335345435

Nov . 20, 2024 20:21 Back to list

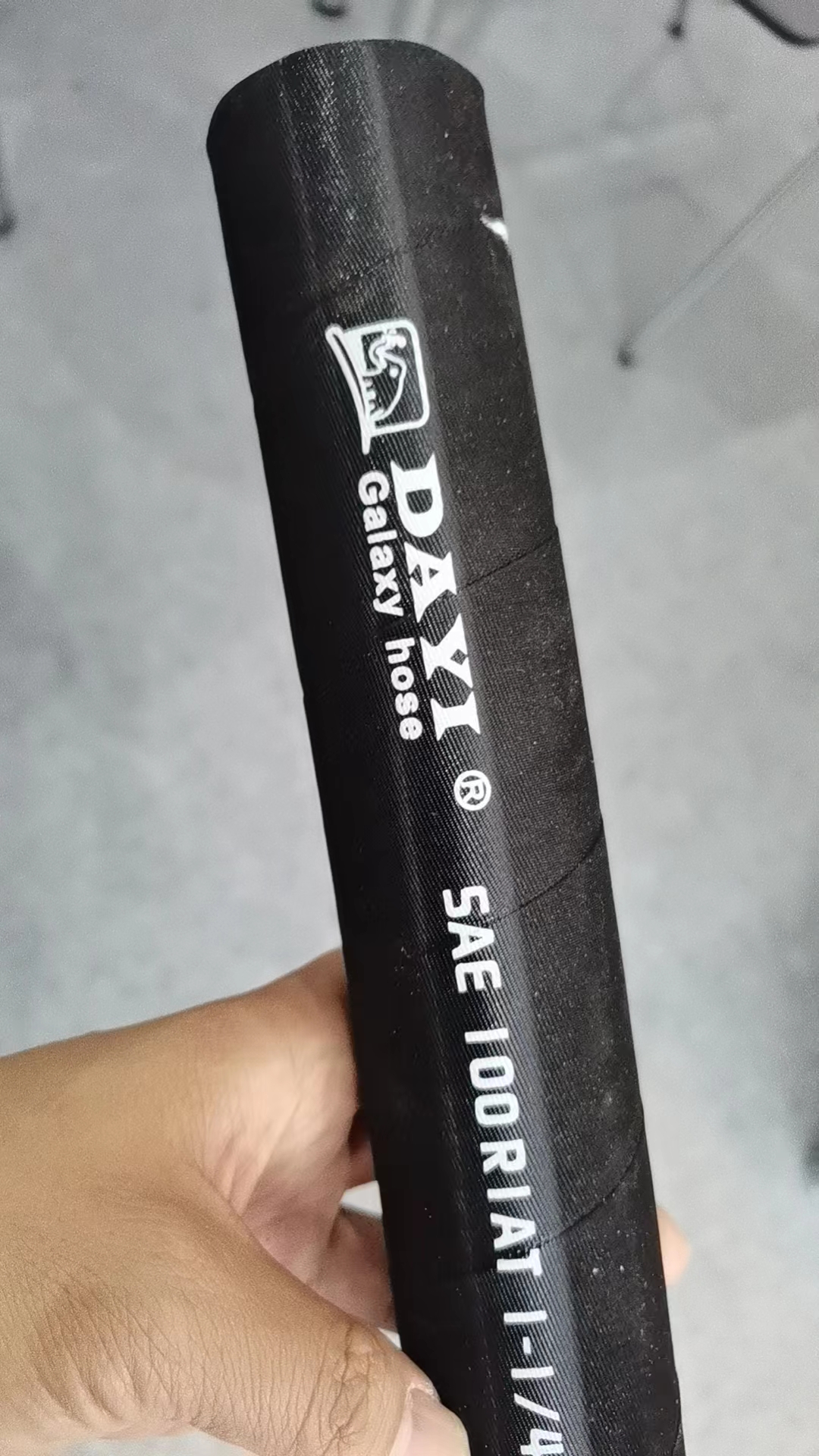

two wire braided hydraulic hose manufacturer

Understanding Two Wire Braided Hydraulic Hoses and Their Manufacturers

Hydraulic systems are crucial in various industries, from construction and manufacturing to agriculture and automotive. Among the essential components in these systems are hydraulic hoses, which are responsible for transporting fluid under high pressure. One of the most popular types of hydraulic hoses is the two wire braided hydraulic hose. This article delves into the characteristics of these hoses and the role of manufacturers in ensuring quality and reliability.

