335345435

Dec . 04, 2024 02:21 Back to list

Suppliers of Two-Ply Fiber Braid Hydraulic Hoses for Reliable Performance and Durability

Two Fiber Braid Hydraulic Hose Suppliers A Comprehensive Overview

Hydraulic hoses are indispensable components in various industries, facilitating the efficient transmission of fluids under high pressure. Among the many types of hydraulic hoses available in the market, the two fiber braid hydraulic hose stands out due to its excellent structural integrity and flexibility. This article delves into the characteristics, applications, and selection of suppliers for two fiber braid hydraulic hoses.

Understanding Two Fiber Braid Hydraulic Hoses

Two fiber braid hydraulic hoses consist of a rubber inner tube that carries the fluid, reinforced with two layers of braided fiber. This unique construction enhances the hose's pressure tolerance and makes it resistant to wear and abrasion. The fibers typically used in these hoses include synthetic materials such as polyester or nylon, which contribute to their overall strength and durability.

The primary advantage of two fiber braid hydraulic hoses is their flexibility. This feature allows them to be easily routed through tight spaces and makes them ideal for applications where movement and bending are frequent. Additionally, these hoses can withstand a wide range of temperatures and pressures, making them suitable for various hydraulic systems.

Applications of Two Fiber Braid Hydraulic Hoses

The versatility of two fiber braid hydraulic hoses allows them to be employed in multiple industries, including

1. Construction Used in machinery such as excavators, bulldozers, and cranes, these hoses are vital for transferring hydraulic fluids that power the equipment's movements.

2. Agriculture Modern agricultural machinery relies on hydraulic systems for various functions, including lifting, steering, and controlling implements. Two fiber braid hoses are essential in ensuring the smooth operation of these machines.

3. Manufacturing In industrial environments, hydraulic hoses are critical for powering machines, conveyors, and robotic systems. The durability of two fiber braid hoses ensures minimal downtime and maintenance.

4. Automotive Used in hydraulic braking systems and power steering, these hoses are crucial for the safe and efficient operation of vehicles.

two fiber braid hydraulic hose suppliers

5. Marine Two fiber braid hydraulic hoses are also utilized in marine applications, where their resistance to harsh environments and flexibility make them suitable for boats and ships.

Selecting the Right Supplier

Choosing the right supplier for two fiber braid hydraulic hoses is essential for ensuring high-quality products that meet your application requirements. Here are some factors to consider when selecting a supplier

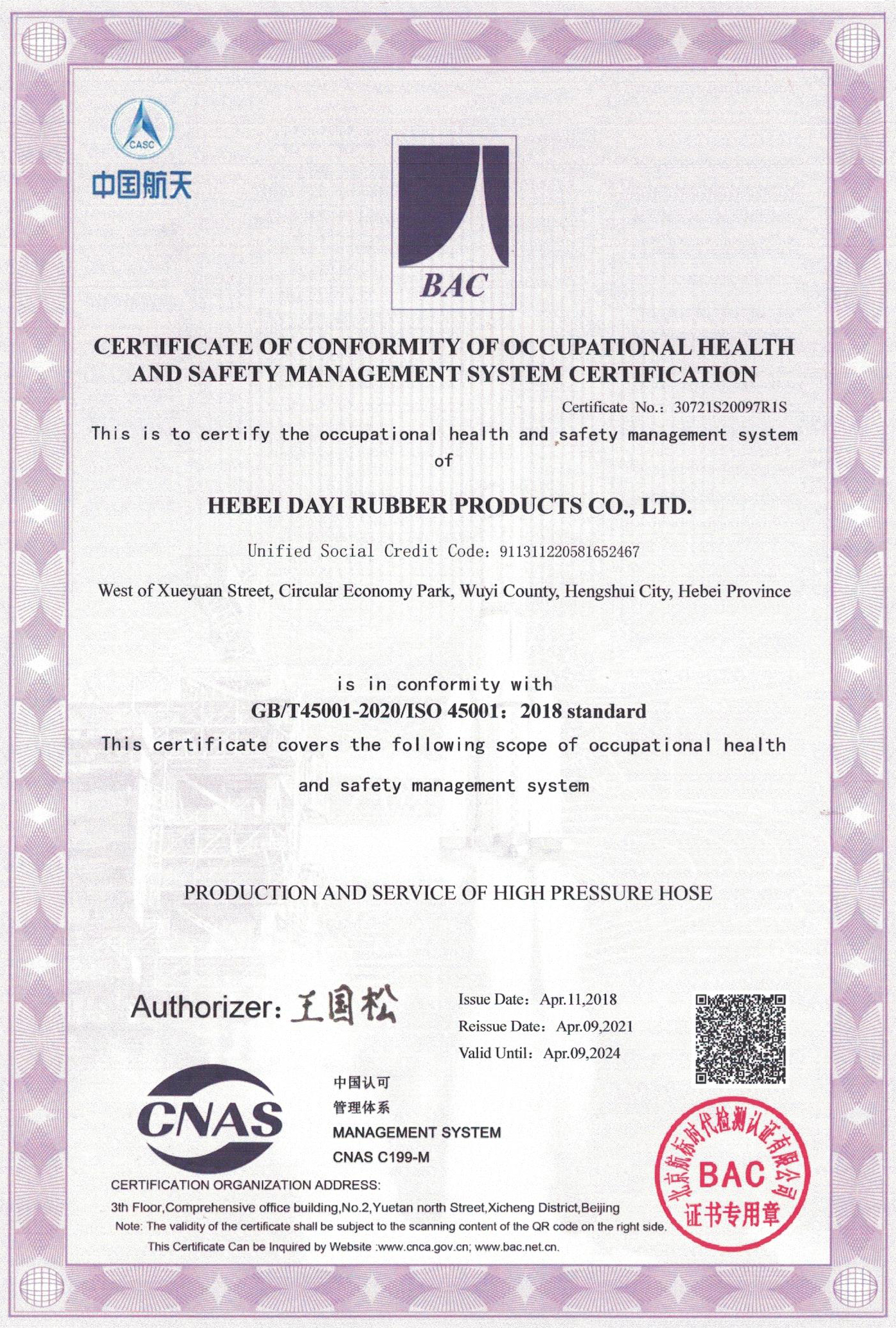

1. Quality Standards Ensure that the supplier adheres to industry standards and quality certifications. This not only guarantees the performance of the hoses but also ensures safety in your hydraulic systems.

2. Product Range A reliable supplier should offer a diverse range of hydraulic hoses, including various sizes, pressure ratings, and materials. This flexibility allows customers to find the exact hose that fits their specific needs.

3. Customization Look for suppliers that offer customization options, such as length, diameter, and additional features, to create a hose tailored to your application requirements.

4. Technical Support A great supplier will provide excellent customer service, including technical support and advice on the best products for your specific applications.

5. Pricing and Availability Competitive pricing and the ability to deliver products promptly are essential qualities in a supplier. Ensure that they can meet your delivery schedules without compromising on quality.

Conclusion

Two fiber braid hydraulic hoses are integral to many industrial applications, providing durability, flexibility, and reliability. By carefully selecting a supplier who meets your quality, customization, and service needs, you can ensure the optimal performance of your hydraulic systems. With a vast range of applications, these hoses are bound to enhance efficiency and productivity in various sectors. Therefore, investing time in finding the right supplier is as crucial as the hydraulic hoses themselves.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025