335345435

Nov . 07, 2024 19:38 Back to list

Leading Manufacturers of Durable Thermoplastic Hoses for Various Applications

The Rise of Thermoplastic Hose Manufacturers A Look into the Industry

In today's industrial landscape, thermoplastic hoses are pivotal in various applications, including automotive, aerospace, construction, and fluid transfer. These hoses are renowned for their lightweight, flexibility, and resistance to chemicals, making them a preferred choice for numerous industries. As the demand for efficient and sustainable solutions increases, the role of thermoplastic hose manufacturers has never been more critical.

Understanding Thermoplastic Hoses

Thermoplastic hoses are made from polymers that become pliable or moldable above a specific temperature and solidify upon cooling. This unique property allows manufacturers to produce hoses that are not only robust and durable but also capable of enduring high pressures and varying temperatures.

The primary materials used in the production of thermoplastic hoses include nylon, polyethylene, and polyurethane, among others. These materials provide excellent resistance to abrasions, impacts, and harsh chemical environments, making thermoplastic hoses ideal for applications where traditional rubber hoses may fail.

The Manufacturing Process

The process of manufacturing thermoplastic hoses involves several stages, including extrusion, braiding, and testing. Initially, raw thermoplastic materials are heated and extruded into the desired hose shape. This is followed by the incorporation of reinforcing fibers, often through a braiding process, which enhances the hose's strength and flexibility.

Once the hoses are formed, they undergo rigorous testing to ensure they meet industry standards for pressure and temperature resistance. This quality control is crucial, as any failure during operation can lead to significant safety hazards and increased costs.

Market Dynamics

The global market for thermoplastic hoses is experiencing significant growth, driven by advancements in technology and the rising need for high-performance materials in various industries. With the increasing focus on efficiency and sustainability, manufacturers are continuously innovating to produce hoses that are not only high-performing but also environmentally friendly.

thermoplastic hose manufacturers manufacturer

Several key manufacturers dominate this market, offering a wide range of products tailored to meet specific industry needs. These manufacturers are investing heavily in research and development to enhance the performance characteristics of their hoses, including improved flexibility, kink resistance, and chemical compatibility. Additionally, many are adopting eco-friendly materials and production methods in response to growing environmental concerns.

Applications of Thermoplastic Hoses

Thermoplastic hoses find applications in a myriad of sectors. In the automotive industry, they are used for fuel lines, coolant systems, and brake lines due to their ability to withstand high pressures and temperatures. The aerospace sector relies on these hoses for hydraulic systems and fuel transfer, where reliability and performance are paramount.

In construction and agriculture, thermoplastic hoses are employed for water transfer, irrigation systems, and pneumatic tools. Their lightweight design reduces strain on workers and enhances mobility on job sites.

Moreover, the chemical industry benefits from thermoplastic hoses’ resistance to aggressive chemicals, making them ideal for transporting various fluids safely.

Future Trends

Looking ahead, the thermoplastic hose manufacturing industry is poised for further innovation. Trends such as the integration of smart technology into hoses, enabling real-time monitoring of performance and conditions, are on the horizon. Additionally, biocompatible thermoplastic hoses are gaining traction in the medical industry for applications such as fluid transfer and patient monitoring.

Sustainability remains a priority, with manufacturers exploring biodegradable materials and recycling processes to minimize environmental impact. As regulations regarding environmental safety become stricter, companies that prioritize eco-friendly practices will likely gain a competitive edge.

Conclusion

Thermoplastic hose manufacturers play a vital role in providing solutions that meet the evolving demands of various industries. As technology advances and market needs change, these manufacturers are adapting by focusing on performance, sustainability, and innovation. The future of thermoplastic hoses looks bright, underscored by the industry's commitment to quality, safety, and environmental responsibility. As companies continue to invest in research and development, the potential for growth and technological advancement in this sector remains limitless.

-

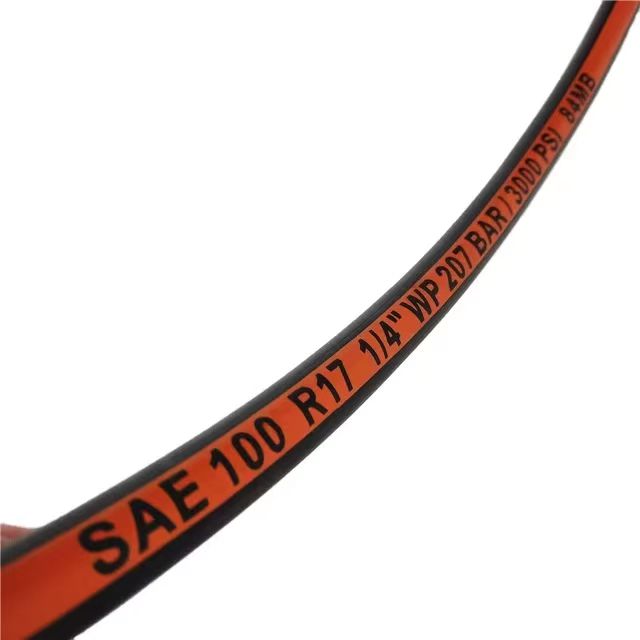

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025