335345435

Oct . 06, 2024 14:00 Back to list

oem red hydraulic hose factory

Exploring the OEM Red Hydraulic Hose Factory A Hub of Quality and Innovation

In today's industrial landscape, the demand for high-quality hydraulic hoses is on the rise, especially in sectors like manufacturing, construction, and automotive. One notable source of these essential components is the Original Equipment Manufacturer (OEM) red hydraulic hose factory. This factory embodies a commitment to quality, innovation, and customer satisfaction, making it a pivotal player in the hydraulic hose market.

Understanding Hydraulic Hoses

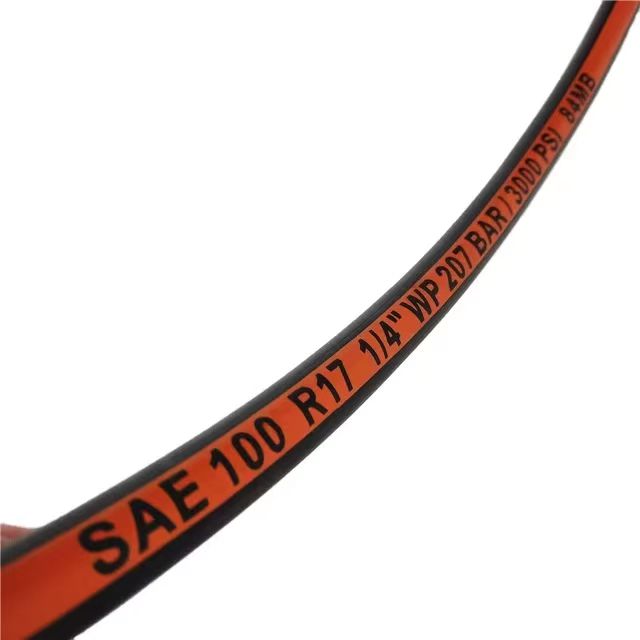

Hydraulic hoses are vital components in transferring fluid to various machinery and equipment. They are designed to withstand high pressures and provide excellent resistance to abrasion and weathering. The red hydraulic hoses produced in OEM factories often signify high performance and durability, appealing to industries that require reliable and efficient power transmission solutions.

The Importance of OEM in Hydraulic Hose Production

OEMs play an essential role in producing hydraulic hoses tailored to specific machinery requirements. Unlike generic aftermarket parts, OEM products are often created with precise engineering and testing. This ensures compatibility and peak performance, addressing the unique needs of each client.

When customers opt for OEM red hydraulic hoses, they are not merely purchasing a product; they are investing in a promise of quality and reliability. These hoses undergo rigorous testing to meet industry standards, ensuring they can withstand extreme conditions and retain their integrity over time.

The Manufacturing Process

The production of red hydraulic hoses at an OEM factory involves several critical steps. It starts with the selection of high-quality raw materials, often featuring reinforced synthetic rubber and steel wire for optimal strength. The rubber compounds used are designed specifically for hydraulic applications, enhancing flexibility, temperature tolerance, and resistance to leaks.

oem red hydraulic hose factory

Next, these materials are subjected to advanced manufacturing techniques, which could include extrusion, braiding, and curing. Each stage is meticulously monitored to ensure precision and consistency. The curled mandrel process is often employed to shape the hoses accurately, followed by thorough testing for pressure tolerance and flexibility. Quality control is paramount, with several checks throughout the manufacturing process to ensure that each hose meets or exceeds regulatory standards.

Technological Advancements

The OEM red hydraulic hose factory also embraces cutting-edge technology to enhance its production capabilities. Automation and sophisticated machinery have significantly improved efficiency and precision. Furthermore, the integration of computer-aided design (CAD) allows engineers to create custom solutions tailored to client specifications. This adaptability is particularly beneficial in industries where equipment specifications may vary.

Customer-Centric Approach

A cornerstone of the OEM red hydraulic hose factory's success is its customer-centric approach. Understanding the diverse needs of clients is crucial. This includes engaging with customers for feedback, offering extensive product catalogs, and providing expert guidance on hose selection. By prioritizing customer satisfaction, the factory builds long-term relationships and fosters loyalty.

Global Reach and Environmental Responsibility

In a globalized economy, the OEM red hydraulic hose factory has expanded its reach beyond national borders. It successfully caters to international markets, ensuring that its high-quality products are accessible worldwide. Furthermore, many OEMs are committed to sustainability, employing eco-friendly practices in their manufacturing processes to minimize environmental impact.

Conclusion

In conclusion, the OEM red hydraulic hose factory stands as a beacon of quality and innovation in the hydraulic hose industry. Through a combination of advanced manufacturing techniques, a commitment to customer satisfaction, and a focus on sustainability, it effectively meets the demands of modern industries. As the need for reliable hydraulic solutions continues to grow, the role of OEMs like this factory will remain critical in shaping the future of hydraulic technology. For industries reliant on hydraulic systems, investing in OEM products is not just a choice but a pathway to operational excellence and a sustainable future.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025