335345435

Dec . 04, 2024 13:37 Back to list

OEM Custom Steel Wire Wrapped Hydraulic Hose Manufacturer and Supplier

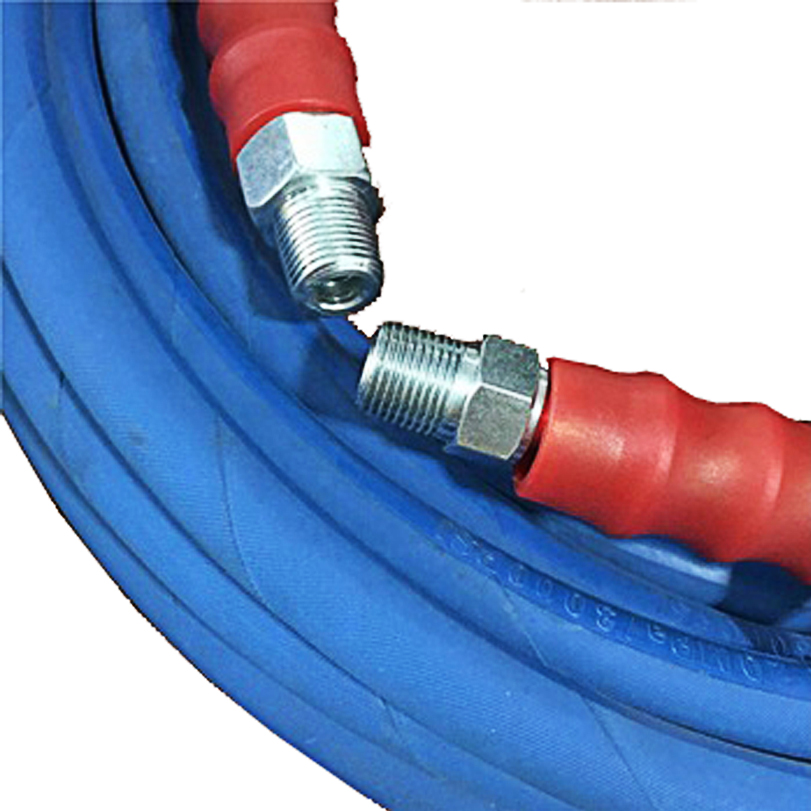

Understanding OEM Wrapped Cover Steel Wire Spiral Hydraulic Hoses A Sneak Peek into Factory Operations

Hydraulic hoses are essential components in various industrial applications, providing the necessary flexibility, strength, and durability to transport hydraulic fluids. Among the different types of hydraulic hoses, the OEM wrapped cover steel wire spiral hydraulic hose stands out due to its unique construction and applications. In this article, we will explore the characteristics, benefits, and manufacturing processes involved in fabricating these hoses, providing insights into factory operations.

What is an OEM Wrapped Cover Steel Wire Spiral Hydraulic Hose?

OEM stands for Original Equipment Manufacturer, denoting products that are made to the specifications of a particular manufacturer. Wrapped cover steel wire spiral hydraulic hoses are constructed with multiple layers of steel wire spirals, which provide exceptional pressure resistance and durability. The “wrapped cover” refers to an outer layer that protects the inner layers from environmental elements and abrasions, extending the hose's overall lifespan.

These hoses are designed to handle high-pressure applications, typically found in industries such as construction, agriculture, and manufacturing. They are capable of withstanding pressures of up to 4,000 PSI or more, making them ideal for hydraulic systems that require reliable fluid transfer under demanding conditions.

Key Features and Benefits

1. High Pressure Resistance The steel wire spiral construction allows these hoses to endure extreme pressures, ensuring safety and reliability in hydraulic systems.

2. Durability The wrapped cover adds an additional layer of protection against abrasion, cuts, and external damage, thus enhancing the hose's lifespan.

3. Flexibility Despite their robust construction, OEM wrapped cover hoses maintain a level of flexibility that permits easy routing in tight spaces without compromising their integrity.

5. Customizability OEM manufacturers can tailor the hoses to meet specific needs, including variations in length, diameter, and pressure ratings.

oem wrapped cover steel wire spiral hydraulic hose factory

Manufacturing Process

The manufacturing of OEM wrapped cover steel wire spiral hydraulic hoses involves several precise steps, engineered to maintain high-quality standards

1. Raw Material Selection The process begins with the selection of high-quality rubber and steel wire. The choice of materials greatly influences the performance characteristics of the final product.

2. Wire Spiral Formation Steel wires are spiraled into layers using specialized machinery. The spiral technique provides enhanced strength and resistance to pressure fluctuations.

3. Inner Tube Extrusion The inner tube is extruded from high-performance rubber, which serves as the primary conduit for hydraulic fluids. This tube is designed to be compatible with various hydraulic fluids, ensuring minimal degradation over time.

4. Layer Assembly The spiraled steel wire is combined with the inner tube, followed by the application of additional reinforcement layers if needed. This assembly is crucial in achieving the desired performance specifications.

5. Outer Layer Application The wrapped cover is applied over the assembled layers. This outer layer is typically made from a synthetic rubber compound that provides resistance to abrasion, weathering, and temperature fluctuations.

6. Curing and Testing Finally, the hose undergoes a curing process to enhance its properties. Quality control tests, including pressure tests and visual inspections, are conducted to ensure that the hoses meet all safety standards and specifications.

Conclusion

OEM wrapped cover steel wire spiral hydraulic hoses are vital in industries that demand high-performance and reliable hydraulic systems. Their robust construction, combined with superior flexibility and durability, makes them an excellent choice for high-pressure applications. Understanding the intricacies of their manufacturing process sheds light on the importance of quality materials and precise engineering in producing components that can withstand extreme operational conditions. As industries continue to evolve, the demand for such advanced hydraulic hoses is likely to grow, prompting ongoing innovations in their design and production. Whether you're in construction, manufacturing, or agriculture, investing in quality hydraulic hoses can significantly enhance operational efficiency and safety.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025