335345435

Sep . 29, 2024 08:02 Back to list

OEM SAE 100R9 Hydraulic Hose Manufacturer and Supplier for High-Pressure Applications

Understanding OEM SAE 100R9 A Guide to High-Pressure Hose Manufacturing

When it comes to hydraulic applications, the choice of hoses is critical for ensuring efficiency and safety. Among the various hose standards, the SAE 100R9 is highly regarded, especially in industrial sectors that necessitate high-pressure hydraulic systems. This article delves into the nuances of OEM (Original Equipment Manufacturer) productions of hoses conforming to the SAE 100R9 specifications, exploring their construction, applications, and the importance of sourcing from reputable manufacturers.

What is SAE 100R9?

SAE 100R9 is a specification defined by the Society of Automotive Engineers (SAE), outlining the requirements for high-pressure hydraulic rubber hoses. Designed for transferring hydraulic fluids, these hoses can handle high pressure and high-temperature conditions. The SAE 100R9 hoses are constructed with multiple layers, combining synthetic rubber and reinforced materials that enhance durability and resilience against wear and tear.

Construction of SAE 100R9 Hoses

The construction of SAE 100R9 hoses is paramount to their performance

. Typically, these hoses consist of three main components1. Inner Tube Made from oil-resistant synthetic rubber, the inner tube is designed to withstand high pressures and hydrocarbon fluids, ensuring optimal fluid transfer without degradation.

2. Reinforcement Layer The strength and durability of SAE 100R9 hoses come from their reinforcement layers, usually crafted from high-tensile steel wire braids. This layer provides the necessary resistance to bursting under pressure, making them suitable for high-stress environments.

3. Outer Cover The outer surface is crafted from a weather-resistant component that protects against external elements like oil, ozone, and other harsh conditions. This protection ensures the longevity of the hose in various applications.

Applications of SAE 100R9 Hoses

Due to their robust nature, SAE 100R9 hoses find applications in several industries, including

- Construction Equipment Machines such as excavators and bulldozers utilize these hoses to operate hydraulic systems effectively, ensuring optimal performance.

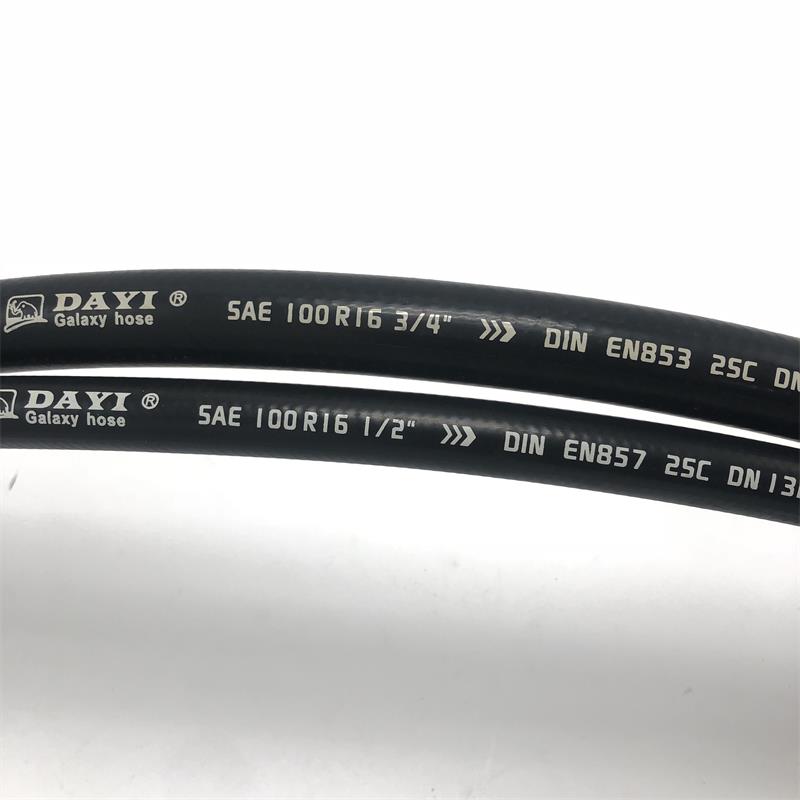

oem sae100r9 factory

- Mining Operations The harsh conditions of mining require hoses that can withstand high pressures and chemical exposure. SAE 100R9 hoses meet these demands, providing reliable performance.

- Agricultural Equipment Tractors and harvesters often rely on hydraulic systems powered by hoses that conform to SAE 100R9 standards, allowing them to perform efficiently.

- Oil and Gas Industry In environments where fluids are rigorously transferred, the SAE 100R9 hoses ensure minimal risk of leakage, thus maintaining safety and efficiency.

The Importance of OEM Manufacturing

When sourcing SAE 100R9 hoses, opting for OEM manufacturers is crucial. OEM production ensures that the hoses adhere strictly to SAE specifications, offering a quality assurance that generic manufacturers might not provide. The use of high-quality materials, advanced manufacturing processes, and stringent quality control measures makes OEM hoses more reliable.

Benefits of Choosing OEM

1. Quality Assurance OEM manufacturers are known for maintaining high standards in production. This ensures that the hoses you receive will meet or exceed the required specifications.

2. Customization Options Many OEM manufacturers offer the possibility of customizing hoses to meet specific requirements, allowing customers to source products tailored to their particular needs.

3. After-Sales Support Established OEMs often provide excellent customer service and support, aiding clients in resolving any issues that may arise post-purchase.

4. Safety Compliance Adhering to recognized standards, OEM products are compliant with safety regulations, playing a crucial role in the overall safety framework of hydraulic systems.

Conclusion

In conclusion, the OEM SAE 100R9 hoses are the backbone of many industrial applications, providing high reliability and performance under demanding conditions. Choosing hoses manufactured by reputable OEMs not only ensures compliance with safety standards but also contributes to the efficiency and longevity of hydraulic machinery. As industries continue to evolve and expand, the importance of high-quality hydraulic hoses like SAE 100R9 will remain paramount, cementing their role in the future of industrial efficiency and safety. Whether you’re in construction, mining, agriculture, or oil and gas, considering OEM SAE 100R9 hoses is an investment in quality and reliability.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025