335345435

Aug . 15, 2024 13:46 Back to list

Top OEM Manufacturers of Automatic Crimping Machines for Precision Engineering Applications

The Role of OEM Automatic Crimping Machine Manufacturers in Modern Industries

In the fast-evolving landscape of manufacturing, the demand for precision, efficiency, and customizability has turned traditional production methods on their heads. Among the various machines that have revolutionized assembly lines, automatic crimping machines stand out as essential tools, particularly in industries like electronics, automotive, and telecommunications. Entering the arena of OEM (Original Equipment Manufacturer) automatic crimping machine manufacturers, these companies play a pivotal role in enhancing production capabilities tailored to specific industry needs.

Understanding Automatic Crimping Machines

Automatic crimping machines are designed to permanently join two pieces of metal or other materials by compressing them together, a process known as crimping. The precision and speed of these machines greatly increase production efficiency while ensuring high-quality connections essential for the functionality of the end product. Whether it’s for electrical connectors, automotive wiring harnesses, or specialized industrial cabling, these machines offer a level of consistency that manual methods simply cannot achieve.

The Importance of OEM Manufacturers

OEM manufacturers focus on producing components or systems for other companies, often tailored to meet specific requirements. In the context of automatic crimping machines, OEM manufacturers deliver bespoke solutions that cater to the unique specifications of clients across diverse sectors. This customizability is vital because different applications can require different types of crimping.

For example, the automotive industry might need machines capable of handling high-voltage cables with precise connections for electric vehicles, while the consumer electronics sector may require compact machines for smaller connectors. OEM manufacturers, through their sophisticated design and engineering capabilities, are able to create machines that can fit these varied needs, often integrating advanced technology like artificial intelligence and machine learning to optimize performance.

oem automatic crimping machine manufacturer

Benefits of Choosing OEM Manufacturers

1. Customization One of the primary advantages of partnering with OEM manufacturers is the level of customization they provide. They work closely with clients to understand their processes and product requirements, ensuring that the machines they produce are not only fit for purpose but also enhance the overall productivity of the operation.

2. Quality Assurance OEMs tend to have stringent quality control processes in place. This ensures that the machines they produce meet industry standards and perform reliably under the demanding conditions of high-speed manufacturing environments.

3. Technical Support and Maintenance Many OEM manufacturers offer comprehensive support services, from installation to ongoing maintenance. This continued support helps clients extend the life of their machines and optimize their operational efficiency.

4. Innovation The landscape of industrial machinery is dynamic, characterized by rapid technological advancement. OEM manufacturers are at the forefront of this innovation, frequently updating their machines to incorporate the latest technologies, such as better user interfaces, automated features, and enhanced energy efficiency.

Conclusion

As industries continue to evolve and demands for specialized solutions grow, OEM automatic crimping machine manufacturers are crucial players in the manufacturing ecosystem. Their ability to deliver customized, high-quality, and technologically advanced machines positions them as invaluable partners for companies striving for operational excellence. The integration of these advanced crimping solutions not only enhances production efficiency but also contributes to the overall quality and reliability of the final products in a myriad of applications. In a competitive market, the support and innovation provided by OEM manufacturers could very well be the key to unlocking new levels of success.

-

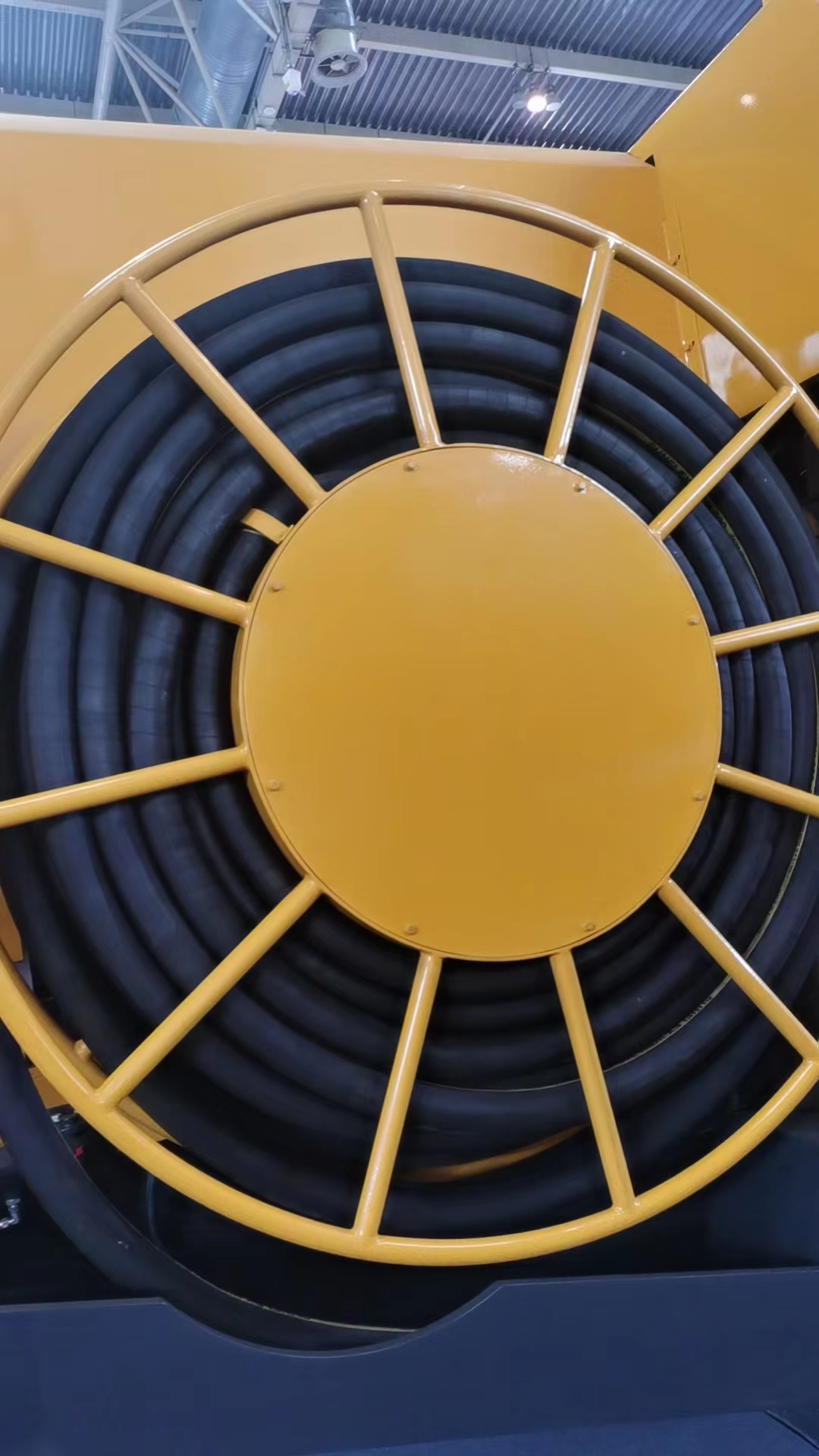

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025