335345435

Oct . 11, 2024 18:33 Back to list

OEM Two Wire Braided High Pressure Hydraulic Hose for Reliable Performance and Durability

Understanding OEM Two Wire Braided High Pressure Hydraulic Hose

High pressure hydraulic hoses are essential components in various industrial applications, providing the necessary flexibility and strength to transmit hydraulic fluids under high pressure. Among the different types of hydraulic hoses, the OEM two wire braided high pressure hydraulic hose stands out due to its superior construction and reliability. This article delves into the features, advantages, applications, and maintenance of this robust hydraulic hose.

Features of OEM Two Wire Braided Hydraulic Hose

The OEM two wire braided high pressure hydraulic hose is engineered to handle extreme pressures while maintaining flexibility. The hose typically comprises three main components the inner tube, reinforcement layer, and outer cover.

1. Inner Tube The inner tube is usually made from synthetic rubber or thermoplastic materials, specifically designed to resist hydraulic fluids and chemicals. This core layer is crucial as it forms the barrier between the hydraulic fluid and the outside environment, preventing leaks.

2. Reinforcement Layer As the name suggests, this type of hose features two braided steel wire layers. The braiding gives it remarkable tensile strength, allowing the hose to withstand higher pressures—often exceeding 4000 PSI. The dual-layer design provides enhanced safety and durability, making it less susceptible to punctures and abrasions.

3. Outer Cover The outer layer of the hose is typically made from a durable rubber or thermoplastic material, which helps protect the hose from external factors such as weather, abrasion, and extreme temperatures. This layer ensures that the hose remains intact even in harsh working environments.

Advantages of the Two Wire Braided Design

The two wire braided construction of this hydraulic hose offers several advantages

- High Pressure Resistance As one of the critical features, the braiding allows the hose to withstand high pressures without compromising on flexibility. This is particularly important in industries where hydraulic systems need to operate under significant stress.

- Enhanced Flexibility Despite its strength, the hose remains flexible and easy to handle. This is crucial for installation in tight spaces where rigid hoses would be impractical.

- Durability The materials used in the construction of the OEM two wire braided high pressure hydraulic hose ensure a long service life. The hose is resistant to oil, water, and other fluids, protecting it from internal degradation.

- Safety Features In high-pressure applications, hose failures can lead to dangerous situations

. The robust design of the two wire braided hose minimizes the risk of burst failures, enhancing workplace safety.Applications

oem two wire braided high pressure hydraulic hose

The OEM two wire braided high pressure hydraulic hose is used across various industries, including

- Construction Hydraulic systems in construction equipment such as excavators, backhoes, and cranes rely on such hoses to operate effectively.

- Manufacturing In factories, hydraulic hoses are integral to machinery that lifts heavy materials, providing the necessary power for operations.

- Agriculture Agricultural machinery, including tractors and harvesters, often uses high pressure hydraulic hoses to maximize efficiency and performance.

- Automotive Hydraulic systems in vehicles utilize these hoses for brake lines, steering, and other applications requiring reliable fluid transfer under pressure.

Maintenance and Care

Proper maintenance of the OEM two wire braided high pressure hydraulic hose is essential for ensuring its longevity and performance. Here are some maintenance tips

1. Regular Inspections Periodically inspect the hose for signs of wear, cracking, or abrasion. Pay attention to areas where the hose bends or contacts other equipment.

2. Fluid Compatibility Ensure that the hydraulic fluids used are compatible with the hose materials to prevent degradation.

3. Avoid Overextension Do not stretch or kink the hose during operation, as this can lead to internal damage.

4. Proper Storage When not in use, store hoses in a clean, dry environment to avoid exposure to chemicals or UV light, which could deteriorate the materials.

Conclusion

The OEM two wire braided high pressure hydraulic hose exemplifies engineering excellence, combining strength, flexibility, and durability. Its applications span across multiple industries, making it a vital component in hydraulic systems. By understanding its features and maintaining it properly, users can maximize performance and safety in their hydraulic operations.

-

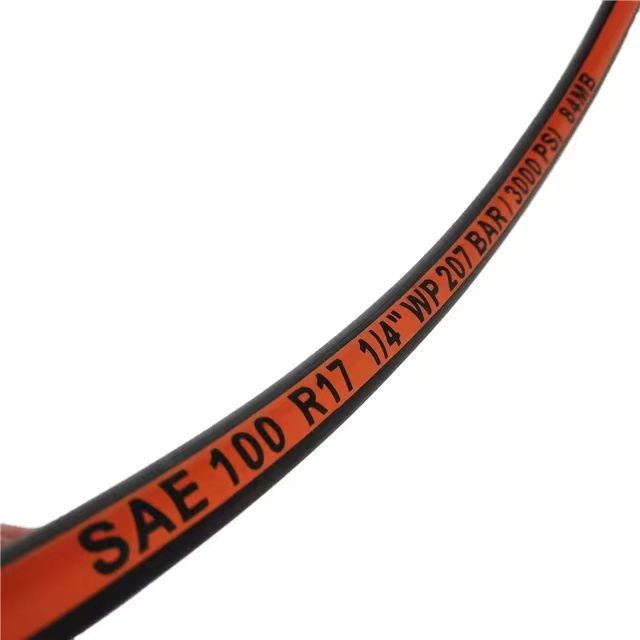

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025