335345435

Nov . 01, 2024 01:38 Back to list

OEM SAE100R2AT Hydraulic Hose Manufacturers and Suppliers for Quality Solutions

Understanding OEM SAE 100R2AT Hydraulic Hose Factories

In the realm of industrial equipment and machinery, hydraulic systems play a pivotal role. They are essential in various applications, from construction and agriculture to manufacturing and automotive industries. At the heart of these hydraulic systems lies the hydraulic hose, and specifically, the SAE 100R2AT hydraulic hose is among the most commonly used products. This article delves into the key aspects of OEM (Original Equipment Manufacturer) SAE 100R2AT hydraulic hose factories, exploring their significance, production processes, and market impact.

What is SAE 100R2AT?

SAE 100R2AT is a standardized specification set by the Society of Automotive Engineers. This type of hydraulic hose is designed to handle high pressure, specifically rated for pressures up to 4000 psi. It is constructed with an inner tube made from synthetic rubber, reinforced with two steel wire braids that add to its durability and strength. The outer cover typically features rubber compounds resistant to oil, abrasion, and weathering, making it suitable for a variety of hydraulic applications.

The Role of OEM Manufacturers

OEM manufacturers play a crucial role in the supply chain of hydraulic hoses. They are responsible for producing components and systems that meet specific requirements of other companies, often under their brand name. For the SAE 100R2AT hydraulic hose, OEM factories ensure that their products adhere to strict quality and safety standards, enabling companies to rely on their hoses for high-performance hydraulic applications.

Production Processes

The manufacturing process of SAE 100R2AT hydraulic hoses involves several stages

oem sae100r2at hydraulic hose factories

1. Material Selection High-quality materials are chosen to ensure reliability and durability. The inner tube, reinforcement, and outer cover materials are selected based on their ability to withstand high pressure and resist external conditions.

2. Wire Braiding The steel wire braiding process is critical as it provides the necessary strength to the hose. Two layers of steel wire are typically used to enhance the hose’s pressure rating.

3. Assembly After the braiding, the hoses are assembled by attaching the necessary fittings or connectors, ensuring a tight and secure fit for optimal performance.

4. Testing and Quality Control Each batch of hoses undergoes rigorous testing for pressure, flexibility, and overall quality. This ensures that every hose meets the SAE 100R2AT specifications and can withstand the demanding environments they will be subjected to.

5. Packaging and Shipping Finally, the hoses are carefully packaged and shipped to distributors or directly to OEM customers, ready for integration into various hydraulic systems.

The Market Impact

The demand for SAE 100R2AT hydraulic hoses is prevalent across multiple industries, driven by the need for reliable hydraulic systems. As machinery and equipment become more advanced, the specifications for hydraulic hoses also evolve, requiring manufacturers to innovate continuously. The OEM factories are tasked with not only meeting these requirements but also providing cost-effective solutions that ensure competitiveness in the global market.

In summary, OEM SAE 100R2AT hydraulic hose factories are integral to the hydraulic systems that power various industries. By adhering to high standards of quality and performance, these manufacturers play a vital role in ensuring that hydraulic applications operate smoothly and efficiently. As industries continue to grow and technology advances, the importance of reliable hydraulic components such as the SAE 100R2AT hose cannot be overstated. The future of hydraulic systems depends on the innovation and efficiency of these OEM manufacturers, ensuring they meet the ever-evolving demands of the market.

-

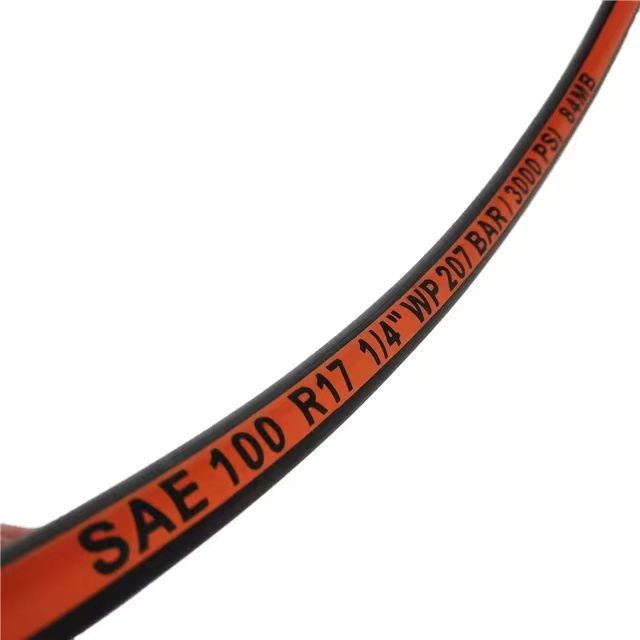

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025