335345435

Aug . 01, 2024 05:31 Back to list

Understanding Hydraulic Flexible Hose Fittings for Efficient Fluid Transfer in Various Applications

The Importance of Hydraulic Flexible Hose Fittings in Modern Industries

In today's world, hydraulic systems are integral to various industries, from construction and manufacturing to automotive and aerospace. At the heart of these systems are hydraulic flexible hose fittings, which play a crucial role in ensuring effective and efficient fluid transfer. Understanding the importance of these fittings is essential for anyone involved in the design, maintenance, or operation of hydraulic systems.

What Are Hydraulic Flexible Hose Fittings?

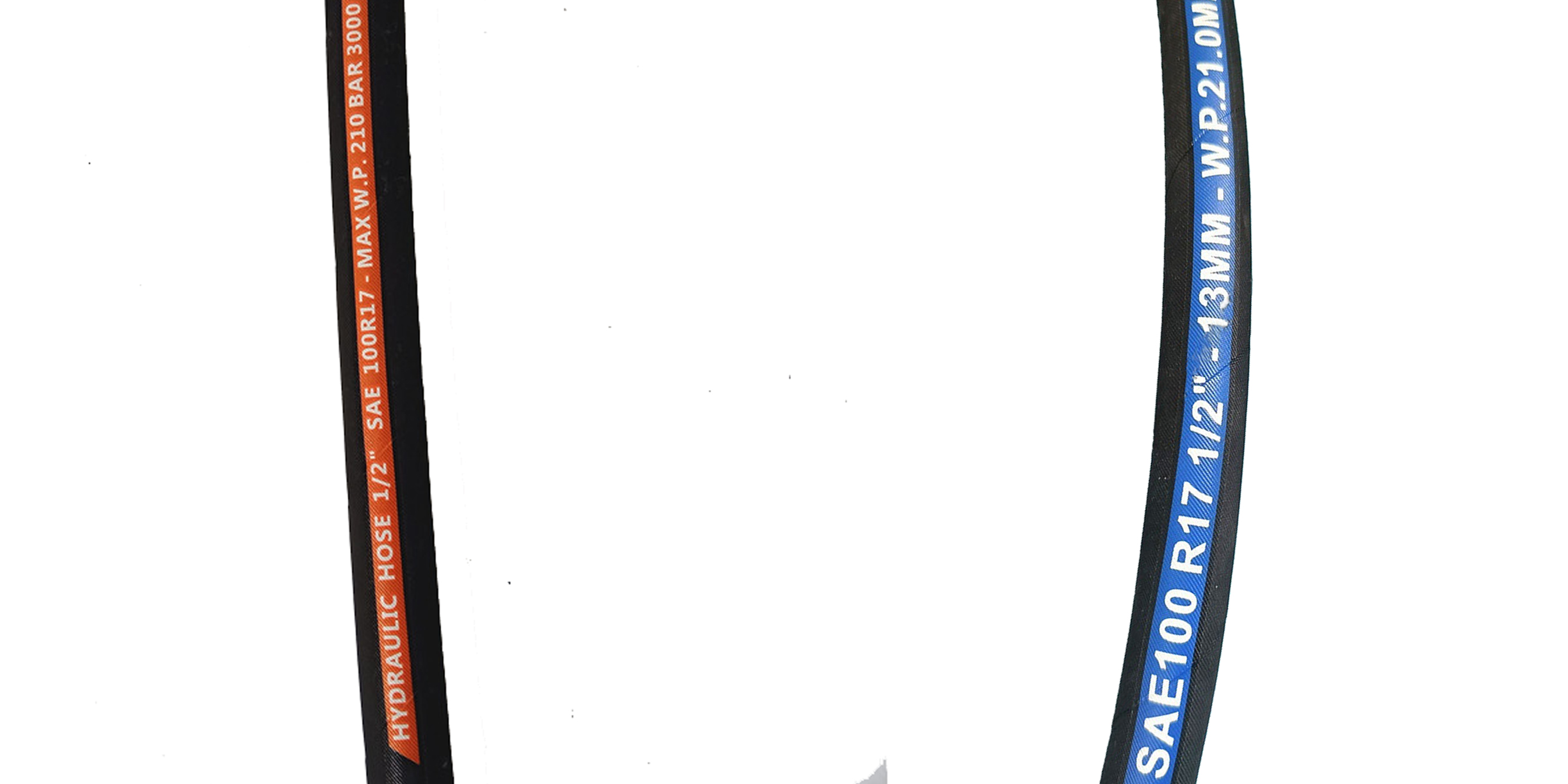

Hydraulic flexible hose fittings are specialized components that connect hydraulic hoses to various machinery and equipment. These fittings ensure a secure, leak-free connection, allowing hydraulic fluid to flow between different parts of a hydraulic system. They come in various shapes, sizes, and materials, designed to accommodate different pressure levels and fluid types. Common materials used for these fittings include stainless steel, brass, and other alloys that offer both strength and resistance to corrosion.

Key Features and Benefits

1. Flexibility and Maneuverability One of the most significant advantages of hydraulic flexible hose fittings is their ability to allow for flexibility in hydraulic systems. This flexibility is crucial in applications where machinery may move or where space constraints prevent the use of rigid piping. The ability to navigate around obstacles and still maintain a secure connection enhances the overall efficiency of the system.

2. Ease of Installation Flexible hose fittings are typically easier to install than rigid fittings. Their design allows for quick connections and disconnections, which can save time during both initial installation and subsequent maintenance. This ease of handling is invaluable in operational settings where downtime needs to be minimized.

hydraulic flexible hose fittings

3. Resistance to Vibration and Movement In industrial environments, machinery is often subject to vibrations and movements. Hydraulic flexible hose fittings are designed to withstand these conditions without jeopardizing the integrity of the connection. This characteristic helps prevent leaks and ensures that hydraulic systems function reliably under various conditions.

4. Diverse Applications Hydraulic flexible hose fittings are employed in numerous applications. From connecting hydraulic hoses in construction equipment like excavators and cranes to ensuring safe fluid transfer in manufacturing machinery, their versatility makes them indispensable across multiple sectors. Additionally, they are essential in automotive systems for power steering and brake functions, demonstrating their broad applicability.

Maintenance and Safety Considerations

While hydraulic flexible hose fittings are designed for durability, regular maintenance is essential to ensure their longevity and performance. Inspections should focus on checking for signs of wear, corrosion, and leakage. Proper tightening of fittings can prevent loosening and potential failures. Furthermore, using fittings that are compatible with the hydraulic fluid and pressure specifications is critical for maintaining safety standards.

Safety must always be a priority in any hydraulic system. Using high-quality hose fittings, following proper installation procedures, and adhering to manufacturer guidelines can mitigate risks associated with system failures. Training personnel on safe handling and maintenance practices is also crucial to prevent accidents and enhance operational efficiency.

Conclusion

Hydraulic flexible hose fittings are a vital component of modern hydraulic systems, providing the flexibility, reliability, and ease of installation that industries demand. Their ability to withstand the rigors of various applications while ensuring secure fluid transfer makes them indispensable in manufacturing, construction, automotive, and many other fields. As technology continues to evolve, so too will the designs and functionalities of these fittings, further enhancing the effectiveness of hydraulic systems around the world. Proper understanding and maintenance of these fittings will go a long way in ensuring safety, efficiency, and performance in hydraulic operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025