335345435

Oct . 09, 2024 15:24 Back to list

Flexible LPG Hose for Safe and Efficient Gas Transfer Solutions

Understanding Rubber Hoses for LPG Safety, Applications, and Maintenance

Rubber hoses are essential components in various industries, and one of their significant applications is in the handling of liquefied petroleum gas (LPG). These hoses are designed to transport gas safely from one point to another, ensuring efficient and secure operations in residential, commercial, and industrial settings. This article will delve into the features, applications, safety considerations, and maintenance of rubber hoses for LPG.

Features of Rubber Hoses for LPG

Rubber hoses designed for LPG are typically made from synthetic rubber compounds that can withstand the unique properties of gas. They are built to be flexible yet durable, ensuring they can handle high pressures without bursting. Additionally, these hoses have excellent resistance to temperature fluctuations and environmental factors, which is crucial given that LPG can be transported in varying climates. The inner lining of the hose is often designed specifically for gas transport, minimizing the risk of gas leakage and ensuring that the hose maintains its integrity over time.

Moreover, the outer layer of these hoses is usually reinforced with wire braiding to enhance their strength. This reinforcement helps the hose withstand mechanical stresses and prevents it from kinking or collapsing during use. Furthermore, rubber hoses for LPG are often marked with safety certifications, indicating they meet the regulatory requirements for gas transport.

Applications of Rubber Hoses for LPG

Rubber hoses for LPG are used in various applications. In residential settings, they are commonly found in gas grills, heaters, and cooking appliances. Businesses such as restaurants and catering services also rely on these hoses to ensure a constant supply of gas for cooking and heating.

rubber hose for lpg

In industrial contexts, rubber hoses play a vital role in large-scale operations, such as transporting LPG from storage tanks to processing facilities. Additionally, they are used in bulk transport vehicles that move LPG over long distances. Their versatility and robustness make them an indispensable tool across multiple sectors.

Safety Considerations

Safety is paramount when dealing with LPG, and proper use of rubber hoses is crucial in minimizing risks. Users must ensure that the hoses are rated for the pressure and temperature they will encounter. Regular inspections are necessary to identify signs of wear, such as cracks, bulges, or leaks. If any damage is found, the hose should be replaced immediately.

It is also essential to ensure that the fittings on the hoses are properly secured to prevent leaks. Care should be taken during both the installation and the disconnection of hoses to avoid accidents. Furthermore, hoses should be kept away from sharp objects or highly abrasive surfaces to prevent damage.

Maintenance of Rubber Hoses

To maintain the integrity and longevity of rubber hoses for LPG, users should follow a routine maintenance schedule. Cleaning the hoses regularly helps prevent the buildup of residue that can cause deterioration. It's advisable to store hoses in a cool, dry place, away from direct sunlight, which can degrade rubber over time.

In conclusion, rubber hoses for LPG are vital for safe and effective gas handling in various applications. By understanding their features, applications, safety considerations, and maintenance practices, users can ensure they are using these hoses properly and efficiently, thereby minimizing risks and maximizing performance. Proper care and attention to these aspects will lead to a safer environment in both residential and industrial LPG applications.

-

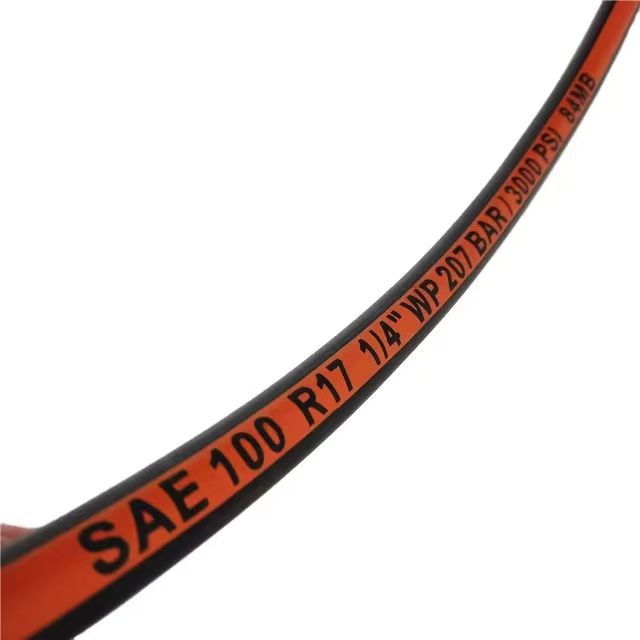

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025