335345435

Nov . 11, 2024 10:52 Back to list

oil suction and discharge rubber hose manufacturers

An Overview of Oil Suction and Discharge Rubber Hose Manufacturers

In the dynamic world of industrial operations, the transportation of liquids, especially petroleum products, is crucial. Oil suction and discharge rubber hoses play a pivotal role in this process. Designed to effectively handle the transfer of oil, these hoses are engineered to withstand high pressure, ensuring the safe and efficient movement of fluids. This article delves into the significance of these hoses, the features that define them, and a glimpse into the manufacturers who produce them.

The Importance of Oil Suction and Discharge Hoses

Oil suction and discharge hoses are essential components in various industries, including oil and gas, marine, and petrochemical sectors. These hoses are used for loading and unloading oil from tankers, tank farms, and during drilling operations. Their robust construction is vital to prevent leaks, spills, and potential hazards that can arise from transporting flammable materials.

The demand for high-quality hoses is paramount in maintaining safety standards and operational efficiency. Inadequate or damaged hoses can lead to severe repercussions not only in terms of financial loss but also environmental damage. This highlights the necessity for reliable manufacturers that prioritize quality and safety in their production processes.

Key Features of Quality Hoses

When selecting oil suction and discharge rubber hoses, several features should be considered

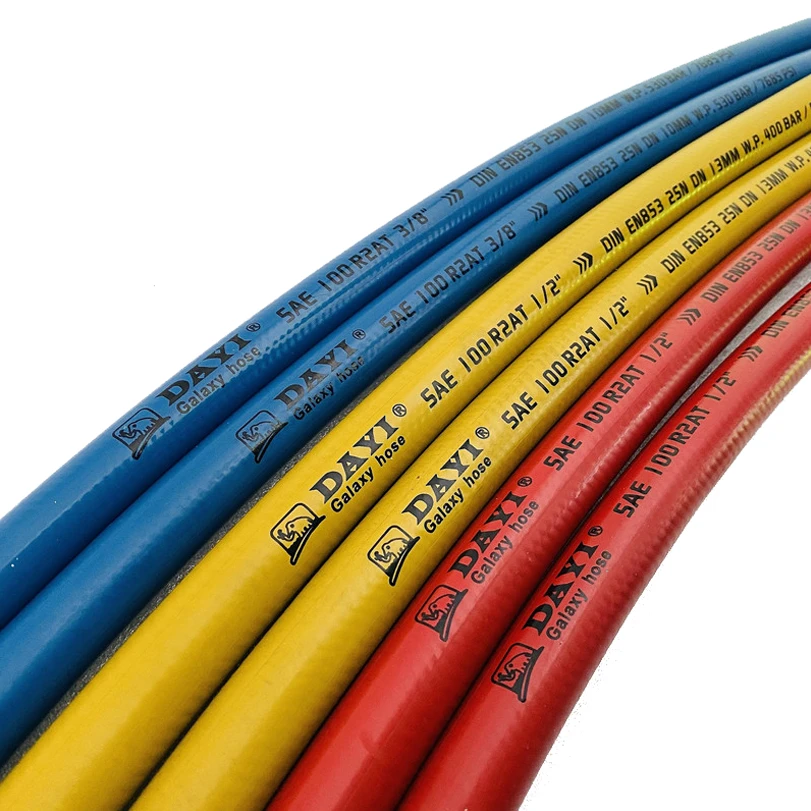

1. Material Composition The best hoses are made from durable rubber compounds that can handle the abrasiveness and corrosiveness of oil. Reinforcements, such as textiles or steel wire, enhance their strength and flexibility.

2. Pressure Rating These hoses must be rated for the specific pressure conditions under which they will operate. High-pressure ratings ensure that the hose can withstand the force exerted by the fluid, minimizing the risk of rupture.

3. Temperature Resistance Oil temperature can fluctuate significantly during transportation. Manufacturers must ensure that their hoses can withstand both low and high-temperature extremes without degrading.

oil suction and discharge rubber hose manufacturers

4. Size and Compatibility Hoses come in various diameters and lengths. Manufacturers must adhere to industry standards to ensure compatibility with pumps, valves, and other equipment.

5. Flexible Design Flexibility is crucial for ease of handling and installation. A high-quality hose should be flexible enough to navigate through tight spaces while maintaining its structural integrity.

Leading Manufacturers in the Industry

The market for oil suction and discharge rubber hoses is populated by numerous manufacturers, each vying to establish a reputation for quality and reliability. Companies often emphasize research and development to innovate their products continually.

1. Continental Known for its extensive range of industrial hose products, Continental specializes in high-performance rubber hoses designed to meet rigorous industry standards. Their commitment to innovation makes them a leader in the sector.

2. Goodyear With a long-standing history in rubber manufacturing, Goodyear produces a variety of hoses for oil and gas applications. Their high-quality products are recognized globally and are synonymous with reliability.

3. Parker Hannifin Parker offers a comprehensive portfolio of hoses and fittings tailored for the oil and gas industry. Their focus on safety and performance makes them a preferred choice for many businesses.

4. Saeed Rubber A regional player, Saeed Rubber focuses on producing high-quality oil hoses customized to meet local and international standards, emphasizing customer satisfaction and product longevity.

Conclusion

Oil suction and discharge rubber hose manufacturers play an indispensable role in the safe and efficient transport of petroleum products across various industries. With an acute focus on quality, durability, and safety features, these manufacturers ensure that companies can operate with confidence. As global demands for oil continue to rise, the significance of reliable and innovative hose technology cannot be overstated, setting a benchmark in the industry for future advancements. As we look towards a more sustainable era, the evolution of these hoses will also include innovations that align with environmental responsibility.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025