335345435

Nov . 08, 2024 14:26 Back to list

sae100r12 factories

Understanding SAE 100R12 Hydraulic Hose Factories and Manufacturing

SAE 100R12 is a specific standard for hydraulic hoses, primarily used in high-pressure applications. This standard is crucial for industries that rely on hydraulic systems, such as construction, agriculture, and manufacturing. The design and manufacturing of SAE 100R12 hoses involve specific materials and processes to ensure safety, reliability, and performance.

Overview of SAE 100R12 Specifications

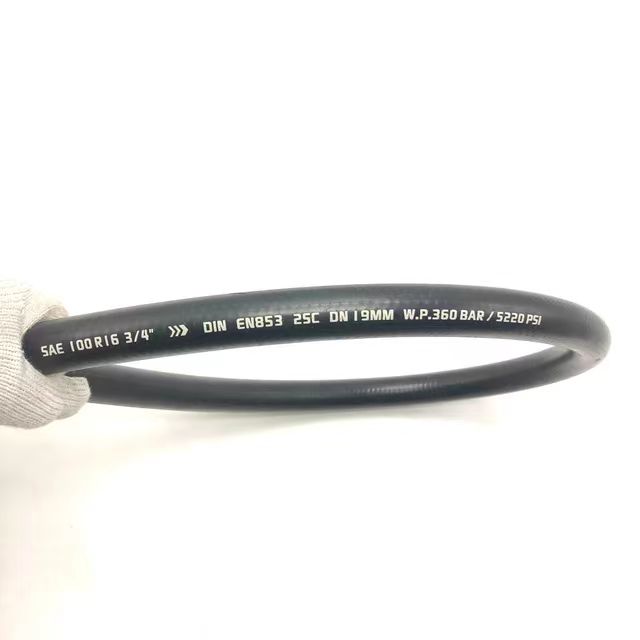

SAE 100R12 hoses are characterized by their ability to handle high pressures, often up to 4,000 psi. These hoses are constructed from a synthetic rubber inner tube, which is reinforced with multiple layers of high-tensile steel wire braided or spiral-wrapped. This design provides significant strength and flexibility, crucial for various hydraulic applications. The outer cover is typically made from abrasion-resistant materials to prolong the hose's lifespan, making it suitable for rugged environments.

The Role of Factories in Manufacturing SAE 100R12 Hoses

Producing SAE 100R12 hoses requires specialized factories equipped with advanced machinery and skilled labor. The manufacturing process involves several critical steps

1. Material Selection The first step in the manufacturing process is selecting high-quality materials. The inner tube must be made of a rubber compound that can withstand intense pressure and is resistant to hydraulic fluids. The wire used for reinforcement is usually high-tensile steel, ensuring maximum strength.

2. Rubber Formulation and Mixing The chosen rubber compounds are mixed with additives to enhance their properties, such as flexibility, durability, and resistance to heat and chemicals.

3. Extrusion The rubber mixture is then extruded to form the inner tube of the hose. This process requires precision and control to ensure the right thickness and smooth finish.

4. Reinforcement After the inner tube is formed, layers of steel wire are applied. For SAE 100R12 hoses, a spiral wound configuration is common, providing superior pressure resistance.

sae100r12 factories

5. Covering The outer rubber cover is applied, which protects the internal components from external wear and tear. This cover is also made resistant to abrasion, weather, and ozone to enhance the hose's overall durability.

6. Curing The hose assembly then undergoes curing, a crucial step where the rubber is subjected to heat to solidify and strengthen the material. This process ensures that the hoses maintain their integrity under pressure.

7. Testing and Quality Control Once manufactured, the hoses are rigorously tested to ensure they meet the SAE 100R12 specifications. This includes pressure testing, impulse testing, and examining for any defects. Factories must adhere to strict quality control measures to prevent failures in the field.

The Importance of Industry Standards

SAE (Society of Automotive Engineers) standards, including SAE 100R12, are vital in the manufacturing of hydraulic hoses. These standards ensure that products are safe, reliable, and perform as expected in demanding applications. Factories must comply with these standards to ensure their products are acceptable in the market.

Global Manufacturing Landscape

The production of SAE 100R12 hoses is not limited to one region; factories around the world are involved in this industry. Countries such as the United States, Germany, China, and Japan have established manufacturing facilities due to their technological expertise and significant demand for hydraulic systems. Each factory may implement different production techniques and standards, which can influence the final product's quality and performance.

Conclusion

SAE 100R12 hoses play a crucial role in the functioning of hydraulic systems across various industries. Understanding the manufacturing process and the importance of high-quality materials is essential for anyone involved in selecting or using hydraulic hoses. Factories that produce these hoses must adhere to stringent industry standards to ensure safety and reliability. As industries continue to evolve, the demand for high-performance hydraulic hoses will only increase, making the role of manufacturing facilities more critical than ever. Their commitment to quality and innovation will shape the future of hydraulic systems worldwide.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025