335345435

Oct . 21, 2024 06:17 Back to list

Top One Wire Braided Hydraulic Hose Manufacturers for Reliable Performance and Quality

Understanding One Wire Braided Hydraulic Hose Manufacturers

In the realm of industrial applications, hydraulic hoses are pivotal for fluid power systems. Among the selection available, one wire braided hydraulic hoses stand out for their robustness and flexibility. These hoses are widely used across various sectors, including construction, agriculture, and manufacturing, due to their efficient transfer of hydraulic fluids under high pressure. This article delves into the significance of one wire braided hydraulic hoses and the manufacturers who produce them.

What is a One Wire Braided Hydraulic Hose?

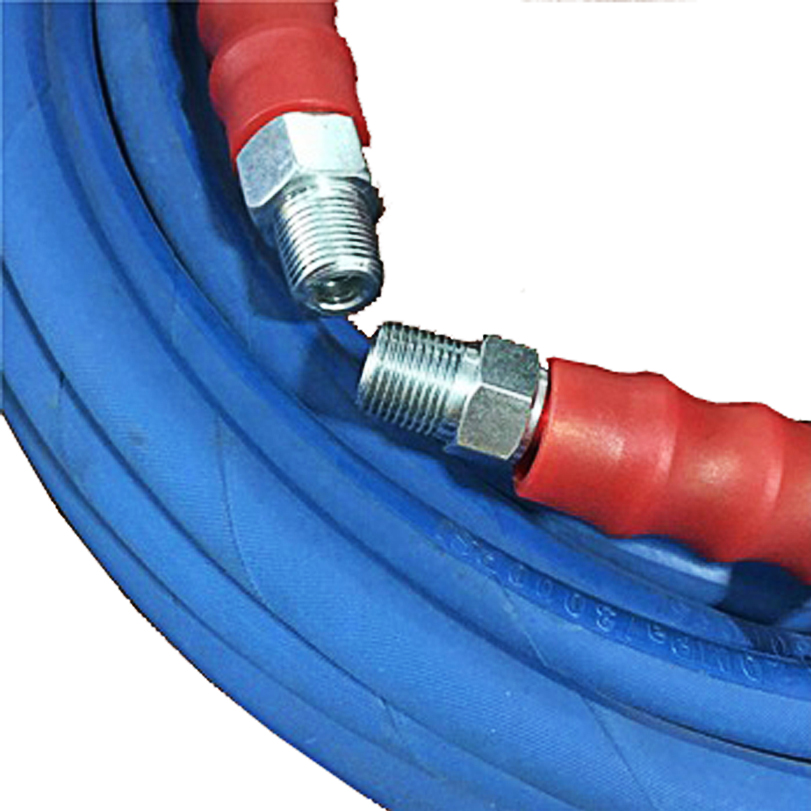

A one wire braided hydraulic hose is designed with a single layer of braided steel wire reinforcement surrounding its inner rubber tube. This construction provides the hose with significant strength and flexibility, allowing it to withstand high pressures, usually ranging from 3000 to 6000 PSI, depending on the diameter and construction. The ability of this type of hose to handle extreme conditions makes it a favored choice for various hydraulic systems.

One wire braided hoses are particularly advantageous for applications that require a high degree of flexibility while still maintaining pressure resistance. They are commonly used for applications such as hydraulic lifts, industrial machinery, and agricultural equipment where movement and vibration are factors that could affect hose performance.

The Role of Manufacturers

Manufacturers of one wire braided hydraulic hoses play a critical role in ensuring the availability and quality of these essential products. They engage in various processes, from sourcing raw materials to the production and distribution of the hoses. Quality control is paramount in this industry, as any defect in the hose can lead to catastrophic failures in hydraulic systems. Therefore, reputable manufacturers adhere to stringent standards and certifications, ensuring their products meet industry requirements.

When choosing a manufacturer, several factors come into play

1. Quality Assurance Manufacturers should have a reputation for producing high-quality hoses. Certifications such as ISO 9001, which ensures a commitment to quality management systems, can be a red flag indicator.

one wire braided hydraulic hose manufacturers

2. Material Sourcing The quality of raw materials, including rubber compounds and steel wires, directly affects the hose’s performance and durability. Leading manufacturers often have robust procurement processes in place to source high-grade materials.

3. Technology and Equipment Modern manufacturers utilize advanced technology and equipment to enhance production efficiency and quality. The use of automation and sophisticated machinery can lead to consistent product quality and lower production costs.

4. Customization Options Different applications require different specifications. A dependable manufacturer offers customization options, allowing customers to specify hose lengths, diameters, and even unique fittings that meet specific operational needs.

5. Customer Support and Service Establishing a partnership with a reliable manufacturer means having access to excellent customer support. Whether it’s pre-sales assistance, product training, or post-sale service, having responsive support is crucial for businesses reliant on hydraulic hoses.

Emerging Trends and Innovations

The hydraulic hose industry is continually evolving, and manufacturers are adapting to meet new demands and challenges. An increasing focus on sustainability has led manufacturers to explore eco-friendly materials and processes. Additionally, advancements in materials science have resulted in hoses that offer improved performance characteristics such as enhanced abrasion resistance and lower weight.

Digital technologies also play a role. Manufacturers are beginning to incorporate smart technology into hydraulic hoses, enabling real-time monitoring of performance metrics, which can preemptively identify potential issues before they result in failure.

Conclusion

One wire braided hydraulic hoses are integral components in numerous industries, providing reliable performance under high-pressure situations. The manufacturers behind these hoses play a vital role in ensuring quality and reliability through rigorous production standards and innovative practices. As industrial needs evolve, so do the solutions provided by these manufacturers, highlighting the importance of selecting a trusted and forward-thinking partner in this essential supply chain. Whether you are in construction, agriculture, or any other sector utilizing hydraulic systems, understanding the capabilities and innovations of one wire braided hydraulic hose manufacturers can empower your operations and enhance overall productivity.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025