335345435

Dec . 01, 2024 22:51 Back to list

teflon hose manufacturer supplier

Understanding the Role of Teflon Hose Manufacturers and Suppliers

Teflon hoses are a crucial component in various industrial applications, known for their exceptional heat resistance, chemical stability, and low friction properties. As industries ranging from food processing to pharmaceuticals require efficient and durable piping solutions, the demand for high-quality Teflon hoses has surged. This has led to the emergence of numerous Teflon hose manufacturers and suppliers that aim to meet market needs. Understanding their role can help businesses in selecting the right partners for their operations.

What is Teflon?

Teflon, a brand name for polytetrafluoroethylene (PTFE), was discovered in 1938 by Roy Plunkett. This revolutionary material is recognized for its impressive thermal properties and inert nature, making it ideal for handling a wide range of chemicals. Teflon's unique characteristics make it a preferred choice in applications that involve extreme temperatures or aggressive substances. As a result, Teflon hoses are widely used in industries such as chemical processing, pharmaceuticals, automotive, and food and beverage.

Importance of Teflon Hose Manufacturing

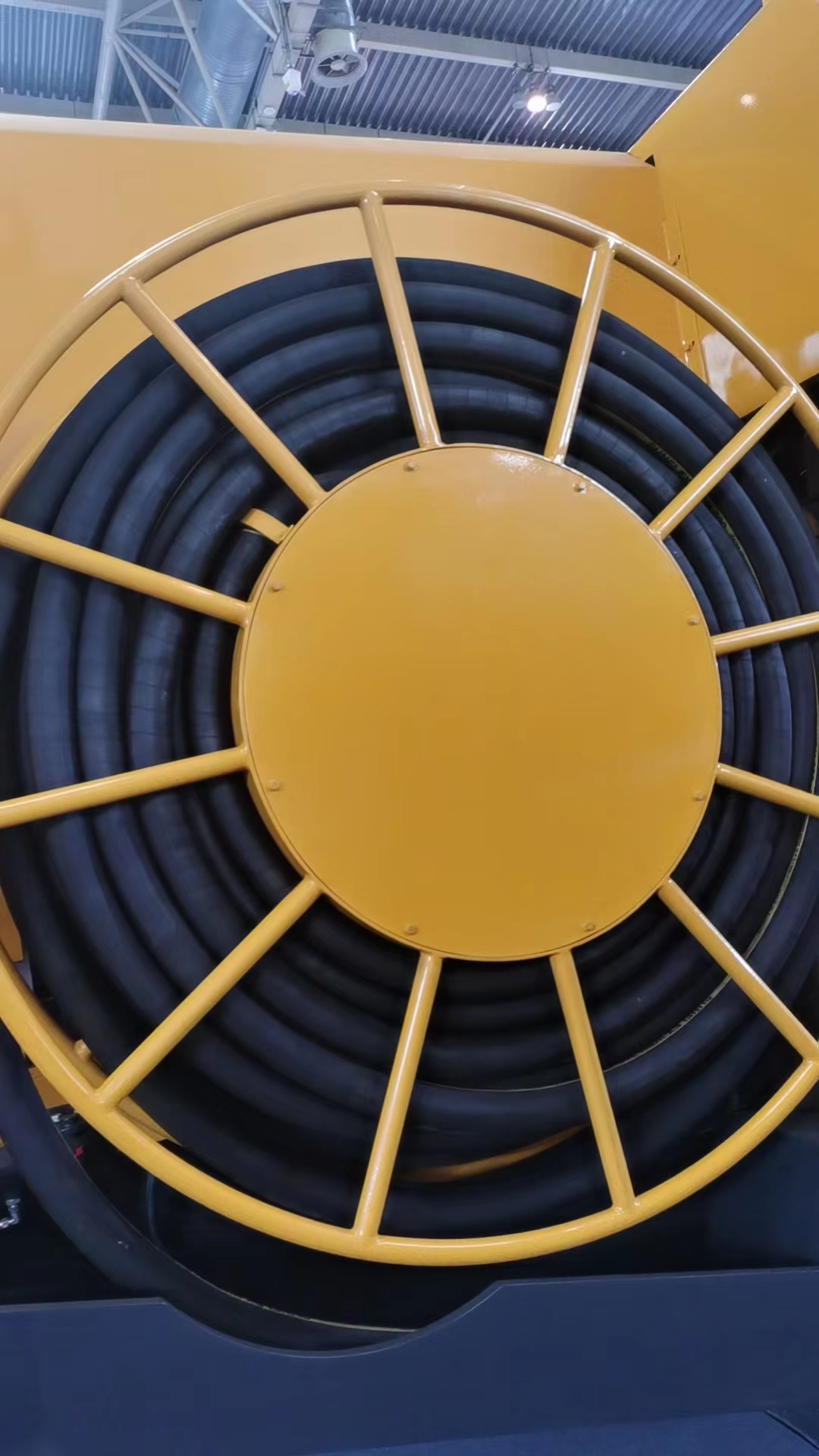

Teflon hose manufacturing involves the creation of hoses using high-quality PTFE material. Manufacturers focus on creating hoses that are not only durable but also flexible and resistant to wear and tear. The manufacturing process typically involves extruding the Teflon material into the desired hose shape and size, followed by processes like braiding or layering for added strength.

What to Look for in Teflon Hose Manufacturers

1. Quality and Certification One of the primary factors to consider when selecting a Teflon hose manufacturer is the quality of their products. Manufacturers should adhere to international quality standards, such as ISO 9001, which ensures that their products meet the necessary safety and performance criteria. Certifications that reflect compliance with food safety regulations, such as FDA approval, are also essential for companies operating in the food and beverage sector.

teflon hose manufacturer supplier

2. Customization Options Different industries have unique requirements regarding hose specifications, including diameter, length, and resistance to various chemicals. The ability to provide custom solutions is a significant advantage. Reputable manufacturers often offer flexible options to tailor hoses according to specific customer needs.

3. Durability and Performance The longevity and reliability of Teflon hoses are crucial for operational efficiency. Manufacturers should conduct rigorous testing to ensure that their hoses can withstand high pressures and temperatures while resisting chemical erosion.

4. Technical Expertise and Support Knowledgeable manufacturers can provide valuable guidance when it comes to selecting the right type of hose for particular applications. Technical support should be readily available to address concerns related to compatibility, installation, and maintenance.

The Role of Teflon Hose Suppliers

Once Teflon hoses are manufactured, suppliers play a vital role in distributing these products to end-users. They bridge the gap between manufacturers and customers, ensuring that the right products are delivered promptly. A reliable supplier should have a strong inventory of various hose types to cater to diverse industries. They often provide additional services such as packaging, shipping, and logistics support.

Conclusion

Teflon hoses are indispensable in today's industrial landscape, and the role of Teflon hose manufacturers and suppliers is critical in ensuring that businesses have access to high-quality, durable, and reliable products. When choosing a manufacturer or supplier, it is essential to consider factors such as quality certifications, customization capabilities, product durability, and the level of technical support offered. By partnering with the right Teflon hose manufacturer and supplier, companies can enhance their operational efficiency and ensure compliance with industry standards.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025