335345435

Oct . 12, 2024 08:33 Back to list

OEM Suppliers for SAE 100R8 High-Pressure Hydraulic Hose Solutions

The Importance of OEM SAE 100R8 Suppliers in the Hydraulic Hose Industry

In the hydraulic hose industry, the significance of quality and reliability cannot be overstated. Original Equipment Manufacturer (OEM) suppliers play a critical role in ensuring that the hydraulic products used in various applications, from automotive to industrial machinery, meet strict safety and performance standards. One such essential standard is the SAE 100R8, which is widely recognized in the market. This article delves into the importance of OEM SAE 100R8 suppliers, their contributions to the industry, and the factors to consider when selecting a supplier.

Understanding SAE 100R8

SAE 100R8 is a designation provided by the Society of Automotive Engineers (SAE) for thermoplastic hydraulic hose. This hose is designed to handle high-pressure hydraulic fluids in both hydraulic systems and mobile equipment. The construction of SAE 100R8 typically involves a double-layer design that reinforces the hose, ensuring it can withstand the demanding conditions commonly found in hydraulic applications. Key applications include construction, agriculture, and various industrial processes, where reliability is paramount.

Role of OEM Suppliers

OEM suppliers of SAE 100R8 hoses are essential for manufacturing high-quality hydraulic systems. They develop hoses that not only comply with SAE specifications but also meet the unique requirements of different machines and applications. Some of the crucial roles that these suppliers play include

1. Quality Assurance OEM suppliers adhere to stringent quality control measures as they produce hoses according to industry standards. By ensuring that products meet ISO and SAE guidelines, these suppliers contribute to the overall safety and efficiency of hydraulic systems.

2. Custom Solutions Many OEM suppliers offer customized SAE 100R8 hoses designed to meet specific customer needs. This customization can involve changes in length, diameter, and material formulation, allowing manufacturers to optimize performance for particular applications.

3. Technical Expertise OEM suppliers often possess extensive industry knowledge, enabling them to offer valuable advice to their clients. Whether it’s selecting the right hose for a specific application or understanding compatibility with certain fluids, their expertise can be a vital resource.

4. Innovation and Development The hydraulic industry is ever-evolving, with ongoing advancements aimed at improving efficiency and durability. OEM suppliers invest in research and development to innovate new hose designs, materials, and manufacturing processes that can enhance performance.

oem sae100r8 supplier

Selecting the Right OEM Supplier

Choosing the right OEM SAE 100R8 supplier is a critical decision for any equipment manufacturer or engineer. Here are several key factors to consider

1. Certification and Compliance Ensure that the supplier is compliant with relevant industry standards, including those set by SAE, ISO, and other regulatory bodies. This certification is a testament to their commitment to quality.

2. Reputation and Experience Research the supplier's history and reputation within the industry. An established supplier with a good track record is more likely to provide reliable products and services.

3. Product Range Evaluate the supplier's product offerings. A supplier with a diverse range of products, including various sizes and custom hoses, is more likely to meet specific requirements.

4. Customer Support Look for suppliers who offer robust customer support, including technical assistance, troubleshooting, and after-sales services. Good communication and support can significantly enhance the purchasing experience.

5. Cost and Value While cost is an important consideration, it should not come at the expense of quality. Assess the value provided by the supplier, factoring in durability, performance, and warranty terms.

Conclusion

OEM SAE 100R8 suppliers play a pivotal role in the hydraulic hose industry, ensuring the integrity and performance of hydraulic systems across various applications. Their focus on quality, customization, technical expertise, and innovation enables them to meet the evolving needs of the market. By carefully selecting the right supplier, manufacturers and engineers can ensure the efficiency and reliability of their hydraulic systems, leading to enhanced performance and safety in their operations. In an industry where failure is not an option, investing in quality through reliable OEM partnerships is essential.

-

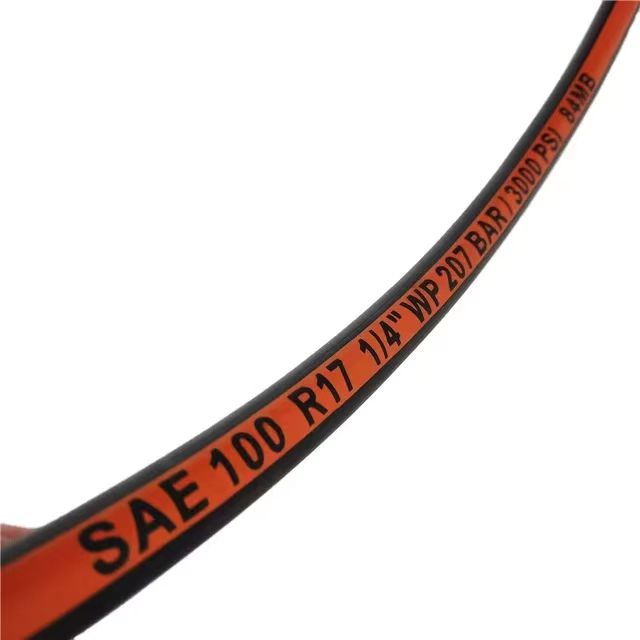

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025