335345435

Oct . 22, 2024 10:35 Back to list

sae100r2at hydraulic hose manufacturers

Understanding SAE 100R2AT Hydraulic Hose Manufacturers

When it comes to hydraulic systems, the efficiency and safety of the components are paramount. One of the vital components in these systems is the hydraulic hose, and among the various standards for these hoses, the SAE 100R2AT specification stands out. This article will explore the significance of SAE 100R2AT hydraulic hoses, the manufacturing process, and the manufacturers that provide these essential components.

What is SAE 100R2AT?

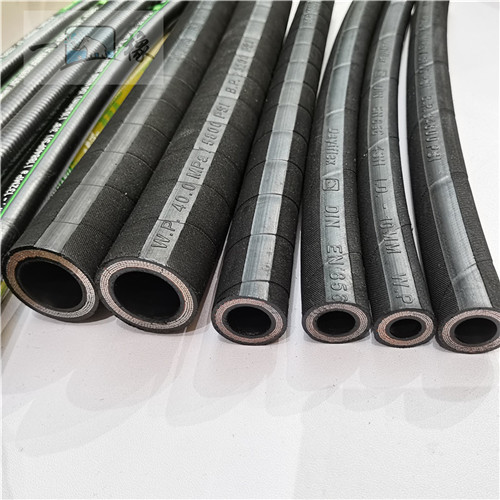

SAE 100R2AT is a standard set by the Society of Automotive Engineers (SAE) that defines the specifications for a specific type of hydraulic hose. This hose is designed to operate under high pressures and is predominantly used in hydraulic applications involving oil or water-based fluids. The R2 designation indicates its construction as a two-wire braided hose, which enhances its strength and flexibility. The AT suffix signifies that it is suitable for use with hydraulic systems, making it ideal for various applications in industries such as construction, agriculture, and manufacturing.

Key Features of SAE 100R2AT Hoses

1. High-Pressure Rating SAE 100R2AT hoses can typically handle pressures up to 4000 psi, making them suitable for heavy-duty applications.

2. Durability These hoses are constructed with reinforced materials that provide exceptional resistance to abrasion, weathering, and exposure to chemicals, ensuring a long service life.

4. Temperature Resistance They can operate effectively within a temperature range of -40°F to 212°F (-40°C to 100°C), allowing them to function in various environmental conditions.

sae100r2at hydraulic hose manufacturers

The Manufacturing Process

Manufacturing SAE 100R2AT hoses involves several critical steps to ensure that the end product meets rigorous industry standards. The process begins with selecting high-quality raw materials, including synthetic rubber and steel wire. The rubber is extruded to form the inner tube, which is then reinforced with two layers of steel wire braiding. Once the hose is assembled, the outer layer is also applied to protect against environmental factors.

The hoses undergo rigorous testing to verify their pressure ratings, durability, and flexibility. Manufacturers often invest in advanced technology and quality control processes to meet or exceed the specifications laid out in the SAE 100R2AT standard. This commitment to quality is crucial for ensuring that the hoses can withstand the demanding conditions of hydraulic systems.

Leading Manufacturers

The demand for SAE 100R2AT hydraulic hoses has led to the emergence of numerous manufacturers worldwide. Some reputable companies specialize in producing high-performance hydraulic hoses. These manufacturers often prioritize quality control, customer service, and innovative designs to meet the evolving needs of their clients.

When selecting a manufacturer for SAE 100R2AT hoses, it is essential to consider factors such as their reputability, product range, compliance with industry standards, and customer feedback. Leading manufacturers are usually ISO-certified and adhere to stringent quality management systems, ensuring that their products are reliable and durable.

Conclusion

In conclusion, SAE 100R2AT hydraulic hoses are crucial components in hydraulic systems, combining strength, flexibility, and versatility. As industries continue to demand high-quality solutions for their hydraulic applications, reputable manufacturers will play a vital role in ensuring the availability of reliable and durable hoses, contributing to the efficiency and safety of hydraulic systems worldwide. Whether in construction, agriculture, or manufacturing, the right hydraulic hoses can make all the difference in operational performance.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025