335345435

Nov . 05, 2024 12:31 Back to list

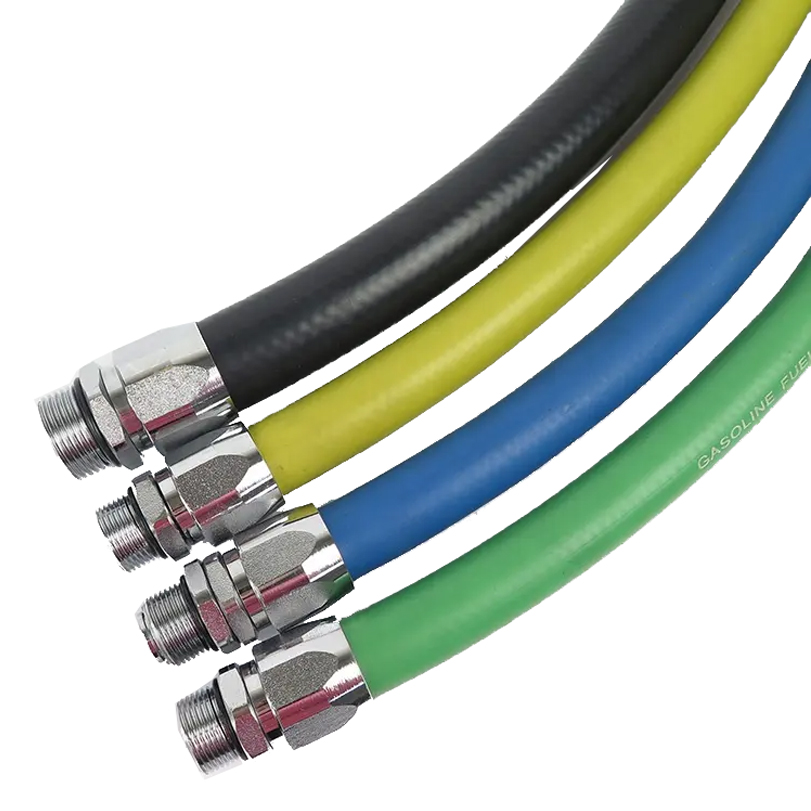

oem teflon ptfe hose factories

Exploring OEM Teflon PTFE Hose Factories Quality, Innovation, and Customization

In the realm of industrial applications, hoses play a crucial role in the efficient transfer of liquids and gases. Among the various types of hoses available, Teflon PTFE (Polytetrafluoroethylene) hoses stand out due to their remarkable properties, including their resistance to high temperatures, chemical reactivity, and non-stick characteristics. This article delves into the significance of OEM Teflon PTFE hose factories, exploring their contributions to quality, innovation, and customization in industrial sectors.

Understanding Teflon PTFE Hoses

Teflon PTFE hoses are known for their exceptional chemical resistance, which makes them ideal for use in industries such as pharmaceuticals, food processing, and petrochemicals. The unique molecular structure of PTFE allows these hoses to withstand extreme temperatures, ranging from -200°C to 260°C, making them suitable for both high and low-temperature applications. Furthermore, Teflon’s non-stick properties prevent materials from adhering to the hose, ensuring smooth flow and easy cleaning.

The Role of OEM Factories

OEM (Original Equipment Manufacturer) Teflon PTFE hose factories play a pivotal role in producing these specialized hoses. Unlike standard manufacturers, OEMs focus on creating products that meet specific customer requirements. This customization is essential in industries where standard hoses might not suffice due to unique operational conditions.

Working with OEM factories allows companies to develop hoses tailored to their specifications, including dimensions, pressure ratings, and compatibility with various chemicals. The collaboration between end-users and OEM manufacturers fosters innovation, as factories can incorporate the latest technologies and materials to enhance hose performance.

Quality Assurance in Production

Quality is paramount when it comes to manufacturing Teflon PTFE hoses. OEM factories often implement stringent quality control measures throughout the production process. This includes sourcing high-grade raw materials, adhering to international manufacturing standards, and conducting comprehensive testing of finished products.

oem teflon ptfe hose factories

Modern OEM Teflon PTFE hose factories employ advanced manufacturing techniques, such as extrusion and mandrel wrapping, to produce hoses that meet precise specifications. These methods not only guarantee uniformity but also enhance the durability and longevity of the hoses.

Moreover, reputable OEM factories utilize advanced testing methods, including pressure testing, chemical compatibility assessments, and environmental testing, to ensure that their hoses can withstand the rigors of industrial applications.

Innovation in Design and Manufacturing

The continuous demand for improved performance and efficiency drives innovation within OEM Teflon PTFE hose factories. Many manufacturers invest in research and development to explore new designs, coatings, and assembly techniques. For instance, innovations such as multi-layered hoses combine PTFE with other materials to enhance flexibility and minimize weight without compromising durability.

Moreover, the integration of smart technologies into hose manufacturing is on the rise. Some OEM factories are developing hoses equipped with sensors that monitor pressure, temperature, and chemical exposure in real time. This development not only enhances safety but also facilitates predictive maintenance, allowing companies to address potential issues before they escalate.

Sustainability Considerations

As industries increasingly prioritize sustainability, OEM Teflon PTFE hose factories are also exploring eco-friendly practices. Many manufacturers are adopting greener production methods, reducing waste, and enhancing the recyclability of materials. By striving for sustainable manufacturing processes, these factories are not only improving their environmental footprint but also meeting the growing demand for sustainable products in the market.

Conclusion

OEM Teflon PTFE hose factories are integral to the supply chain that supports various industries worldwide. Through their commitment to quality, innovation, and customization, these manufacturers contribute significantly to enhancing the performance and reliability of industrial hoses. As technology advances and sustainability becomes more critical, OEM factories are poised to lead the charge in developing next-generation hoses that meet the evolving needs of modern industries. By partnering with these specialized manufacturers, companies can ensure they have access to the best products tailored to their unique operational challenges.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025