections, adherence to guidelines, and proper training for personnel handling hydraulic systems are essential practices for minimizing risks.

Conclusion

Hydraulic hoses and fittings are integral to a wide range of applications, enabling the efficient transfer of hydraulic fluids necessary for powering machinery. Understanding their construction, selection, and maintenance is crucial for ensuring the reliability and safety of hydraulic systems. As industries continue to evolve, advancements in hose and fitting technology will further enhance the efficiency and performance of fluid power systems, paving the way for innovative solutions and improved operational practices.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025