335345435

Nov . 08, 2024 03:31 Back to list

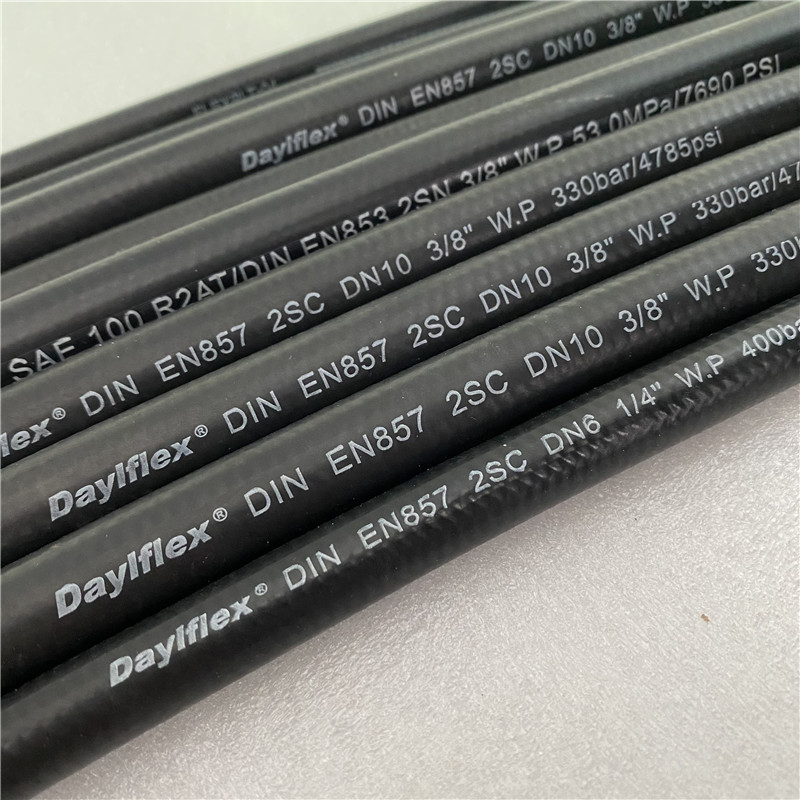

High-Performance Hydraulic Hose for Heavy-Duty Applications and Robust Flexibility

Understanding SAE 100R13 A Comprehensive Overview

In the realm of hydraulic hoses, SAE 100R13 is a pivotal standard that plays a crucial role in various industrial applications. This standard is established by the Society of Automotive Engineers (SAE), which outlines the specifications for hydraulic hoses that are designed to operate under high pressure. Understanding SAE 100R13 is essential for engineers, manufacturers, and users of hydraulic equipment, as it guarantees safety, reliability, and efficiency in hydraulic systems.

What is SAE 100R13?

SAE 100R13 is a standard specification for high-pressure hydraulic hoses reinforced with four steel wire spirals. It is designed for use in hydraulic systems where fluids are conveyed under high pressure. The construction of SAE 100R13 allows it to endure extreme conditions and environments, making it suitable for a wide range of applications, including construction, agricultural machinery, mining, and industrial equipment.

The primary attributes of SAE 100R13 hoses include - High Pressure Capability These hoses can handle pressures up to 420 bar (6090 PSI), depending on the hose size, ensuring they can work effectively in demanding situations. - Temperature Resistance They typically operate in temperature ranges from -40°C to +100°C (-40°F to +212°F), accommodating various fluid types and operational conditions. - Reinforced Design The four-wire spiral reinforcement provides excellent structural integrity, helping the hose withstand bending, flexing, and crushing.

Construction and Materials

The construction of SAE 100R13 hoses involves high-quality materials that ensure durability and performance. The inner lining is usually made of synthetic rubber, which is compatible with a variety of hydraulic fluids, including petroleum-based and water-based fluids. This inner tube is reinforced with four layers of high-tensile steel wire spirals, creating a robust framework that allows the hose to handle high pressure without deformation.

sae100r13

An outer layer of synthetic rubber provides additional protection against environmental factors such as abrasion, heat, and ozone. This outer cover is designed to withstand various external conditions, thus prolonging the hose's life cycle.

Applications of SAE 100R13

SAE 100R13 hoses are versatile and find applications in numerous industrial sectors. Some common uses include - Construction Equipment Used in hydraulic excavators, loaders, and cranes, these hoses are essential for transferring hydraulic fluids that power machinery. - Agricultural Machinery Tractors and harvesters rely on SAE 100R13 hoses to operate hydraulic systems for lifting and moving crops. - Mining Operations High-pressure hoses are critical for mining equipment, which requires robust hydraulic systems to operate machinery for digging and transporting materials. - Industrial Processes Many manufacturing processes utilize hydraulic machinery that depends on SAE 100R13 hoses for efficiency and productivity.

Advantages of Using SAE 100R13

Utilizing SAE 100R13 hoses offers several advantages - Reliability The robust construction ensures that these hoses can maintain their integrity under high pressure, minimizing the risk of failure. - Versatility Their ability to function with various hydraulic fluids makes them suitable for a wide range of applications across different industries. - Safety Following SAE guidelines ensures that the hoses meet stringent safety standards, reducing the likelihood of catastrophic failures that could lead to injuries or machinery damage.

Conclusion

In summary, SAE 100R13 is a cornerstone standard for high-pressure hydraulic hoses that are integral to many industrial operations. Its design and specifications ensure that it can withstand challenging conditions while providing reliable performance. For engineers, manufacturers, and users alike, understanding the characteristics and applications of SAE 100R13 is essential for selecting the right hydraulic components and ensuring the efficiency and safety of hydraulic systems. As industries continue to evolve, the importance of robust hydraulic solutions, underscored by such standards, will only grow, highlighting the relevance of SAE 100R13 in the modern industrial landscape.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025