335345435

Dec . 11, 2024 04:46 Back to list

Two Wire Braided Hydraulic Hose Production and Supply by Top Manufacturer

Understanding Two Wire Braided Hydraulic Hose Manufacturing

Hydraulic hoses are a critical component in various industrial applications, and the two wire braided hydraulic hose is among the most durable and reliable options available in the market. As industries advance, the demand for high-quality hydraulic hoses has led to the growth of specialized manufacturers focused on producing these essential components. In this article, we will explore the manufacturing process, benefits, and applications of two wire braided hydraulic hoses.

What is a Two Wire Braided Hydraulic Hose?

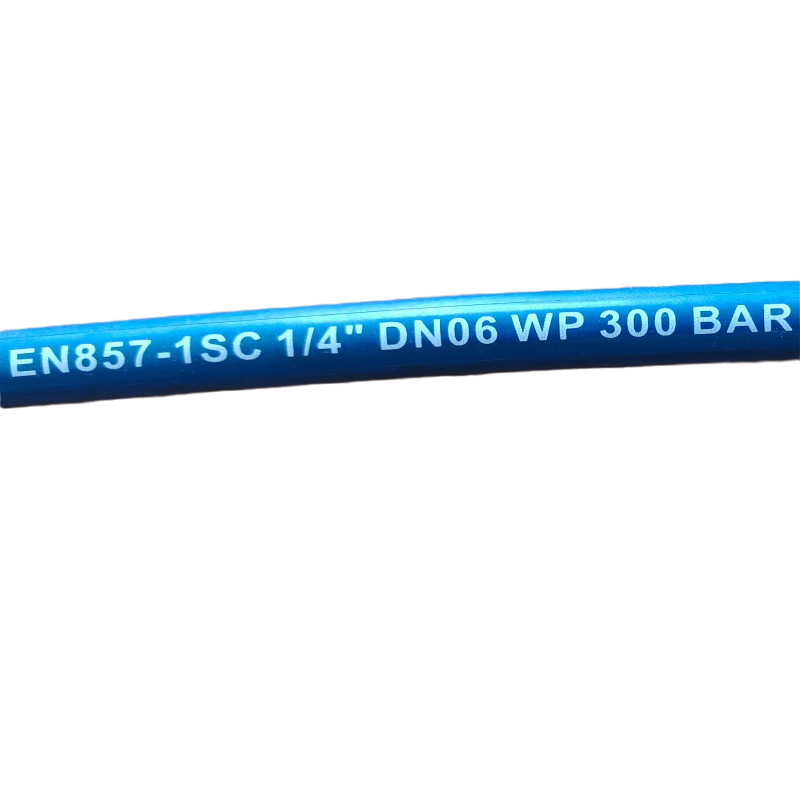

A two wire braided hydraulic hose consists of a rubber or synthetic rubber tube that is reinforced with two layers of braided wire. These wires are typically made of high tensile steel, which greatly enhances the hose's strength and flexibility. The outer layer may be protected with additional materials to resist abrasion and environmental factors.

Manufacturing Process

The manufacturing of two wire braided hydraulic hoses involves several intricate steps

1. Raw Material Selection The foundation of high-quality hoses lies in the selection of raw materials. The type of rubber used must withstand high pressure and various environmental conditions. Additionally, the steel wire must have the necessary tensile strength to provide the required reinforcement.

2. Tube Formation The rubber or synthetic rubber material is formed into a tube using advanced extrusion methods. This tube will serve as the inner lining of the hose, carrying the hydraulic fluid.

3. Wire Braiding Once the tube is formed, the two wire braiding process begins. Machines weave wire around the tube in a specific pattern, typically at a 45-degree angle, creating a strong, cohesive structure. This braiding process is crucial as it allows the hose to withstand high pressures without bursting.

4. Cover Application After the braiding process, a protective cover is added to the hose. This cover, made of abrasion-resistant materials, protects the inner tube and braiding from external damages caused by environmental factors or wear and tear.

5. Curing The final stage involves curing the hose in an oven, where heat is applied to bond the materials together. This vulcanization process enhances the durability and elasticity of the hose, making it suitable for the most demanding applications.

Advantages of Two Wire Braided Hydraulic Hoses

two wire braided hydraulic hose manufacturer

1. High Pressure Resistance One of the primary advantages of these hoses is their ability to handle high pressures, often exceeding 4000 psi. This makes them ideal for applications in heavy machinery and equipment.

2. Flexibility Despite their strength, two wire braided hydraulic hoses are flexible, allowing for easier installation and maneuvering in tight spaces.

3. Durability The combination of rubber and steel braiding provides excellent resistance to abrasion, oil, and various chemicals. This durability ensures longevity, reducing replacement frequency and maintenance costs.

4. Versatility These hoses can be used in a wide range of applications, including construction, agriculture, and manufacturing, accommodating various hydraulic fluids and environmental conditions.

Applications

Two wire braided hydraulic hoses are widely used in different sectors due to their robust nature

- Construction Machinery They are commonly found in excavators, bulldozers, and cranes, where high-pressure hydraulic systems are essential for operation.

- Agricultural Equipment Tractors and harvesters utilize these hoses to efficiently manage hydraulic fluids needed for their various functions.

- Manufacturing and Industrial Equipment From conveyor systems to presses, many industrial machines rely on the strength of two wire braided hoses to function effectively.

Conclusion

Choosing the right hydraulic hose is vital for ensuring operational efficiency and longevity in various industrial applications. Manufacturers specializing in two wire braided hydraulic hoses play a crucial role in providing durable and flexible solutions that meet the high demands of the industry. As technology advances and manufacturing techniques improve, we can expect even greater innovations in the production of these essential components, further contributing to the safety and efficiency of hydraulic systems worldwide.

-

Premium Distribution PTFE Hose: Flexible & Durable Solutions

NewsAug.22,2025

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025

-

Premium 38mm Hydraulic Hose Factories | Direct & Reliable

NewsAug.08,2025