335345435

Sep . 28, 2024 19:19 Back to list

OEM Rubber Air Hose Production and Supply for Industrial Applications and Custom Solutions

The Rising Demand for OEM Rubber Air Hose Manufacturers

In various industries, the importance of reliable air hoses can't be overstated. These components, integral to pneumatic systems, are critical for performance, safety, and durability. As businesses seek to optimize their operations, the demand for Original Equipment Manufacturer (OEM) rubber air hoses has risen sharply. This article explores the significance of OEM rubber air hose manufacturers and the factors attributing to their growing prominence in today's market.

Understanding OEM Rubber Air Hoses

OEM rubber air hoses are designed specifically for integration into new machinery or equipment produced by OEMs. They are typically made from high-quality rubber compounds that offer flexibility, resilience, and resistance to wear and tear. The primary purpose of these hoses is to convey compressed air in various applications, ranging from industrial machinery to automotive systems.

One of the key advantages of using OEM products is that they are engineered to meet specific standards and requirements set by manufacturers. This ensures a high level of compatibility and reliability. Unlike generic hoses, OEM rubber air hoses undergo rigorous testing to ensure they can withstand extreme conditions without failure.

Quality Assurance and Customization

One of the standout features of OEM rubber air hoses is the quality assurance provided by the manufacturers. Since these hoses are custom-made, they can be tailored to meet the precise specifications of a client’s machinery. This customization extends to various aspects, including diameter, length, pressure ratings, and material properties.

Additionally, OEM manufacturers boast robust quality control processes to ensure each hose meets industry standards. This often results in prolonged service life and fewer operational disruptions, making them a cost-effective choice in the long run. Businesses that invest in high-quality OEM rubber air hoses often experience reduced maintenance costs and improved efficiency.

Rise of Globalization and Technological Advancements

oem rubber air hose manufacturer

The demand for OEM rubber air hoses has also been amplified by globalization and advancements in technology. Manufacturers from different regions can now collaborate and reach wider markets. Moreover, innovative manufacturing processes such as the use of advanced rubber compounding technology and automated production systems have improved the quality and efficiency of air hoses.

Sustainable practices have also gained traction among OEM manufacturers. As environmentally conscious consumers rise, companies are increasingly focusing on producing eco-friendly rubber hoses that meet sustainability criteria, thereby catering to a broader audience while reducing their carbon footprint.

Industry Applications

OEM rubber air hoses are utilized across various industries, highlighting their versatility. The automotive sector relies on these hoses for air brake systems and pneumatic tools. In manufacturing, they are essential for powering machinery and pneumatic devices. Construction sites use these hoses for equipment that requires compressed air while maintenance and repair operations also depend on them for efficient service delivery.

As industries transition towards automation and more complex pneumatic systems, the demand for specialized OEM rubber air hoses is expected to grow. Enhanced features such as improved abrasion resistance, enhanced portability, and better adaptability to different climates are appealing attributes that many OEM manufacturers are now focusing on.

Conclusion

As global industries continue to evolve, the role of OEM rubber air hose manufacturers has become increasingly vital. Their commitment to quality, customization, and innovation ensures that businesses can operate efficiently and safely. The continuous rise in demand for these specialized air hoses illustrates how essential they are in facilitating a wide range of operations.

Investing in OEM rubber air hoses not only guarantees reliability but also significantly contributes to the overall efficiency of industrial processes. As the market for these components grows, so too does the opportunity for manufacturers to innovate and adapt to the needs of their clients. Ultimately, the partnership between industries and OEM manufacturers is likely to shape the future of pneumatic systems for years to come.

-

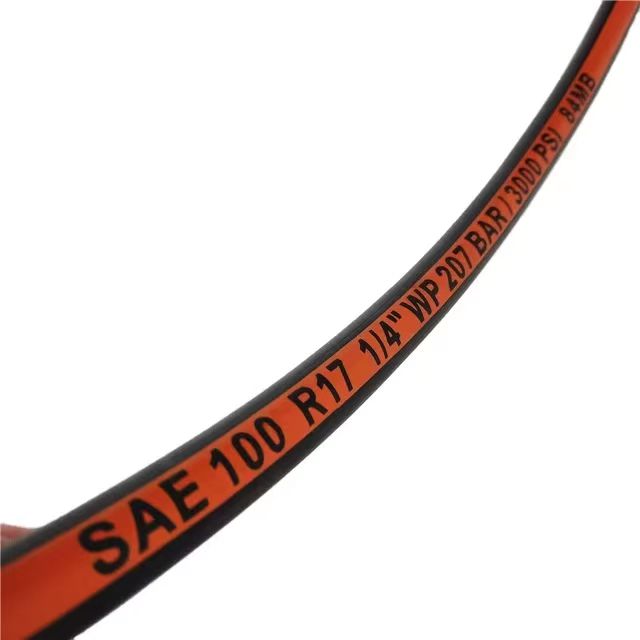

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025