335345435

Oct . 04, 2024 08:46 Back to list

thermoplastic hose manufacturers factory

The Role of Thermoplastic Hose Manufacturers in Today's Industry

In the modern industrial landscape, thermoplastic hoses have emerged as essential components across various sectors, including automotive, aerospace, construction, and agriculture. The versatility, durability, and lightweight nature of thermoplastic hoses make them a popular choice among manufacturers and consumers alike. This article explores the significance of thermoplastic hose manufacturers and the benefits they bring to various industries.

Understanding Thermoplastic Hoses

Thermoplastic hoses are made from polymer materials that become pliable or moldable when heated and solidify upon cooling. This unique property allows them to be easily manufactured into various shapes and sizes. Unlike rubber hoses, thermoplastic options offer superior resistance to abrasion, chemicals, and extreme temperatures, which enhances their performance and lifespan.

The Manufacturing Process

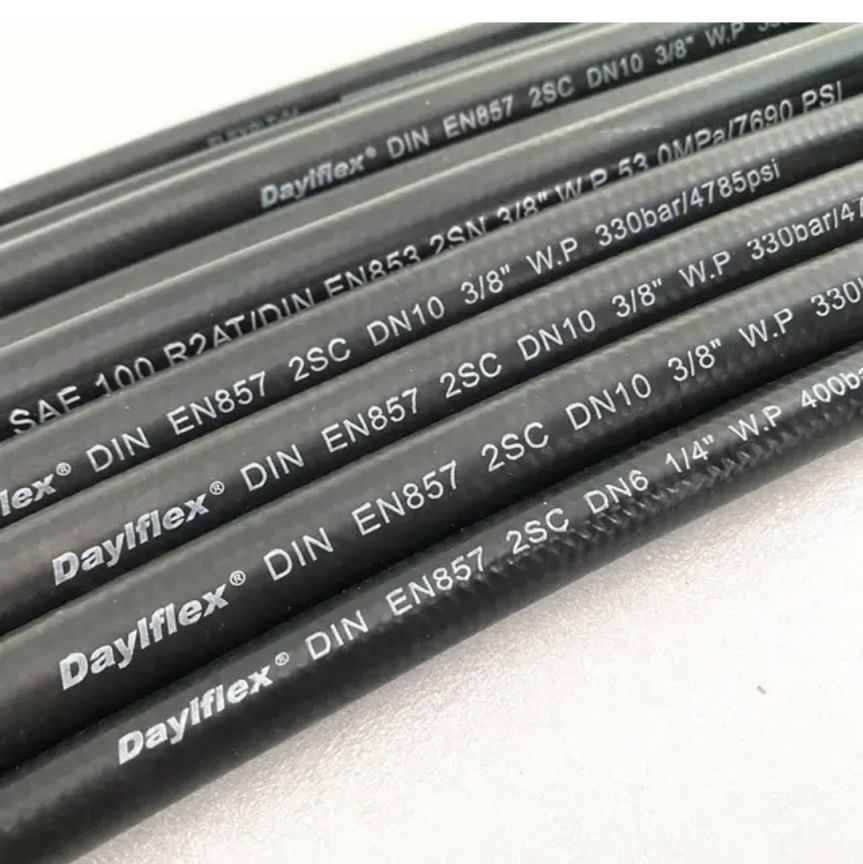

The process of producing thermoplastic hoses involves several key stages, including material selection, extrusion, braiding, and quality testing. Manufacturers often work with a variety of thermoplastic materials, such as polyurethane, nylon, and PVC, each chosen for specific applications based on their properties.

The extrusion process shapes the heated polymer into the desired diameter and length. Following extrusion, many hoses undergo a braiding process using high-strength fibers to enhance their strength and flexibility. This is particularly crucial for high-pressure applications. Finally, quality testing is conducted to ensure that the hoses meet industry standards and specifications.

Importance of Thermoplastic Hose Manufacturers

thermoplastic hose manufacturers factory

1. Innovation and Customization Thermoplastic hose manufacturers are at the forefront of innovation in material science and engineering. They continuously develop new formulations that enhance the performance characteristics of hoses. Additionally, they offer customization options to meet the specific needs of industries, providing hoses with varying pressures, diameters, and chemical resistance.

2. Sustainability As industries worldwide aim for more sustainable practices, thermoplastic hoses provide a viable alternative to traditional rubber hoses. Many manufacturers are adopting eco-friendly practices, utilizing recyclable materials and reducing waste during the production process. This shift not only benefits the environment but also appeals to eco-conscious consumers.

3. Cost-Effectiveness The lightweight nature of thermoplastic hoses leads to reduced shipping costs and easier handling, translating to cost savings for companies. Furthermore, their durability minimizes the frequency of replacements, making them a cost-effective solution for many applications.

4. Diverse Applications Thermoplastic hoses are incredibly versatile and can be utilized in a variety of applications. From hydraulic systems in heavy machinery to fluid transfer in the food and beverage industry, the adaptability of these hoses opens up numerous possibilities for manufacturers.

5. Safety and Compliance Manufacturers prioritize safety and compliance with industry regulations. High-quality thermoplastic hoses are designed to meet rigorous standards, ensuring that they can withstand demanding conditions without failure. This focus on safety is crucial for industries where equipment malfunctions can have serious consequences.

Conclusion

Thermoplastic hose manufacturers play a pivotal role in advancing industrial applications by providing innovative, sustainable, and reliable products that cater to a wide range of needs. Their commitment to quality and customization not only enhances the performance of various systems but also contributes to the overall efficiency and safety of industrial operations. As industries continue to evolve, the significance of thermoplastic hoses and their manufacturers will only grow, shaping the future of manufacturing and engineering across the globe.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025