335345435

Nov . 05, 2024 22:28 Back to list

Top Manufacturers of Spiral Hydraulic Hoses for Industrial Applications and Solutions

Exploring Spiral Hydraulic Hose Manufacturers A Comprehensive Overview

In the world of industrial applications, hydraulic hoses play a pivotal role, ensuring the efficient transfer of fluids in a multitude of systems. Among the various types of hydraulic hoses available, spiral hydraulic hoses have gained significant attention due to their robustness and ability to withstand high pressure and demanding environments. This article delves into the realm of spiral hydraulic hose manufacturers, exploring their products, technological advancements, and the importance of selecting the right manufacturer for specific needs.

Understanding Spiral Hydraulic Hoses

Spiral hydraulic hoses are characterized by their unique construction, which typically involves multiple layers of high-strength reinforcement. These hoses are designed to handle high-pressure situations, making them ideal for industries such as construction, mining, and manufacturing. Their spiral construction provides enhanced flexibility and kink resistance, enabling them to perform efficiently in complex routing applications.

Manufacturers of spiral hydraulic hoses utilize advanced materials and engineering techniques to ensure that their products meet stringent industry standards. Commonly made from synthetic rubber and reinforced with steel wire, these hoses exhibit excellent durability and resistance to abrasion, temperature fluctuations, and corrosive substances.

The Role of Manufacturers

The choice of manufacturer can significantly influence the quality and performance of the hydraulic hoses. A reputable spiral hydraulic hose manufacturer not only provides products that meet industry specifications but also offers comprehensive support and guidance throughout the selection and installation processes.

When selecting a manufacturer, it is essential to consider several key factors

1. Quality Assurance Manufacturers should adhere to international quality standards, such as ISO certification. These standards ensure that the hoses produced are reliable, safe, and capable of performing under the specified conditions.

2. Material Selection The quality of materials used in manufacturing spiral hydraulic hoses directly impacts their performance. Renowned manufacturers often invest in high-grade raw materials to enhance the longevity and reliability of their products.

spiral hydraulic hose manufacturers

3. Innovation and Technology The best manufacturers continuously research and develop new technologies to improve their product offerings. This may include advancements in hose design, better reinforcement techniques, or the use of innovative materials that offer superior performance.

4. Customization Options Industries have diverse requirements, and a one-size-fits-all approach rarely suffices. Leading manufacturers often provide customization options, allowing clients to specify hose lengths, diameters, pressure ratings, and other crucial factors.

5. Customer Support and Services From initial consultation to post-purchase support, a manufacturer’s customer service can make a significant difference. Look for manufacturers that offer detailed product information, installation guidance, and proactive after-sales support.

Notable Spiral Hydraulic Hose Manufacturers

Several manufacturers have established themselves as leaders in the spiral hydraulic hose market. Companies such as Parker Hannifin, Gates, and Eaton are renowned for their innovative product lines and commitment to quality. These manufacturers have dedicated facilities for research and development, ensuring that they stay at the cutting edge of hydraulic technology.

Parker Hannifin, for example, offers a wide range of spiral hydraulic hoses tailored for various applications, including heavy-duty and high-pressure scenarios. Their extensive distribution network ensures that customers can easily access their products worldwide.

Gates is another prominent player known for their advanced hose technologies. They have developed hoses that not only meet rigorous performance standards but also offer enhanced flexibility and reduced weight, making them ideal for modern hydraulic systems.

Conclusion

As industries continue to evolve, the demand for high-quality hydraulic hoses is expected to rise. Spiral hydraulic hose manufacturers play a crucial role in meeting this demand by providing products that offer safety, performance, and reliability. By understanding the importance of selecting the right manufacturer, businesses can ensure they invest in durable and efficient solutions that support their operational needs. As the market becomes increasingly competitive, those manufacturers that prioritize innovation, quality, and customer service will undoubtedly stand out in the sector. Investing in the right spiral hydraulic hoses from reputable manufacturers is not just a choice; it’s a strategic decision that can impact the efficiency and success of various industrial operations.

-

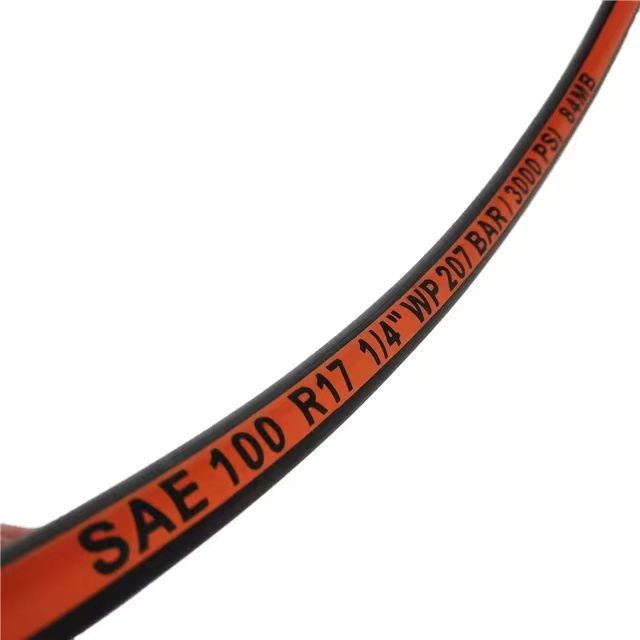

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025