What is a Two Wire Braided Hydraulic Hose?

A two wire braided hydraulic hose is designed to withstand high pressure and is made up of a rubber or thermoplastic core that is reinforced with two layers of steel wire braiding. This construction helps enhance the hose's strength, flexibility, and durability, making it well-suited for various hydraulic applications. The key features of these hoses include

1. Pressure Rating Two wire braided hoses typically have a high maximum working pressure, which often ranges between 1500 to 6000 PSI, depending on the specific application and the materials used in construction.

2. Temperature Resistance They can endure a wide temperature range, usually from -40°F to 212°F (-40°C to 100°C), making them suitable for both cold and hot environments.

3. Flexibility Despite their robust build, these hoses offer a good degree of flexibility, allowing for easy installation in tight spaces.

4. Abrasion Resistance The outer layer of the hose often includes an abrasion-resistant cover, which protects it from wear and tear caused by external factors.

The Role of Manufacturers

Manufacturers of two wire braided hydraulic hoses play a pivotal role in ensuring that these products meet the highest standards of quality and safety

. Here are several critical aspects of their role1. Material Selection Quality manufacturers carefully select materials that enhance the performance and longevity of the hydraulic hoses. The choice of rubber compounds, steel wire grades, and outer covers is crucial in determining the hose's overall resistance to wear, temperature, and pressure.

2. Manufacturing Techniques Advanced manufacturing techniques, including precise braiding methods and uniform curing processes, are essential for creating reliable hydraulic hoses. Leading manufacturers invest in state-of-the-art machinery to ensure consistency and high-quality production.

two wire braided hydraulic hose manufacturer

3. Testing and Certification Reputable manufacturers conduct rigorous testing on their hoses to verify their performance. This includes pressure tests, flexibility tests, and exposure to varying temperatures and environmental conditions. Many manufacturers also adhere to international standards, such as ISO and SAE, which provide guidelines for safety and performance.

4. Customization Depending on client needs, manufacturers often offer customization options for hydraulic hoses. This may include varying lengths, diameters, and specialized fittings that enhance compatibility with different hydraulic systems.

5. Technical Support and Expertise A knowledgeable manufacturer provides technical support and guidance to customers who may require assistance in selecting the right hose for their application. Their expertise helps ensure that customers make informed decisions based on their specific needs.

Choosing the Right Manufacturer

When selecting a manufacturer of two wire braided hydraulic hoses, several factors should be considered

- Reputation Look for manufacturers with a good reputation in the industry, backed by positive reviews and testimonials from previous clients.

- Experience Companies with years of experience are often more reliable, as they have a proven track record of producing quality products.

- Certifications Ensure that the manufacturer complies with relevant industry standards and certifications, which can be indicative of their commitment to quality.

- Warranty and Support A solid warranty and excellent customer support are essential. These factors can protect your investment and provide peace of mind.

Conclusion

Two wire braided hydraulic hoses are invaluable components in hydraulic systems, offering strength, flexibility, and durability. Manufacturers play a crucial role in ensuring that these hoses meet the necessary quality standards, allowing various industries to rely on their performance. By choosing the right manufacturer, businesses can enhance their hydraulic systems’ efficiency and safety, ultimately contributing to smoother operations and better outcomes. Whether for construction machinery, agricultural equipment, or automotive applications, quality hydraulic hoses are imperative for success.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025