335345435

Dec . 12, 2024 11:39 Back to list

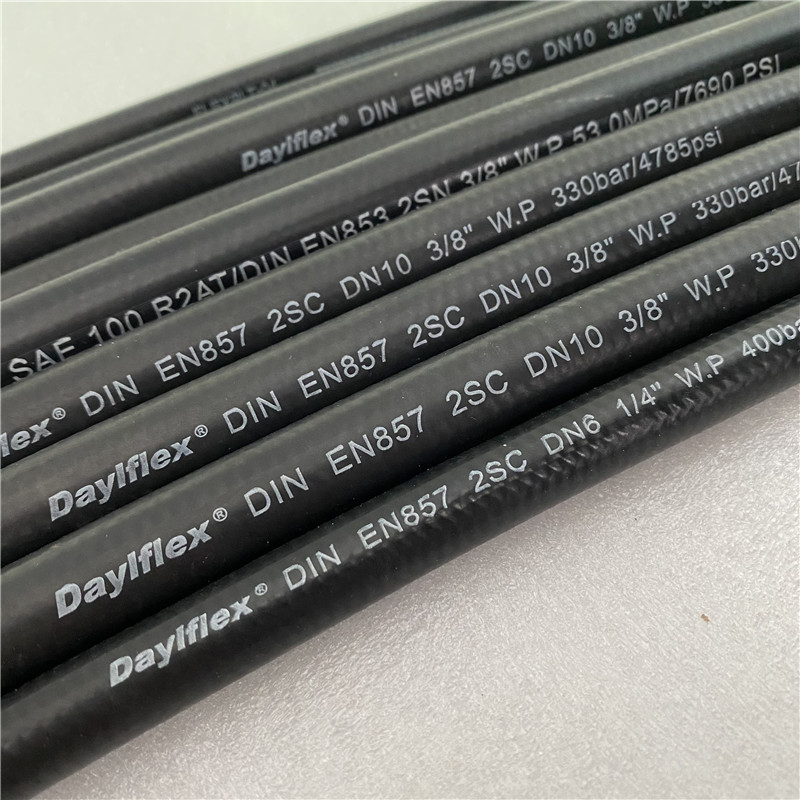

oem two fiber braid hydraulic hose manufacturers

Understanding OEM Two Fiber Braid Hydraulic Hose Manufacturers

In the world of hydraulic systems, hoses play a crucial role in transferring fluids under high pressure. Among the various types available, the OEM two fiber braid hydraulic hoses stand out due to their durability, flexibility, and resistance to various external factors. This article explores the significance of these hoses, the OEM manufacturers behind them, and the advantages they provide in various applications.

What is OEM Two Fiber Braid Hydraulic Hose?

OEM, or Original Equipment Manufacturer, refers to companies that produce parts and equipment that may be marketed by another manufacturer. In this context, OEM two fiber braid hydraulic hoses are those produced specifically for use within hydraulic systems, featuring two layers of braided fibers that enhance their strength and performance. The braid construction, often made of polyester or nylon, helps to reinforce the hose against high pressure, wear, and abrasions. This design also assists in maintaining flexibility, allowing for easier installation in tight spaces.

The Importance of Quality in Manufacturing

When it comes to hydraulic hoses, quality cannot be compromised. Poorly manufactured hoses can lead to leaks, bursts, and ultimately catastrophic failures that may endanger equipment and personnel. This is where OEM manufacturers come into play. Reputable OEM manufacturers adhere to strict quality control standards and are equipped with advanced technology and materials. They understand the harsh environments in which these hoses operate and design them to withstand high temperatures, chemicals, and mechanical stress.

Key Features of OEM Two Fiber Braid Hydraulic Hoses

1. High Pressure Resistance These hoses are engineered to handle high pressure, which is essential in hydraulic systems. The two fiber braid provides extra reinforcement, reducing the risk of failure under extreme conditions.

2. Flexibility The braided construction allows for greater flexibility compared to traditional rubber hoses. This adaptability is vital in applications where the routing of hoses can be complex.

3. Chemical Resistance Many OEM manufacturers formulate their hoses with materials that resist degradation from various oils, fluids, and chemicals, increasing the longevity of the hose.

4. Abrasion Resistance The outer layer of the hose is often treated to resist abrasion, protecting it from wear caused by friction and contact with surrounding equipment.

5. Compatibility OEM hoses are designed to meet or exceed industry standards, ensuring compatibility with different hydraulic systems and components.

Applications of OEM Two Fiber Braid Hydraulic Hoses

oem two fiber braid hydraulic hose manufacturers

The versatility of these hydraulic hoses makes them suitable for a wide array of applications across different industries. Some common applications include

- Construction Equipment Hydraulic hoses are vital in heavy machinery like excavators, bulldozers, and cranes, where they facilitate the movement of hydraulic fluids for various operations.

- Agricultural Machinery Farmers rely on hydraulic hoses for tractors and other farming equipment, where they assist in powering attachments and implements.

- Automotive Services In automotive repair shops, hooks enable the operation of hydraulic lifts, brakes, and other systems requiring hydraulic fluid transfer.

- Manufacturing Many manufacturing processes use hydraulic machines for pressing, cutting, and forming materials, underscoring the importance of reliable hoses in production lines.

Selecting the Right OEM Manufacturer

When it comes to choosing an OEM two fiber braid hydraulic hose manufacturer, several factors should be considered

- Reputation Look for manufacturers with a strong track record of quality and reliability. Reviews and testimonials can provide insight into a manufacturer’s performance.

- Certifications Ensure that the manufacturer meets relevant industry standards and holds certifications that demonstrate their commitment to quality.

- Customization Options Some applications require specific lengths, diameters, or additional features. Manufacturers offering customization can cater to unique needs.

- Technical Support Reliable manufacturers provide customer service and technical support, helping clients select the right hoses for their specific applications.

Conclusion

In summary, OEM two fiber braid hydraulic hoses are integral components in hydraulic systems across multiple industries. Their durability, flexibility, and resistance to harsh conditions make them a preferred choice among engineers and equipment manufacturers. Choosing the right OEM manufacturer is critical to ensuring the performance and safety of hydraulic applications. With the growing demand for quality hydraulic solutions, OEM manufacturers continue to innovate and enhance their offerings, paving the way for safer and more efficient industrial operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025