335345435

Oct . 12, 2024 21:10 Back to list

Oil Suction and Discharge Hose Manufacturing Solutions for Industrial Applications

The Role of Oil Suction and Discharge Rubber Hoses in the Industrial Sector

In today's fast-paced industrial landscape, the need for efficient material handling solutions has become increasingly critical. One such solution lies in the use of oil suction and discharge rubber hoses, which play a vital role in various industries including petroleum, construction, and agriculture. This article aims to shed light on the importance, manufacturing processes, and applications of these essential components.

Importance of Oil Suction and Discharge Rubber Hoses

Oil suction and discharge hoses are crucial for the safe and efficient transfer of oil and other petroleum products. Designed to withstand high pressures and extreme temperatures, these hoses mitigate the risks associated with transferring potentially hazardous materials. Their flexible nature allows for easy maneuverability and installation in tight or complex environments, making them an indispensable tool in many industrial applications.

The manufacturing of oil suction and discharge hoses involves the use of high-quality rubber compounds, often reinforced with steel wire or fabric to enhance durability and flexibility. The hoses are designed to resist abrasion, aging, and various chemicals, ensuring a long service life and reliable performance. This adaptability makes them suitable for transferring not just crude oil, but also hydraulic fluids, chemical solvents, and liquid gas.

Manufacturing Process

The manufacturing of oil suction and discharge rubber hoses is a sophisticated process that combines advanced technology with tried-and-true techniques. The first step begins with the selection of raw materials, which include high-quality rubber compounds that can withstand the demanding environments they will face. Manufacturers often opt for materials like neoprene or EPDM (Ethylene Propylene Diene Monomer) for their excellent chemical resistance and stretchability.

Once the materials are prepared, they undergo a series of processes including extrusion and calendaring. The extrusion process involves shaping the rubber into a tubular form, while calendaring helps to produce the lining that provides additional protection against wear and tear. Next, reinforcing materials such as steel wire or textile fibers are integrated into the hose structure to enhance its tensile strength.

oil suction and discharge rubber hose factory

After assembling the hose, it is subjected to curing or vulcanization, a critical step that involves heating the rubber to create strong bonds between its molecules. This process enhances the strength and flexibility of the hose, making it suitable for various applications. Finally, quality control measures are implemented to test the hoses for their pressure resistance and leakage, ensuring only the highest quality products reach the market.

Applications

The applications of oil suction and discharge rubber hoses are vast and varied. In the petroleum industry, they are predominantly used for the transfer of crude oil from extraction sites to refineries and storage facilities. Their resistance to high pressure makes them ideal for this application, where any failure could result in catastrophic environmental consequences.

In agricultural settings, these hoses are essential for the transfer of fertilizers and pesticides, helping to optimize crop production while ensuring safety. Construction industries also rely on these hoses for transferring fuels to heavy machinery and equipment, facilitating a smoother workflow on job sites.

Moreover, in the marine sector, oil suction and discharge hoses are employed for transferring fuels between ships and shore facilities, adhering to strict regulations to prevent spills and environmental damage.

Conclusion

Oil suction and discharge rubber hoses are a vital component of modern industrial operations. Their robust design, coupled with advanced manufacturing processes, ensures their reliability and efficiency across various applications. As industries continue to evolve and demand safer and more effective ways to handle materials, these hoses will undoubtedly play a pivotal role in enhancing operational performance and ensuring environmental protection. Manufacturers and users alike must continue to prioritize the quality and safety of these hoses to meet the growing challenges of the industrial sector.

-

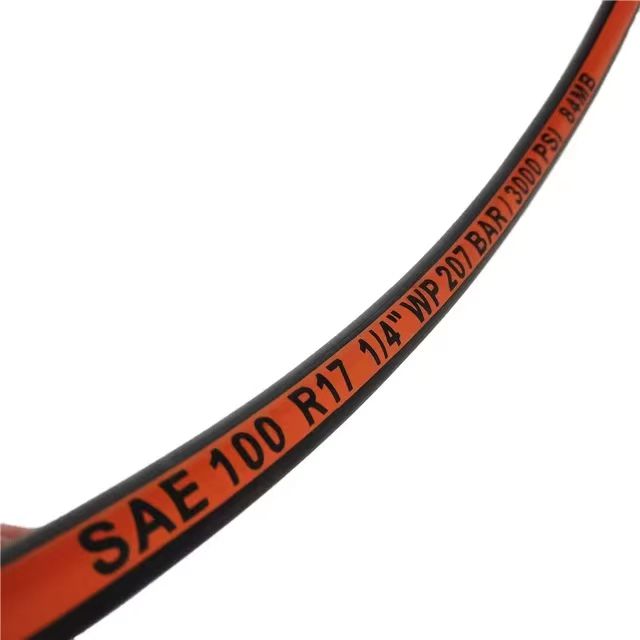

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025