335345435

Dec . 01, 2024 23:41 Back to list

oem stainless steel braided hose

The Versatility and Advantages of OEM Stainless Steel Braided Hoses

Stainless steel braided hoses have become a significant component in various industries, owing to their remarkable strength, durability, and flexibility. When we talk about OEM stainless steel braided hoses, we refer to Original Equipment Manufacturer (OEM) products designed to meet specific requirements of machinery and equipment. These hoses are engineered to endure extreme conditions while providing reliable performance, making them an indispensable item in automotive, aerospace, chemical, and food processing applications.

What are Stainless Steel Braided Hoses?

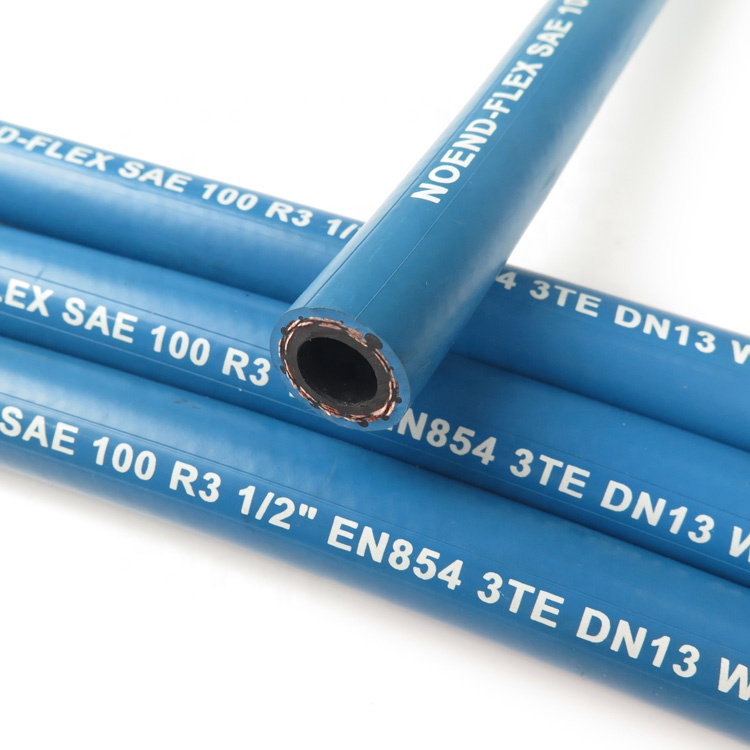

Stainless steel braided hoses are composed of a flexible inner conduit, typically made from rubber or thermoplastic materials, which is reinforced with a tightly woven braid of stainless steel wire. This design not only enhances the mechanical strength of the hose but also protects it from abrasions and extreme temperatures.

Benefits of OEM Stainless Steel Braided Hoses

1. Durability and Longevity One of the primary advantages of stainless steel braided hoses is their exceptional durability. The stainless steel braid provides superior resistance to wear and tear, making these hoses suitable for high-pressure applications where traditional rubber hoses may fail. Moreover, the corrosion-resistant properties of stainless steel extend the product's lifespan, minimizing the need for frequent replacements.

2. High Resistance to Extreme Temperatures Stainless steel braided hoses are designed to perform effectively within a wide temperature range. Whether in high-heat environments, such as exhaust systems, or in applications involving freezing temperatures, these hoses maintain their integrity, ensuring safety and efficiency in operations.

3. Flexibility and Customization OEM stainless steel braided hoses can be manufactured to specific dimensions and configurations to fit unique application requirements. This flexibility allows engineers and designers to incorporate these hoses into their systems without the worry of compatibility issues. Additionally, OEM manufacturers can accommodate custom specifications, such as varying lengths, diameters, and connection types.

oem stainless steel braided hose

4. Chemical Resistance Many industries require hoses that can withstand chemical exposure without degrading. Stainless steel braided hoses can resist corrosion from various chemicals, making them ideal for applications in pharmaceuticals, food and beverage processing, and petrochemical industries. This resilience ensures that the hose does not compromise the integrity of the fluids being transported.

5. Enhanced Safety Features The robust construction of stainless steel braided hoses contributes to enhanced safety in operations. Unlike traditional rubber hoses that can swell or burst under pressure, the reinforced design of stainless steel hoses maintains structural integrity, significantly reducing the risk of leaks or ruptures that can lead to dangerous situations.

6. Aesthetic Appeal In addition to their functional benefits, stainless steel braided hoses often possess an attractive finish. This aesthetic appeal makes them suitable not only for industrial applications but also for automotive customization, where appearance is as important as performance.

Applications of OEM Stainless Steel Braided Hoses

The versatility of OEM stainless steel braided hoses enables their use across numerous sectors

- Automotive Industry These hoses are frequently utilized in fuel lines, coolant transfer, and brake systems due to their ability to handle high pressures and temperatures. - Aerospace In aviation, the reliability of these hoses is critical. They are deployed in fuel systems and hydraulic applications where failure is not an option. - Chemical Processing Their chemical resistance makes them essential for transporting corrosive substances safely. - Food and Beverage In this sector, stainless steel hoses ensure that food products remain uncontaminated while being transported or processed.

Conclusion

In summary, OEM stainless steel braided hoses provide an exceptional solution for a wide array of industrial needs. Their combination of durability, flexibility, chemical resistance, and safety features make them an essential component in many applications. As industries continue to evolve, the demand for reliable and efficient fluid transfer solutions will only increase, solidifying the place of stainless steel braided hoses at the forefront of engineering innovations. For anyone in need of high-performance hoses, choosing OEM stainless steel braided options is a decision grounded in reliability and quality assurance.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025